Animal leather yarn and its producing method

A technology of animal skin and animal skin fiber, applied in yarn, textile and papermaking, etc., can solve the problem of low utilization rate of animal skin leftovers and scraps, and achieve the effect of widening the scope of use, abundant resources and rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

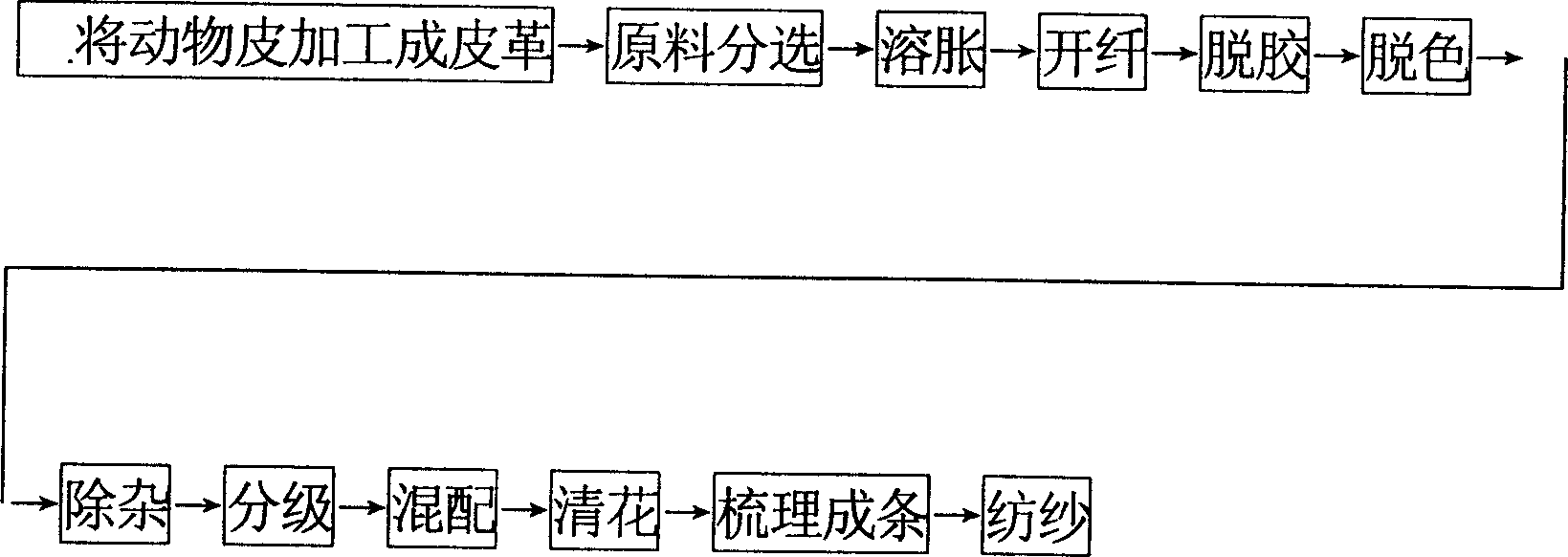

[0038] Embodiment 1: the production of kraft fiber

[0039] Sorting: Screening and sorting cowhide leather of different weights, thicknesses, and sizes, leftovers or recycled waste cowhide.

[0040] Swelling: Put the sorted cowhide into an aqueous solution with a liquid ratio of 500%, Remibang A2%, high-efficiency wetting agent 1.5%, and a temperature of 28-30°C, stir evenly, soak for 18 hours, wash with water, dehydrate, and cool. Dry.

