Novel vortex generator for wind turbine blade

A technology of vortex generators and wind turbine blades, which is applied in the directions of wind power generators, wind power generation, and wind power engines in the same direction as the wind. The structure is weak and other problems, to achieve the effect of suppressing the three-dimensional flow of the blade root, the shape resistance is small, and the three-dimensional flow is suppressed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below through specific embodiments with reference to the accompanying drawings. These embodiments are only used to illustrate the present invention and do not limit the protection scope of the present invention.

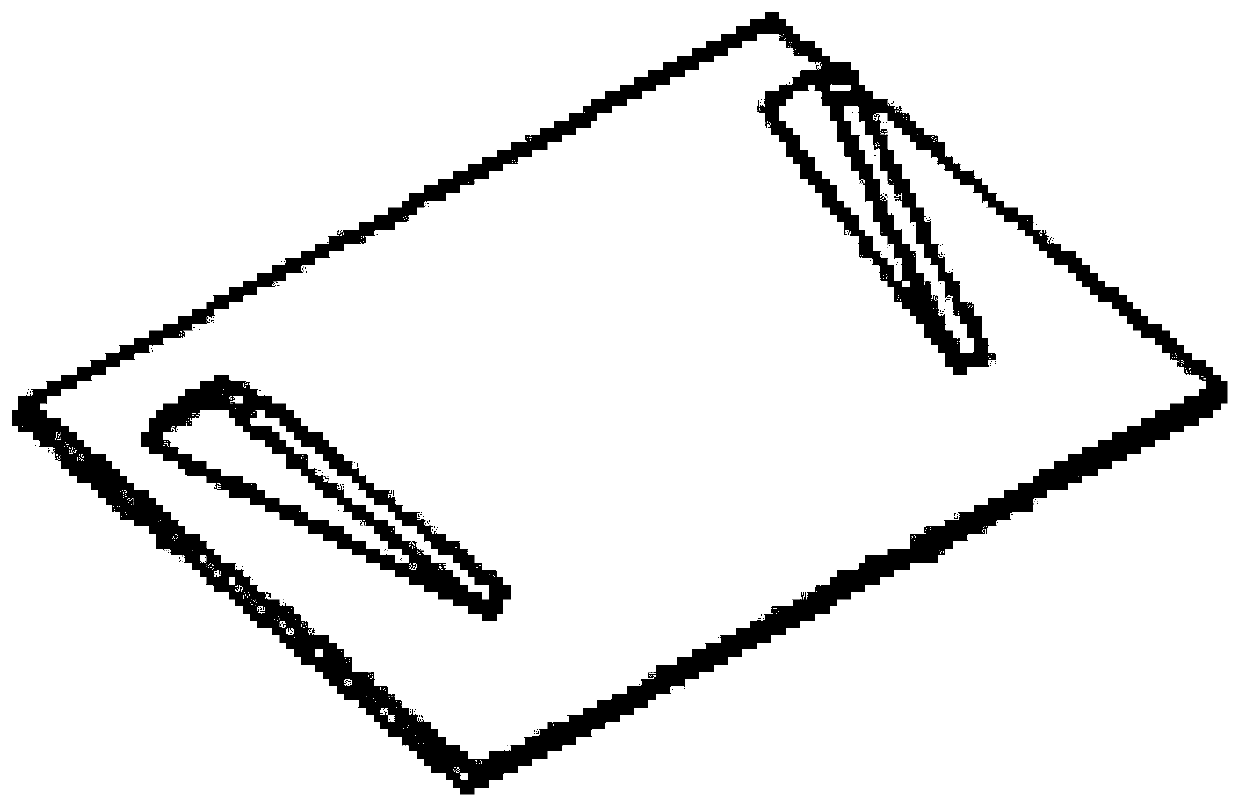

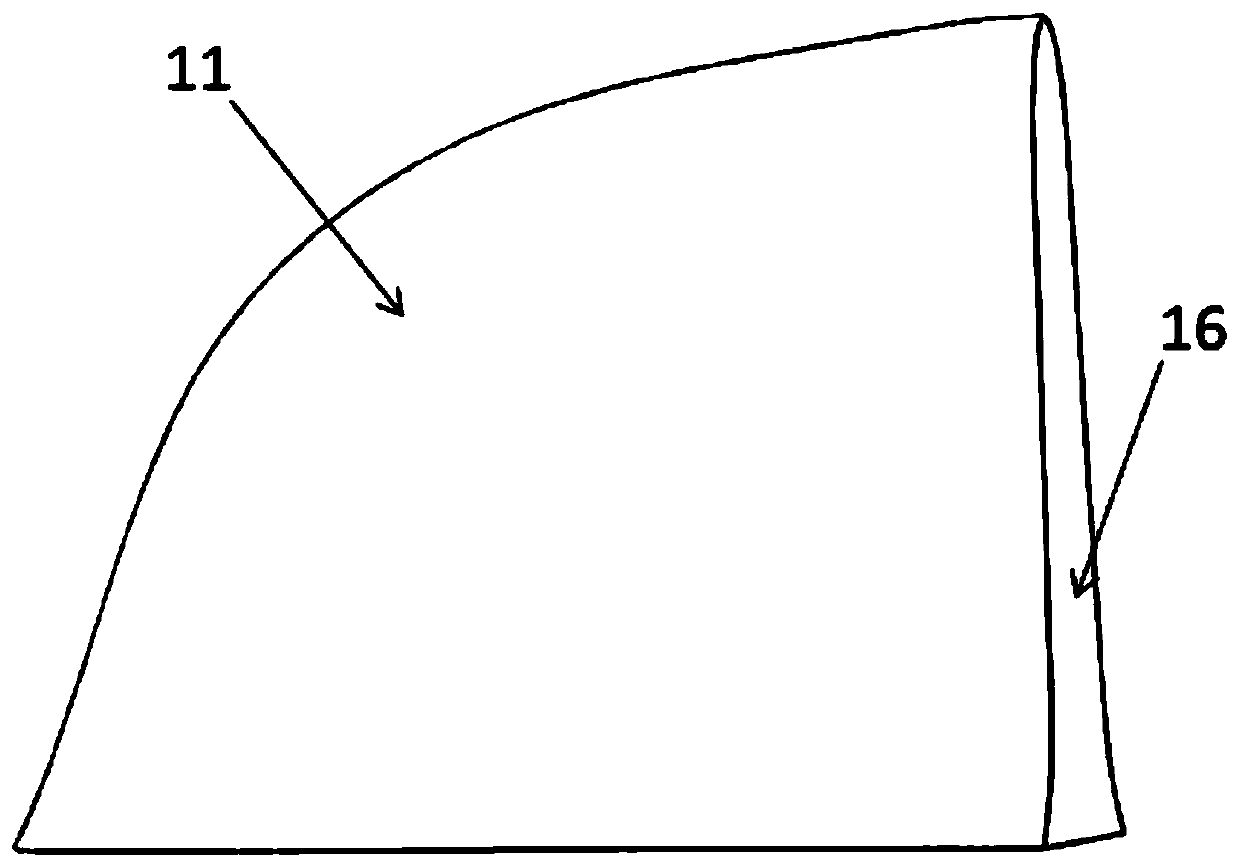

