Preparation of europium-doped yttrium borate spherical luminescent material

A spherical luminescence, yttrium europium borate technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of reducing the brightness of phosphors, difficult to control the morphology, etc., and achieve the effect of uniform size and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

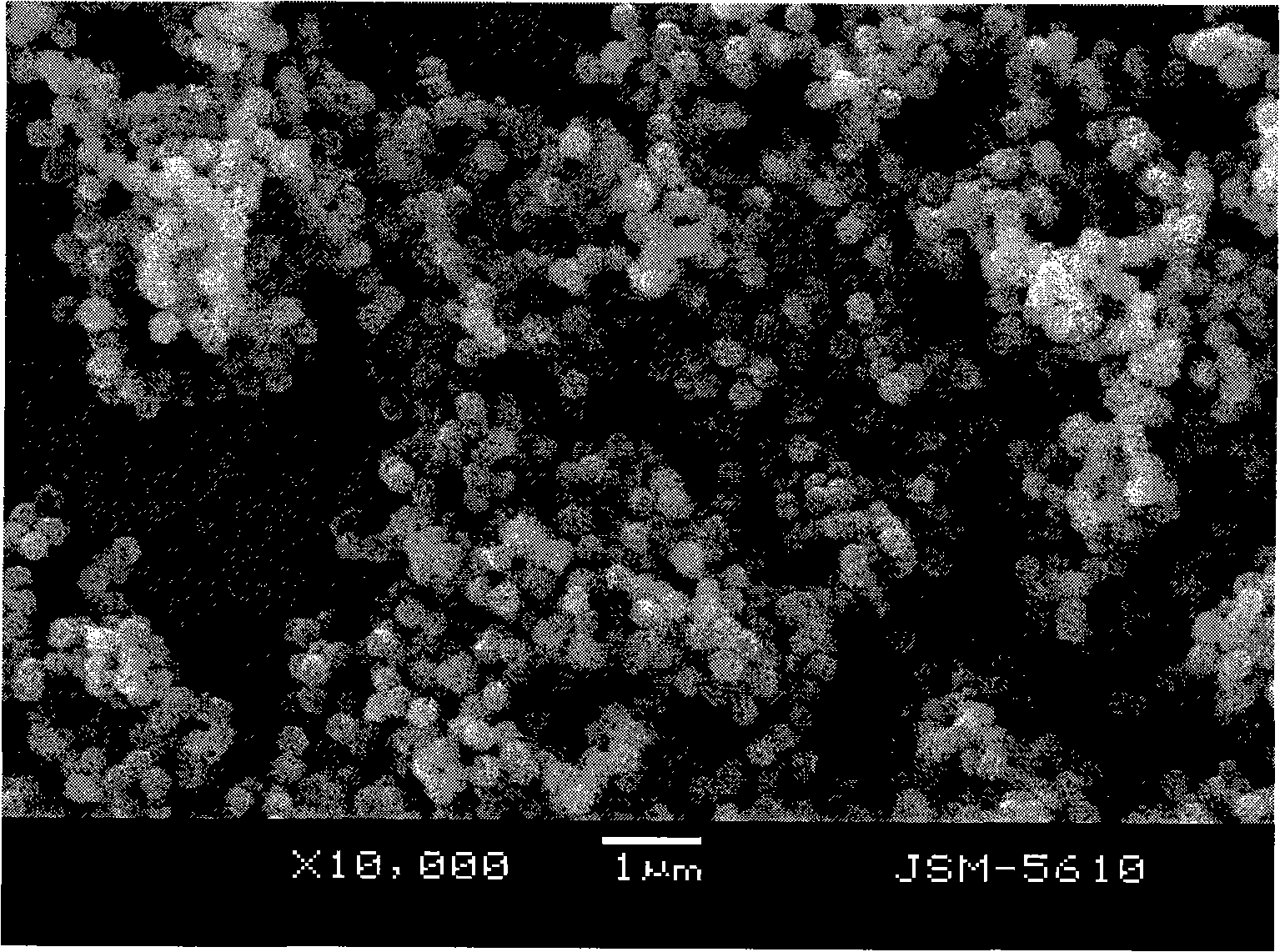

[0020] Dissolve 0.3677g of yttrium nitrate hexahydrate and 0.0178g of europium nitrate hexahydrate in 100mL of deionized water, and stir to obtain a uniform mixed solution. The total concentration of yttrium ions and europium ions is 0.01 mol / liter, wherein europium ions account for 4% of the total moles. %; 0.0618g boric acid is added in the mixed solution, stirred to make it dissolve completely; in the mixed solution, the ratio of the molar number of boric acid to the sum of the molar number of soluble yttrium salt and europium salt is equal to 1; 0.1800g urea is added to the above solution, Stir well to dissolve; a colorless and transparent solution is obtained. Put this transparent solution into a stainless steel autoclave lined with polytetrafluoroethylene, the volume of the liner is 120mL; the hydrothermal reaction temperature is controlled at 120°C, and the reaction time is 24h; the treated solution is centrifuged, dried, and then Obtained europium-doped yttrium borate ...

