Fireproof insulation board and preparation method thereof

A heat insulation board and board technology, applied in the direction of chemical instruments and methods, lamination, lamination equipment, etc., can solve the problems of powder leakage, damage, loss of vacuum insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The present invention also provides a method for preparing the fireproof and heat insulating board described in the above technical solution, comprising the following steps:

[0069] a) covering the resin film on the reinforcement layer to obtain a reinforcement layer pasted with the resin film; the resin in the resin film is a flame retardant resin;

[0070] b) Covering the reinforced layer with the resin film attached to the airgel core material layer obtained in step a) on the upper and lower sides of the airgel core material layer, and then sealing the edges with resin at the edge of the airgel core material layer to obtain a prefabricated part;

[0071] c) performing hot-pressing treatment on the prefabricated part obtained in step b), and obtaining a fire-proof and heat-insulating board after cooling.

[0072] In the present invention, the resin film is firstly covered on the reinforcing layer to obtain the reinforcing layer pasted with the resin film. In the pre...

Embodiment 1

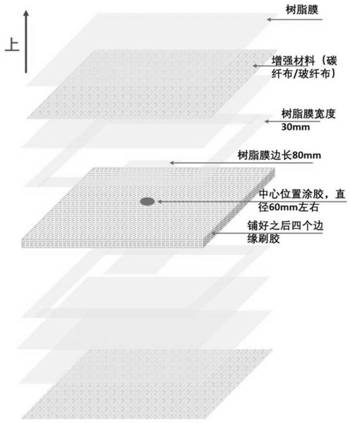

[0095] The structural schematic diagram (exploded view) of the fire-proof and heat-insulating panel provided by Embodiment 1 of the present invention can be found in image 3 shown.

[0096] Concrete preparation process is as follows:

[0097] (1) Add 200g / m 2 resin film (see Figure 4 As shown) covered on the glass fiber cloth, the glass fiber cloth located on the lower surface of the airgel core material is covered with 2 layers of resin film (the final 2 layers of resin film are both between the core material and the reinforcement layer), and the resin film is cut 30mm wide, paste it on the edge of the glass fiber cloth to enhance the bonding strength of the edge, cut the resin film into a square with a side length of 80mm, and paste it on the center of the glass fiber cloth, see Figure 5 As shown; the upper and lower sides of the glass fiber cloth on the upper surface of the airgel core material are covered with a layer of resin film (the final layer of resin film is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com