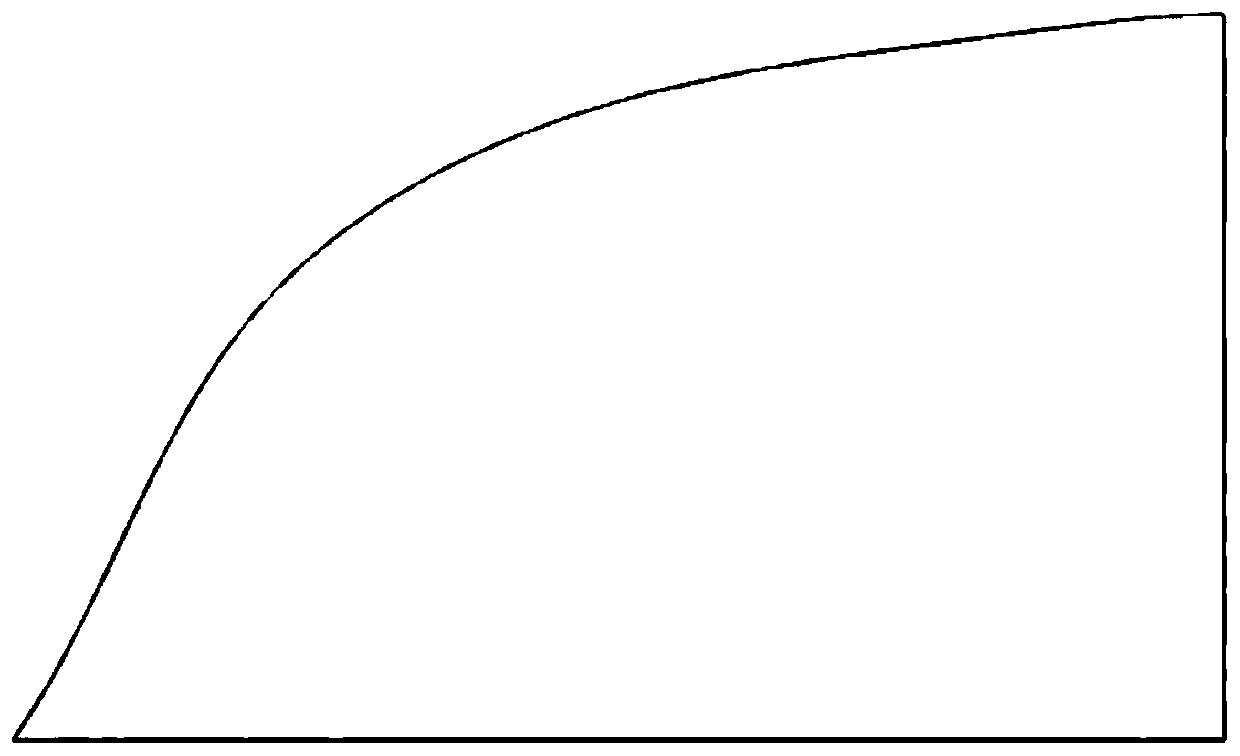

[0031] Such as figure 2 with image 3 As shown, the present invention provides a novel vortex generator 10 for a wind turbine blade 20, which includes a fin body 11; the fin body 11 is a dorsal fin structure and is symmetrical with respect to its middle longitudinal section 12; The middle longitudinal section 12 is parallel to the flow direction of the leading edge 23 to the trailing edge 24 of the wind turbine blade airfoil section 26 where the vortex generator 10 is located, so as to reduce the projected area of the fin body 11 perpendicular to the air flow direction , Thereby reducing the shape resistance.

[0032] Such as Figure 4 As shown, in one embodiment, the fin body 11 includes a bottom surface 13 and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com