Multi-functional building exterior wall environment-friendly nano-coating and preparation method thereof

A multi-functional technology for building exterior walls, applied in coatings and other directions, can solve the problems of poor dispersion of nano-fillers and poor coating film performance, and achieve the effects of excellent erosion resistance, strong adhesion and good film performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

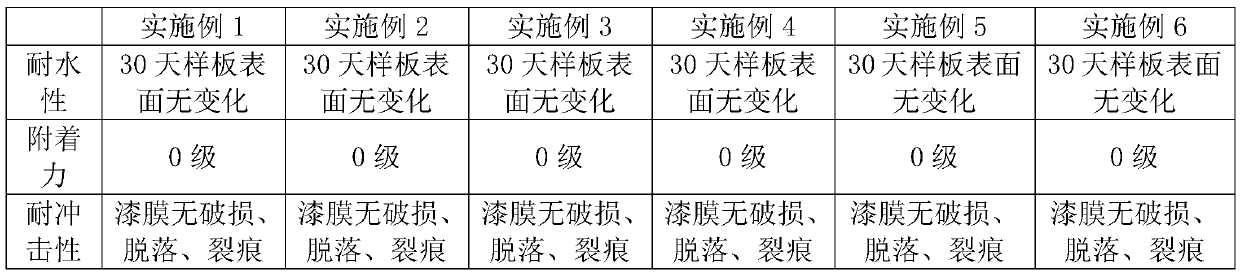

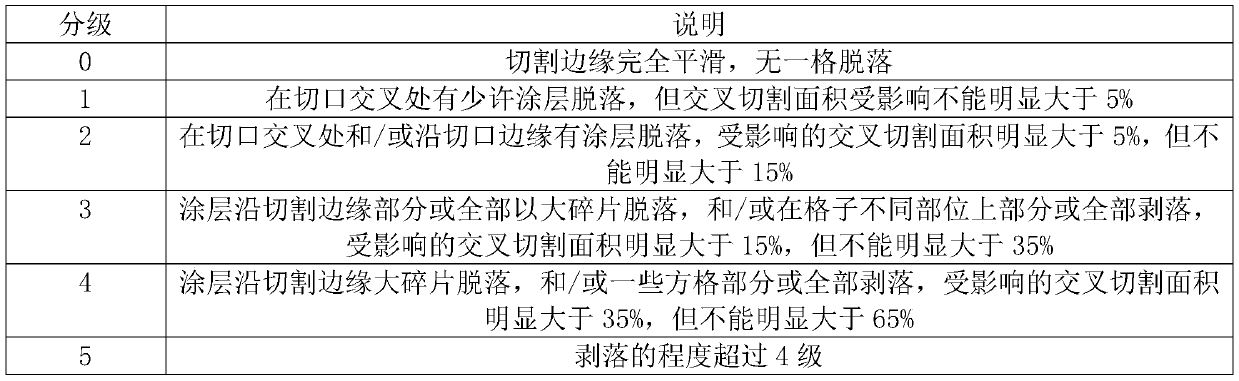

Examples

Embodiment 1

[0046] A kind of environmental protection green coating of multi-functional nano building external wall, by weight, comprises following component:

[0047] 20 parts of water-based acrylic emulsion, 4 parts of butyl acrylate,

[0048] Nano-TiO 2 1 part, 1 part of pearlescent mica powder,

[0049] 0.5 parts of hollow glass microspheres, 0.8 parts of sodium hexametaphosphate,

[0050] 1.1 parts of ethoxylated alkylphenol ammonium sulfate, 0.5 parts of propyltrimethoxysilane,

[0051] 2 parts of pH regulator, 2 parts of other additives, 10 parts of deionized water.

[0052] Its preparation method comprises the following steps:

[0053] (1) Nano-TiO 2 , Pearlescent mica powder, hollow glass microspheres, sodium hexametaphosphate and deionized water were mixed and stirred evenly, ultrasonicated for 1 hour at a power of 500W, continued to add other additives, and continued ultrasonicated for 30 minutes to obtain a dispersion;

[0054] (2) Add water-based acrylic emulsion, butyl...

Embodiment 2

[0056] A kind of environmental protection green coating of multi-functional nano building external wall, by weight, comprises following component:

[0057] 50 parts of water-based acrylic emulsion, 8 parts of butyl acrylate,

[0058] Nano-TiO 2 2 parts, 1.5 parts of pearlescent mica powder,

[0059] 1 part of hollow glass microspheres, 1.2 parts of sodium hexametaphosphate,

[0060] 1.5 parts of ethoxylated alkylphenol ammonium sulfate, 1 part of propyltrimethoxysilane,

[0061] 3 parts of pH regulator, 5 parts of other additives, 20 parts of deionized water.

[0062] Its preparation method comprises the following steps:

[0063] (1) Nano-TiO 2 , Pearlescent mica powder, hollow glass microspheres, sodium hexametaphosphate and deionized water were mixed and stirred evenly, ultrasonicated for 3 hours at a power of 1000W, continued to add other additives, and continued ultrasonicated for 60 minutes to obtain a dispersion;

[0064] (2) Add water-based acrylic emulsion, butyl...

Embodiment 3

[0066] A kind of environmental protection green coating of multi-functional nano building external wall, by weight, comprises following component:

[0067] 50 parts of water-based acrylic emulsion, 6 parts of butyl acrylate,

[0068] Nano-TiO 2 1.5 parts, 1.3 parts of pearlescent mica powder,

[0069] 0.7 parts of hollow glass microspheres, 1 part of sodium hexametaphosphate,

[0070] 1.3 parts of ethoxylated alkylphenol ammonium sulfate, 1 part of propyltrimethoxysilane,

[0071] 2.5 parts of pH regulator, 4 parts of other additives, 20 parts of deionized water.

[0072] Its preparation method comprises the following steps:

[0073] (1) Nano-TiO 2 , Pearlescent mica powder, hollow glass microspheres, sodium hexametaphosphate and deionized water were mixed and stirred evenly, ultrasonicated for 1.5 hours at a power of 600W, continued to add other additives, and continued ultrasonicated for 35 minutes to obtain a dispersion;

[0074] (2) Add water-based acrylic emulsion, bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com