Embodiment 2

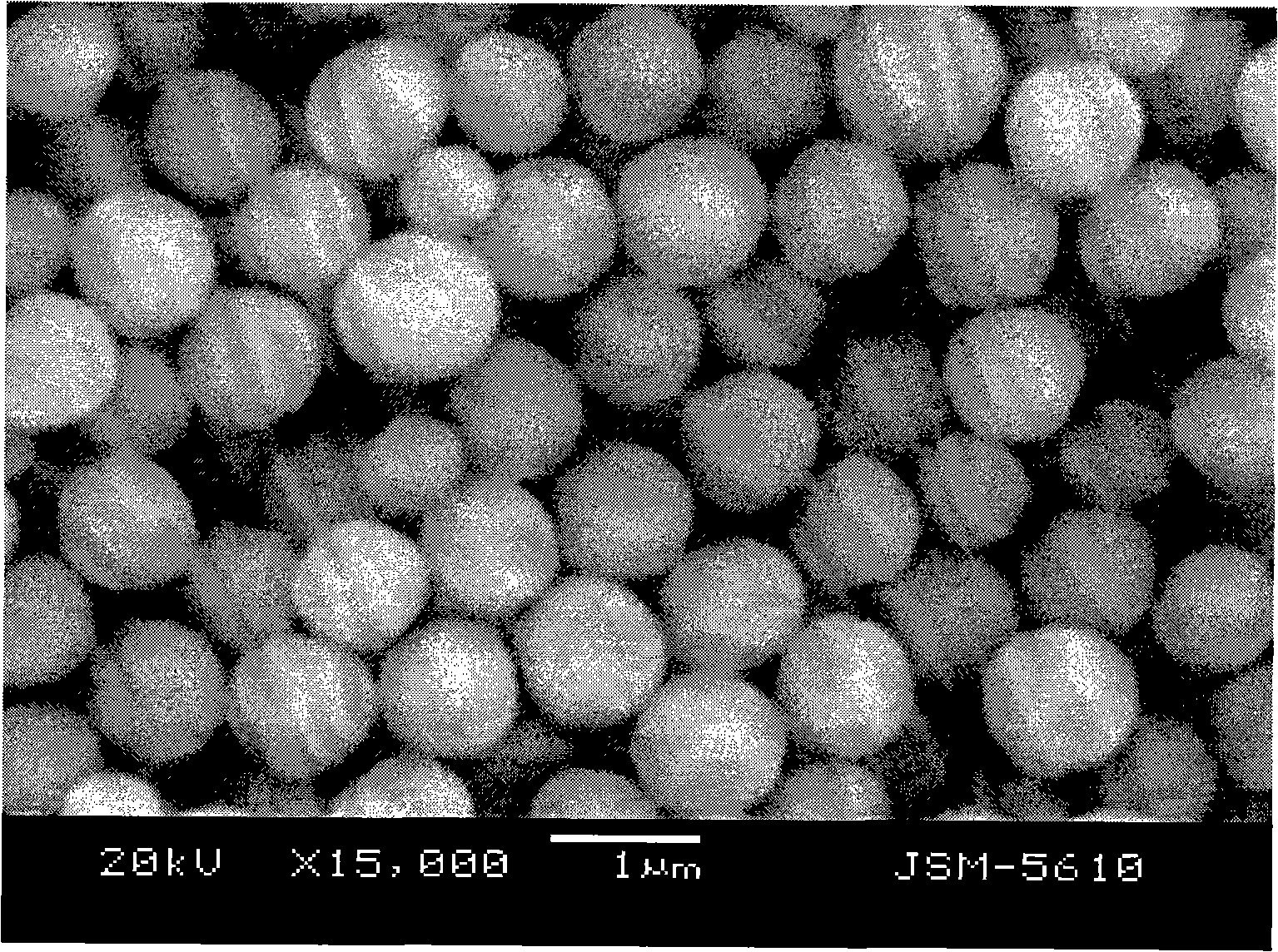

[0022] Dissolve 15.0161g of yttrium chloride hexahydrate and 0.1832g of europium chloride hexahydrate in 100mL of deionized water, and stir to obtain a uniform mixed solution. The total concentration of yttrium ions and europium ions is 0.5 mol / liter, of which europium ions account for the total number of moles Add 3.0915g of boric acid into the mixed solution and stir to dissolve it completely; in the mixed solution, the ratio of the moles of boric acid to the sum of the moles of soluble yttrium salt and europium salt is equal to 1; add 6.00g of urea to the above solution, stirred thoroughly to dissolve; a colorless and transparent solution was obtained. Put this transparent solution into a stainless steel autoclave lined with polytetrafluoroethylene, the volume of the liner is 120mL; the hydrothermal reaction temperature is controlled at 400°C, and the reaction time is 30min; the treated solution is centrifuged and dried, and then Obtained europium-doped yttrium borate spher...