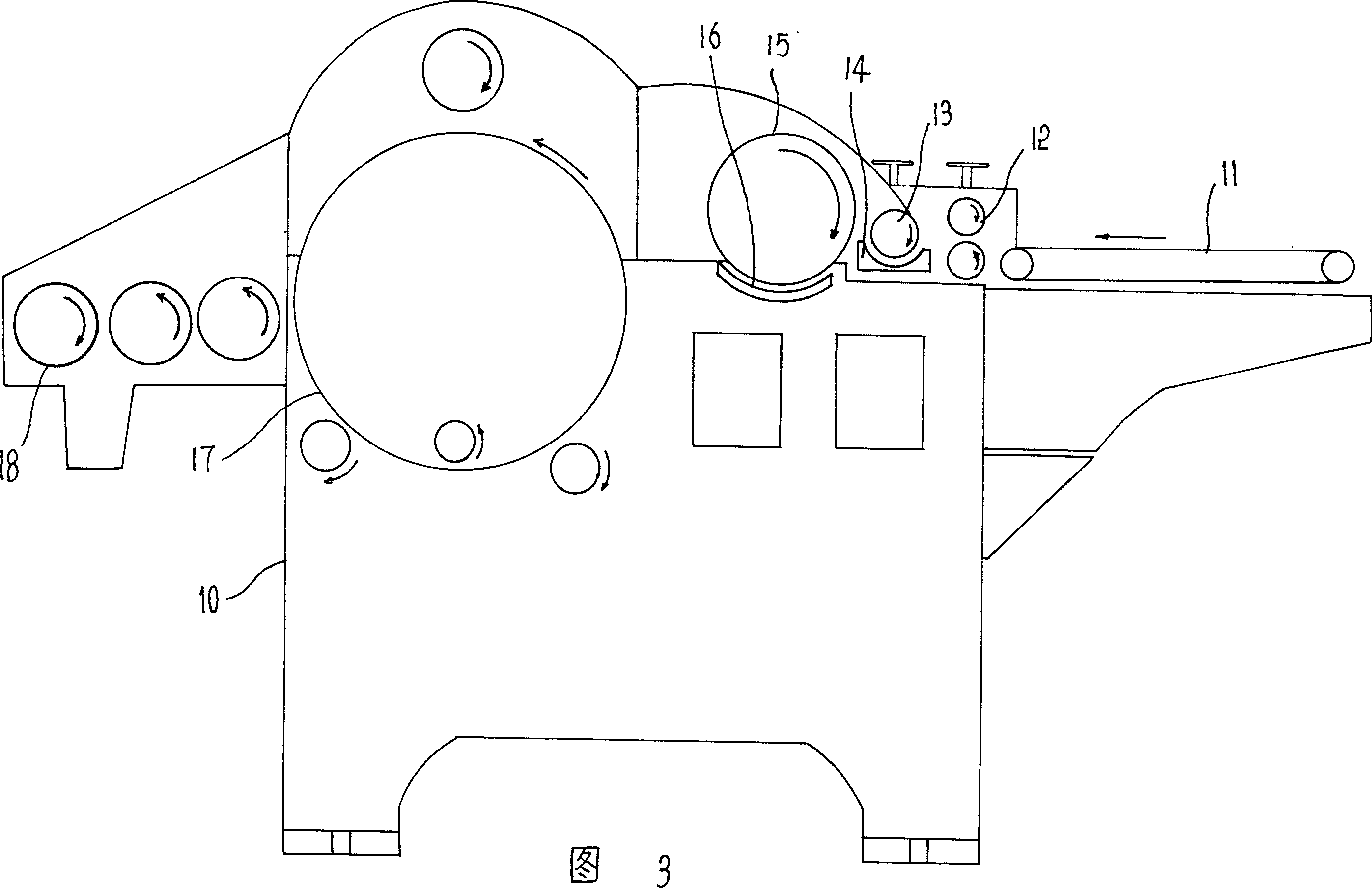

[0041] Fiber opening: Use a self-made fiber opening machine for fiber opening, and process the swollen cowhide leather into cowhide fibers with a thickness of 15-45mm and a fineness of 1D-2.3D.

[0042] Degumming: Put the opened kraft fiber into the degreased aqueous solution (PH value 7.5-9.0) with 5% anionic nonionic surfactant and 6% organic solvent added by weight, stir evenly at room temperature, and soak for 60 minutes , Wash with water, shake dry.

[0043] Decolorization: put the degummed kraft fiber into an aqueous solution added w...

Embodiment 2

[0046] Embodiment 2: the production of pigskin fiber

[0047] Swelling: put the sorted pigskin into an aqueous solution with a liquid ratio of 550%, Remybang A1.8%, high-efficiency wetting agent 1.3%, and a temperature of 28-30°C, stir evenly, soak for 16 hours, wash with water, and dehydrate , dry.

[0048] Fiber opening: Use a self-made fiber opening machine for fiber opening, and process the swollen pigskin leather into pigskin fibers with a thickness of 10-40mm and a fineness of 0.8D-2D.

[0049] Degumming: Put the loosened pigskin fiber into the degreasing aqueous solution (PH value 6.0-8.0) added with 5% by weight surfactant and 5% organic solvent, stir evenly at room temperature, soak for 45 minutes, wash with water , shake dry.

[0050] Decolorization: put the degummed pigskin fibers into an aqueous solution added with 5% by weight bleaching water at a temperature of 35-37° C., soak for 30 minutes, wash with water, and dry with hot air.

[0051] Other sorting, impur...

Embodiment 3

[0052] Embodiment 3: the production of goatskin fiber

[0053] Swelling: put the sorted goatskin into an aqueous solution with a liquid ratio of 600%, Remibang A1.5%, high-efficiency wetting agent 1%, and a temperature of 28-30°C, stir evenly, soak for 15 hours, wash with water, Dehydrate and dry.

[0054] Fiber opening: Use a self-made fiber opening machine for fiber opening, and process the swollen goatskin leather into goatskin fibers with a thickness of 16-30mm and a fineness of 0.3D-1D.

[0055] Degumming: Put the loosened goatskin fiber into the normal temperature aqueous solution (pH value 7.0-8.0) added with 10% by weight of AD leather degreasing agent, stir evenly, soak for 20 minutes, wash with water, and spin dry.

[0056] Decolorization: put the degummed goatskin fibers into an aqueous solution added with 5% by weight bleaching water at a temperature of 25-30° C., stir evenly for 30 minutes, wash with water, and dry with hot air.

[0057] Other sorting, impurity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com