Method for constructing sunlight room roof and sunlight room roof

A sun room and main beam technology, applied in the field of sun room, can solve the problems of inconvenient disassembly, inconvenient operation, not firm and stable connection, etc., and achieve the effect of simple installation and processing, convenient disassembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

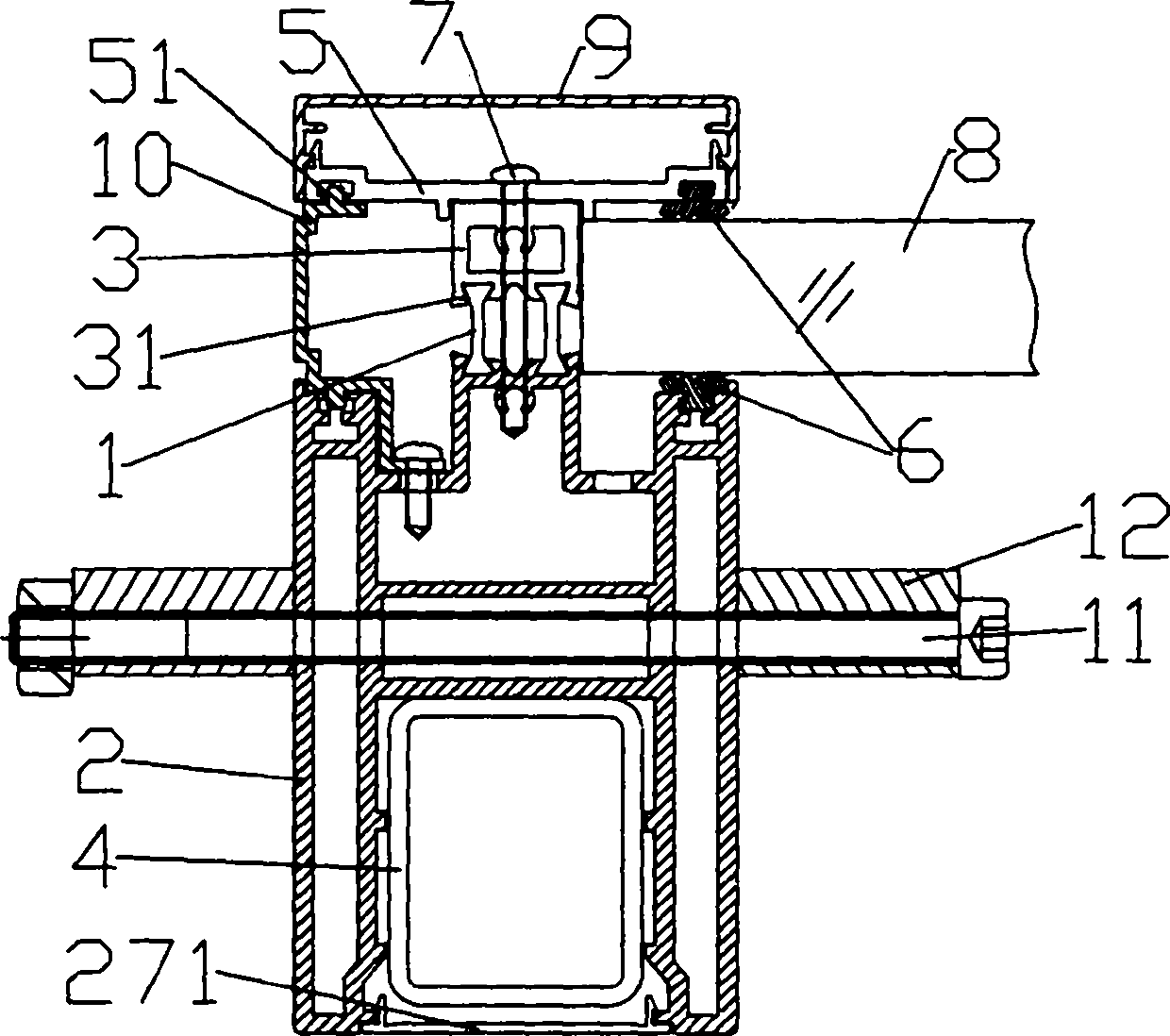

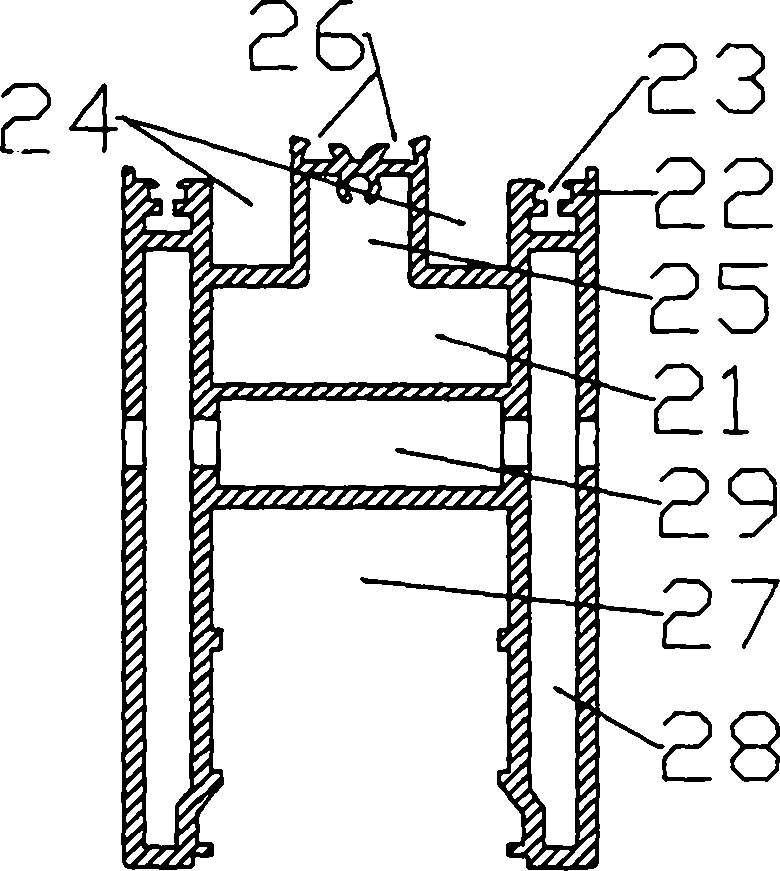

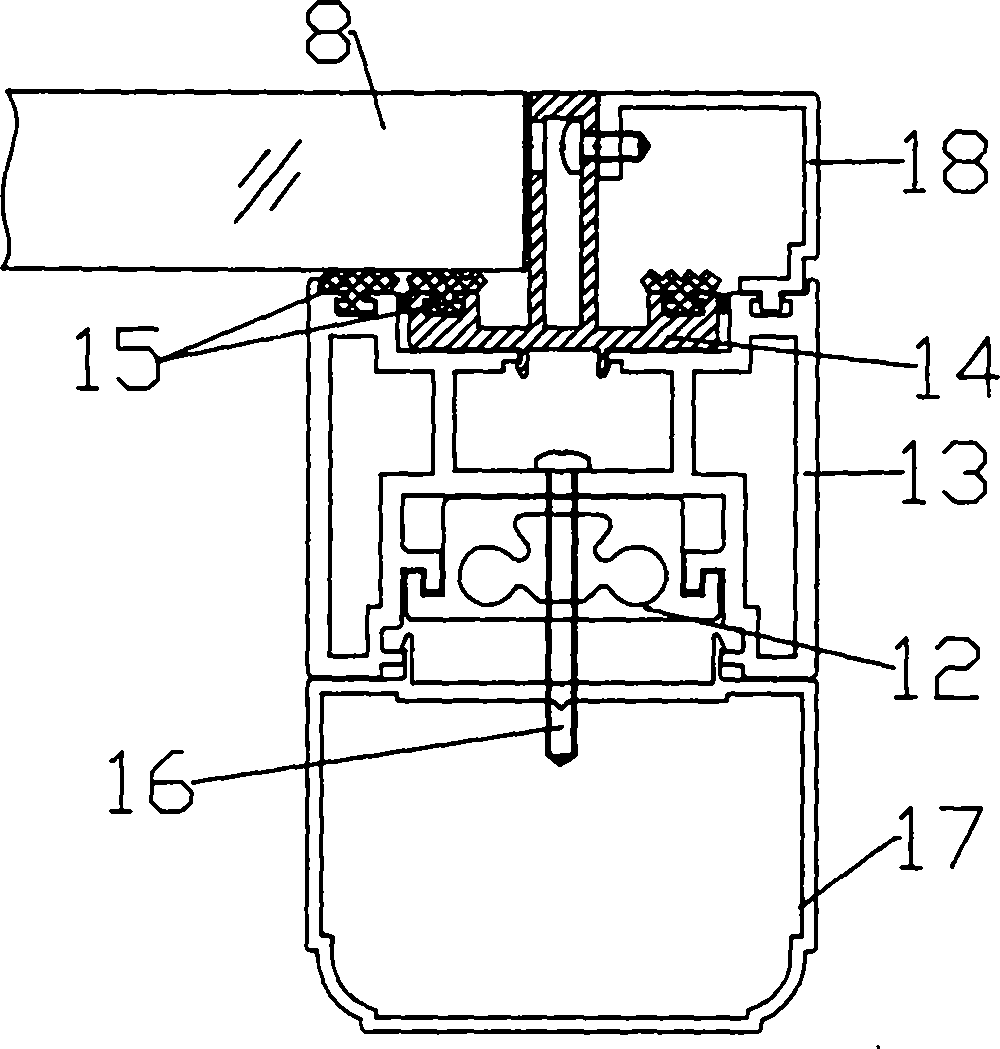

[0032] The method for building the roof of a sun room in the present invention comprises the following steps:

[0033] 1) The main beams and secondary beams are arranged at an angle to each other and fixedly connected to form frames for installing roof glass. Each main beam is inclined from the roof to the eaves. type of drainage structure;

[0034] 2) The roof glass is placed on the frame frame formed by the main beam and the secondary beam, and a sealing strip is arranged between the lower side of the roof glass and the main beam and the secondary beam, and the upper side of the roof glass is connected to the secondary beam. Sealing strips are installed between the main beams, and the sealing strips on the top and bottom of the roof glass are pressed tightly by screws to achieve sealing and waterproofing. The roof of the entire sun room adopts flowing drainage in the open area, and the infiltrated water passes through the main beams and The hidden drainage structures of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com