Embodiment 3

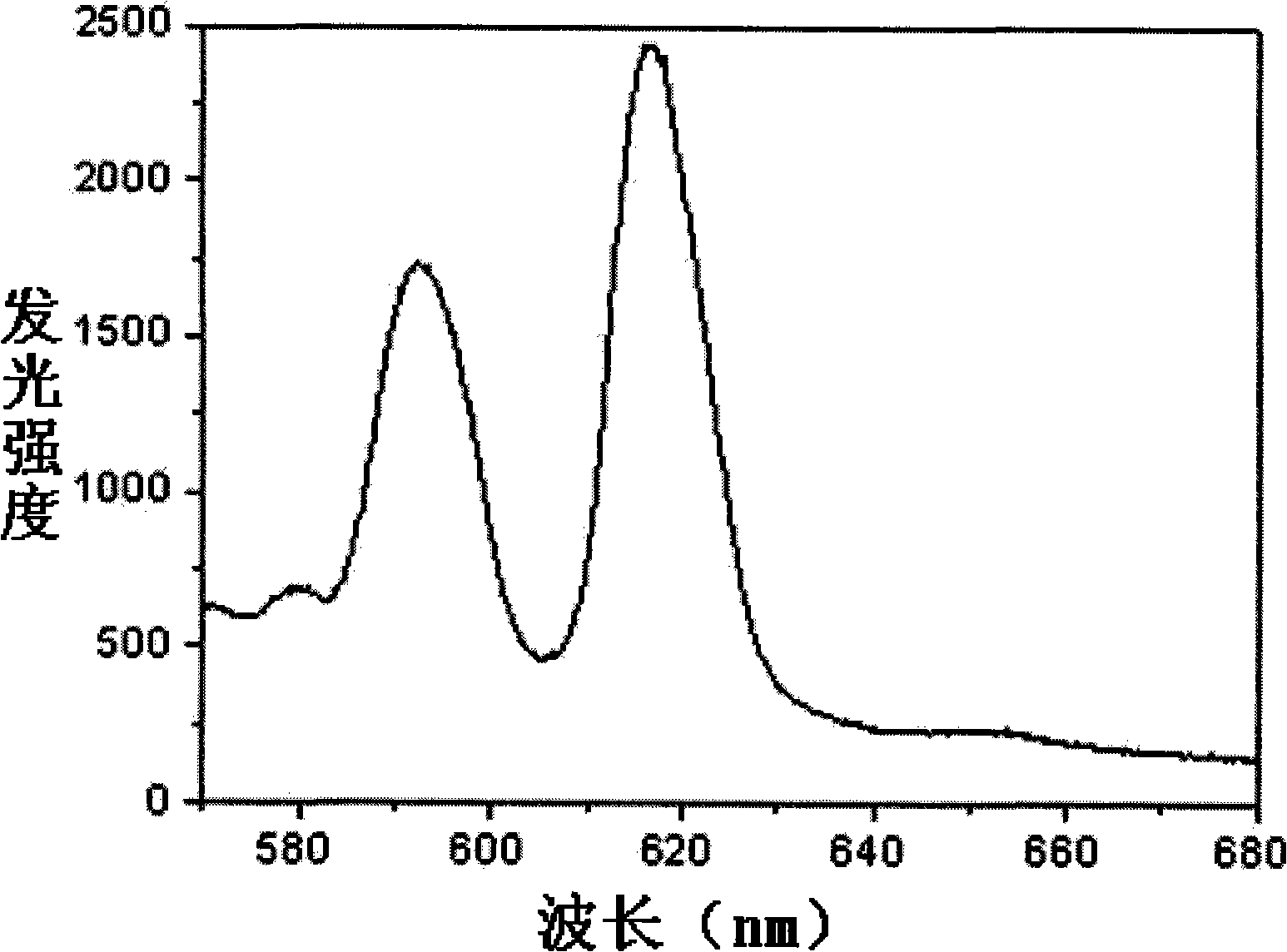

[0024] Dissolve 3.7918g of yttrium nitrate and 0.0446g of europium nitrate in 100mL of deionized water, stir to obtain a uniform mixed solution, the total concentration of yttrium ions and europium ions is 0.1 mol / liter, and wherein europium ions account for 1% of the total moles; 0.7420 Add 1g of boric acid into the mixed solution, stir to make it completely dissolved; in the mixed solution, the ratio of the moles of boric acid to the sum of the moles of soluble yttrium salt and europium salt is 1.2; add 1.80g of urea to the above solution, stir fully to make it Dissolved; a colorless and transparent solution was obtained. Put this transparent solution into a stainless steel autoclave lined with polytetrafluoroethylene, the volume of the liner is 120mL; the hydrothermal reaction temperature is controlled at 250°C, and the reaction time is 12h; the treated solution is centrifuged and dried, and then Obtained europium-doped yttrium borate spherical luminescent material: YBO 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com