Method for fixing electric pole

A fixing method and pole technology, which is applied in the field of poles, can solve the problems that poles cannot be recycled and used, and achieve the effects of reducing compensation, strong compression resistance, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

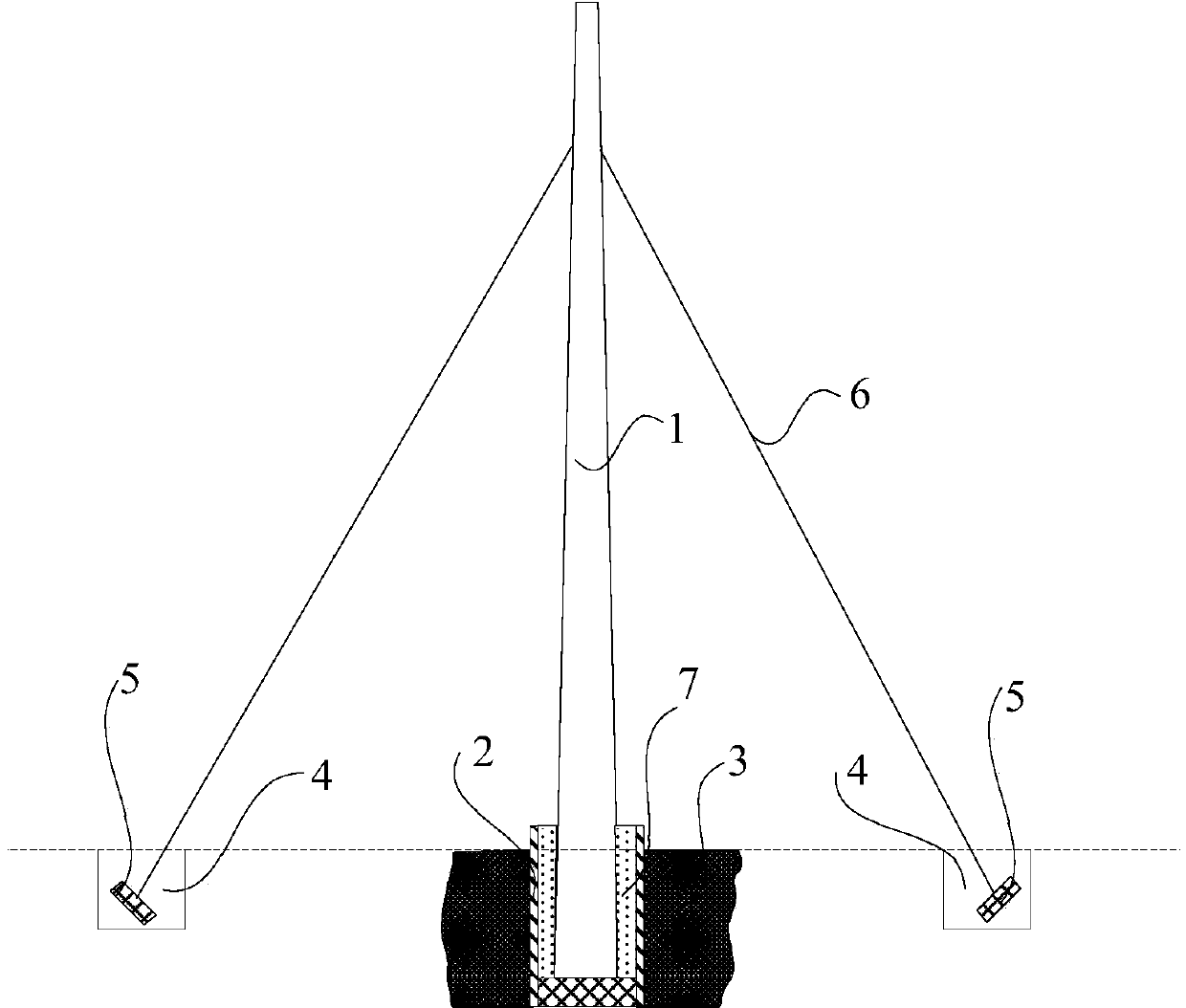

[0049] A kind of fixing method of electric pole 1, prepare electric pole 1 and fixing sleeve 2 that are made of polyurethane material, wherein electric pole 1 is tapered electric pole 1, and length is 12 meters, and the taper of electric pole 1 is 1: 50; the axial length of the fixed sleeve 2 is 1 / 6 of the length of the electric pole 1, that is, the length of the fixed sleeve 2 is 2 meters, and the depth of the electric pole foundation pit 3 is also 2 meters. Place the fixing sleeve 2 in the electric pole foundation pit 3, and fill concrete between the outer wall of the fixing sleeve 2 and the electric pole foundation pit 3, and fill the bottom of the fixing sleeve 2 with concrete or soil tamping; put one end of the pole 1 into the fixed sleeve 2 paved with concrete or soil, and the distance between the inner side wall of the fixed sleeve 2 and the outer wall of the pole 1 is 5 cm, and Fill filler 7 in the gap of this 5 centimeters so that pole 1 is fixed, described filler 7 i...

Embodiment 2

[0051] A method for fixing an electric pole 1, prepare an electric pole 1 and a fixing sleeve 2 made of polyurethane material, wherein the electric pole 1 is a tapered electric pole 1, the length is 12.5 meters, and the taper of the electric pole 1 is 1: 75; the axial length of the fixed sleeve 2 is 1 / 5 of the length of the electric pole 1, that is, the length of the fixed sleeve 2 is 2.5 meters, and the depth of the electric pole foundation pit 3 is also 2.5 meters. Place the fixing sleeve 2 in the electric pole foundation pit 3, and fill concrete between the outer wall of the fixing sleeve 2 and the electric pole foundation pit 3, and fill the bottom of the fixing sleeve 2 with concrete or soil tamping; put one end of the pole 1 into the fixed sleeve 2 paved with concrete or soil, and the distance between the inner side wall of the fixed sleeve 2 and the outer wall of the pole 1 is 8 cm, and Fill filler 7 in this 8 centimeter gap so that pole 1 is fixed, described filler 7 i...

Embodiment 3

[0053] A kind of fixing method of electric pole 1, prepare electric pole 1 and fixing sleeve 2 that are made of polyurethane material, wherein electric pole 1 is tapered electric pole 1, and length is 16 meters, and the taper of electric pole 1 is 1: 50; the axial length of the fixed sleeve 2 is 1 / 4 of the length of the electric pole 1, that is, the length of the fixed sleeve 2 is 4 meters, and the depth of the electric pole foundation pit 3 is also 4 meters. Place the fixing sleeve 2 in the electric pole foundation pit 3, and fill concrete between the outer wall of the fixing sleeve 2 and the electric pole foundation pit 3, and fill the bottom of the fixing sleeve 2 with concrete or soil tamping; put one end of the pole 1 into the fixed sleeve 2 paved with concrete or soil, and the distance between the inner side wall of the fixed sleeve 2 and the outer wall of the pole 1 is 10 cm, and In this 10 centimeter gap, fill filler 7 so that pole 1 is fixed, and described filler 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com