Method for determining rod diameter of rod mill

A technology of rod mill and rod diameter, which is applied in the field of fine grinding and ore crushing, can solve problems such as inappropriateness, and achieve the effect of heavy workload and simple and convenient determination method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

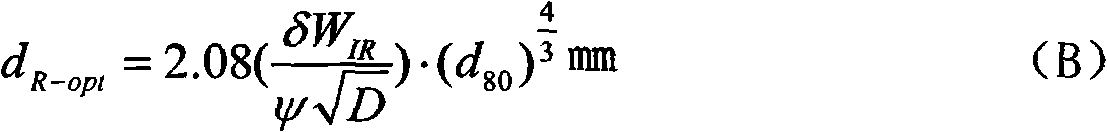

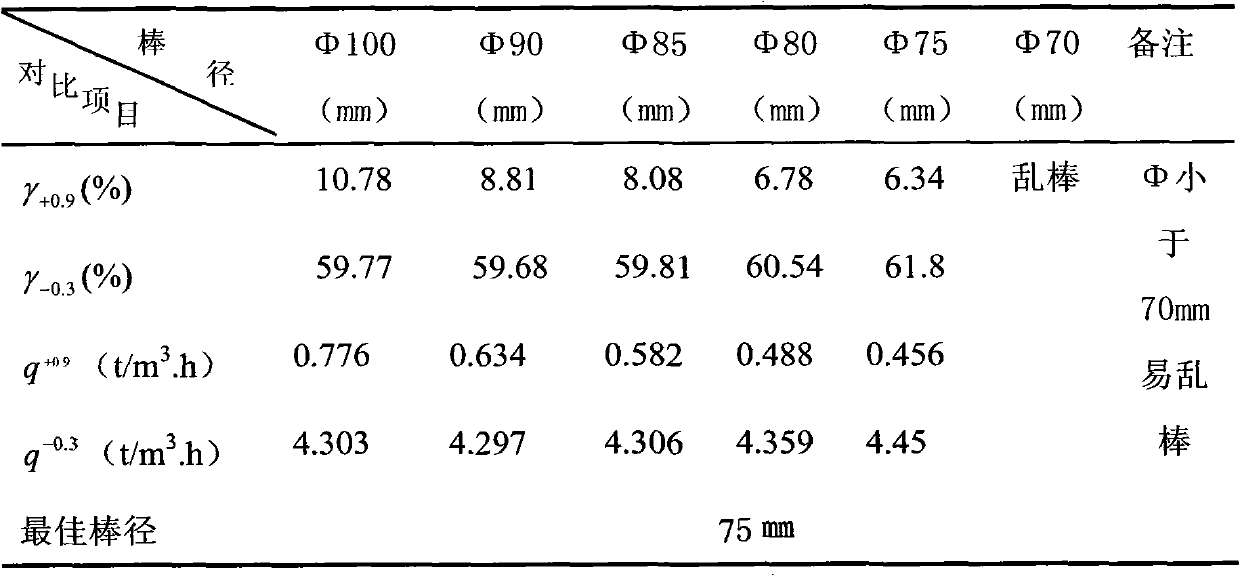

Method used

Image

Examples

Embodiment Construction

[0042] Examples are carried out according to the steps described in the Summary of the Invention. details as follows:

[0043] The ore processed by the No. 2 Alumina Plant of Chalco Henan Branch is bauxite, and the rough mill is D×L3.6×5.0m rod mill, the rotation rate ψ=65%, the filling rate Ore specific gravity 2.95g / cm 3 , pulp concentration C = 75%. Calculate the maximum rod diameter under this grinding condition.

[0044] ① The measured uniaxial compressive strength of the ore σ = 1028.89kg / cm 2 , elastic modulus E=5.268×10 5 kg / cm 2 , Poisson's ratio μ = 0.225, for medium-hard, brittle ore.

[0045] ②Sieve the feed ore of the rod mill for particle size analysis, and calculate the maximum particle size d′ for 95% of the sieve f 40mm, the average particle size

[0046]③Convert the actual working conditions of the rod mill to the calculated D×L3.6×5.0m ball mill, the rotation rate ψ=65%, the filling rate Ore specific gravity 2.95g / cm 3 , σ 压 =1028.89kg / cm 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com