Method for preparing primary titanium-rich material from high calcium-magnesium-titanium headings

A technology for titanium concentrates and titanium-rich materials, which is applied in the field of preparing primary titanium-rich materials from high permagnesium titanium concentrates, can solve problems such as difficult solutions, high technical difficulties, unreasonable economy, etc., and achieves fast heating speed and impurity acid. Good solubility and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

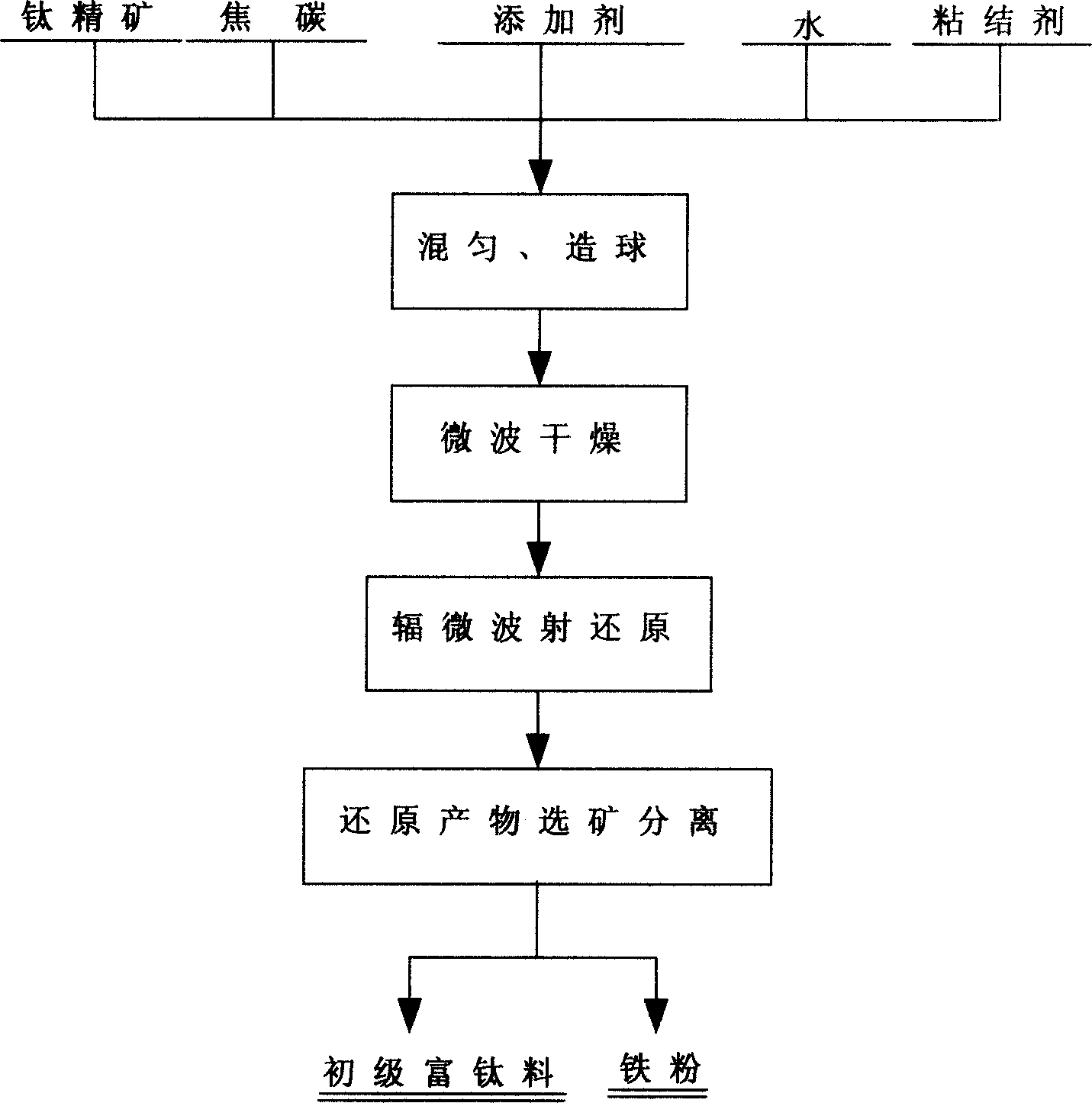

Method used

Image

Examples

Embodiment 1

[0012] The composition of titanium concentrate in a certain area of Panxi is TFe32.18%, TiO 2 48.84%, CaO1.56%, MgO5.56%, SiO 2 5.6%, grinding to a particle size of less than 0.074mm accounts for 60% by weight, adding 16% water, 5% binder sodium silicate, 10% coke, 2% additive sodium sulfate, 3% additive Iron powder and 3% additive potassium chloride are used to make composite pellets with a diameter of 10-15mm; the pellets are dried by microwave, the power of microwave drying is 750W, the drying temperature is 200°C, and the drying time is 12min. The content is less than 5% by weight; the microwave-dried pellets are placed in a microwave oven for reduction, and the extra coke accounts for 40% of the weight of the titanium concentrate; the reduction temperature of the pellets is 1150 ° C; the reduction time is 90 minutes; the reduced pellets Wet ball milling is carried out until the ore particle size is 0.074mm and the weight accounts for 70%. Iron powder and non-magnetic m...

Embodiment 2

[0014] The composition of titanium concentrate in a certain area of Panxi is Tfe34.18%, TiO 2 46.42%, CaO2.28%, MgO5.86%, SiO 2 4.6%, grinding until the particle size is less than 0.074mm accounts for 80% by weight, adding 20% water, 3% sodium silicate, 18% coke, 4% sodium sulfate, 1% iron powder, 5 % Potassium Chloride to make composite pellets with a diameter of 10-15mm; the pellets are microwave-dried, the microwave drying power is 1000W, the drying temperature is 300°C, and the drying time is 3min, and the microwave-dried pellets are placed in a microwave oven Reduction, adding coke accounts for 60% of the weight of the titanium concentrate, the reduction temperature of the pellets is 1120°C, and the reduction time is 120min. After reduction, the pellets are subjected to wet ball milling until the particle size is 0.074mm, accounting for 85% by weight. After magnetic separation Iron powder and non-magnetic matter are obtained by separation, and the non-magnetic matter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com