Polyimide aerogel and preparation method thereof

A polyimide and aerogel technology, applied in the field of thermal insulation materials, can solve the problems of high equipment requirements, long time required and high cost, and achieve the effects of high mechanical strength, short time required and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a polyimide airgel, and its specific preparation steps are as follows:

[0037] Step 1: Preparation of water-soluble polyamic acid: use N,N-dimethylacetamide as solvent, carry out in ice-water bath by equimolar ratio of 4,4'-diaminodiphenyl ether and terephthalic anhydride The polyamic acid with a mass fraction of 15% was prepared by condensation polymerization. The specific process is as follows: Dissolve 8.0096g of 4,4'-diaminodiphenyl ether in 95.57g of N,N-dimethylacetamide, add 8.8556g of pyromellitic dianhydride, and carry out polymerization in an ice-water bath for 5h , to prepare a water-soluble polyamic acid solution with a mass fraction of 15%. The prepared water-soluble polyamic acid is poured into deionized water for precipitation to obtain a polyamic acid prepolymer, and then washed and freeze-dried to obtain a water-soluble polyamic acid fiber for use. This method refers to the patent "A graphene oxide / polyamic acid hydrogel with...

Embodiment 2

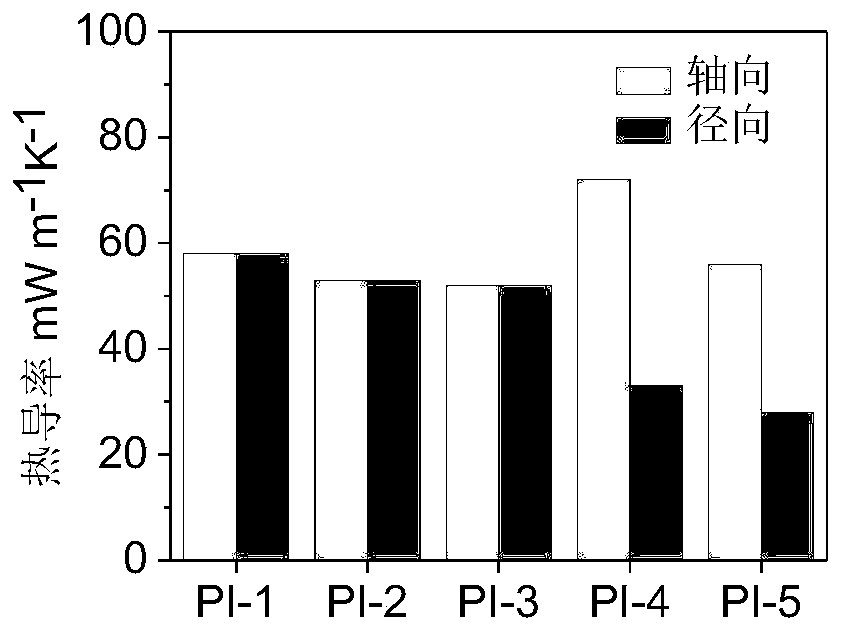

[0041] The difference between this example and Example 1 is that the mass fraction of polyamic acid in step 1 is 7%, and the deionized water in step 2 is 15g, and the obtained polyimide airgel is denoted as PI-2.

Embodiment 3

[0043] The difference between this example and Example 1 is that the amount of ethanol used in step 2 is 2 g, and the obtained polyimide airgel is denoted as PI-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com