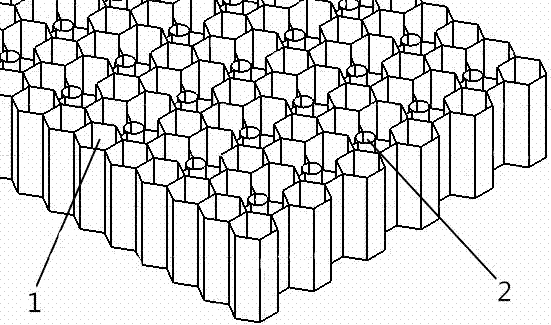

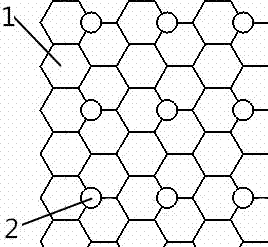

Regular-hexagon honeycomb core with detachable circular noise-reducing structures

A regular hexagonal and honeycomb core technology, applied in the field of aerospace composite materials, can solve the problems of invariable noise reduction performance, complex noise reduction performance, and irregular changes, etc., to achieve repeatable performance design, simple and flexible changes, and low noise reduction. The effect of improved noise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

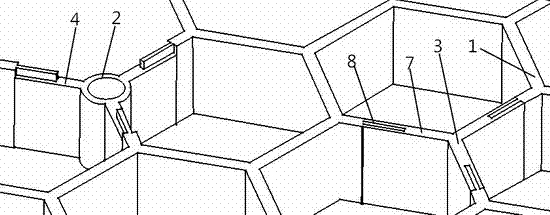

[0034] Example 1: Please refer to Figure 1-4 , Figure 9-10 , Figure 11-12 , Figure 15-16The circular honeycomb (2) structure is composed of a hollow aluminum cylinder and three aluminum plates with rectangular grooves at 120° to each other. The aluminum plate (4) of the circular honeycomb structure is connected to the main structure of the regular hexagonal honeycomb (1) There is a rectangular groove at one end. The geometric dimensions of the end of the connection between the missing wall plate (5) and the circular honeycomb (2) structure of the regular hexagonal honeycomb structure are the same as the geometric dimensions of the rectangular groove (6) of the aluminum plate of the circular honeycomb structure. The wall plate (5) where the honeycomb part is missing is inserted into the rectangular groove (6) of the aluminum plate of the circular honeycomb structure. The regular hexagonal honeycomb (1) main structure and the circular honeycomb (2) structure are fastened...

Embodiment 2

[0038] Example 2: Please refer to Figure 1-2 , Figure 5-6 , Figure 9-10 , Figure 13-14 , Figure 17-18 , the circular honeycomb (2) structure is composed of an aluminum hollow cylinder and three aluminum plates that are 120° to each other. The missing wall plate (5) of the regular hexagonal honeycomb is connected to the circular honeycomb (2) and has a rectangular concave at one end. The geometric dimensions of the aluminum plate at one end of the connection between the aluminum plate (4) of the circular honeycomb structure and the main structure of the regular hexagonal honeycomb (1) are the same as the geometric dimensions of the rectangular slot (9) of the wall plate where the regular hexagonal honeycomb part is missing. The aluminum plate (4) of the circular honeycomb structure is inserted into the rectangular groove (9) of the wall plate where the regular hexagonal honeycomb part is missing. The regular hexagonal honeycomb (1) main structure and the circular honey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com