Automatic steel ball sorting machine

An automatic sorting and steel ball technology, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of unqualified steel balls mixed in, refiner damage, etc., to increase the drop height, reduce the drop height, Avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

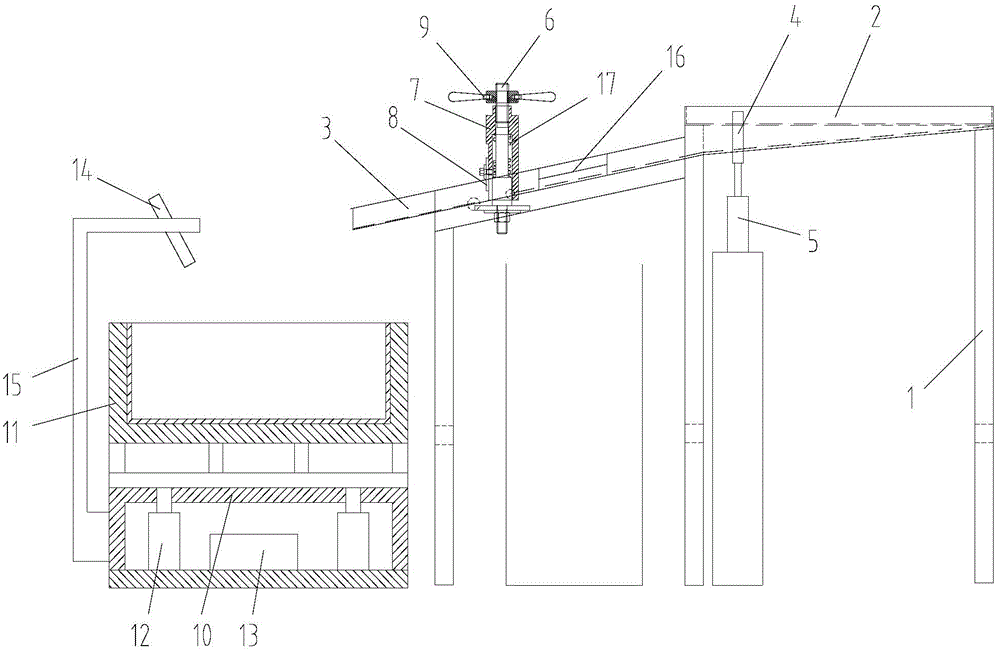

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] As shown in the figure, the steel ball automatic sorting machine of this embodiment includes a frame 1, and the frame is provided with a ball storage tank 2, a telescopic material door device arranged at the outlet of the ball storage tank, and a ball storage tank. The inclined sorting tank 3 connected to the outlet of the tank, the knife ruler assembly arranged on the sorting tank, and the qualified ball receiving device arranged at the lower part of the outlet of the sorting tank, the bottom surface of the ball storage tank is an inclined surface;

[0018] The telescopic material door device includes a material door 4 horizontally arranged at the bottom of the ball storage tank and a lifting cylinder 5 that drives the material door to move up and down, and the material door and the bottom of the tank body slide up and down;

[0019] The sorting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com