Control plane cavitation effect suppression device

A cavitation effect and suppressing device technology, applied in the field of ship rudder, can solve problems such as increased resistance and damage, and achieve the effects of increasing the critical Reynolds number, extending the laminar flow area, and reducing the separation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples describe the present invention in more detail.

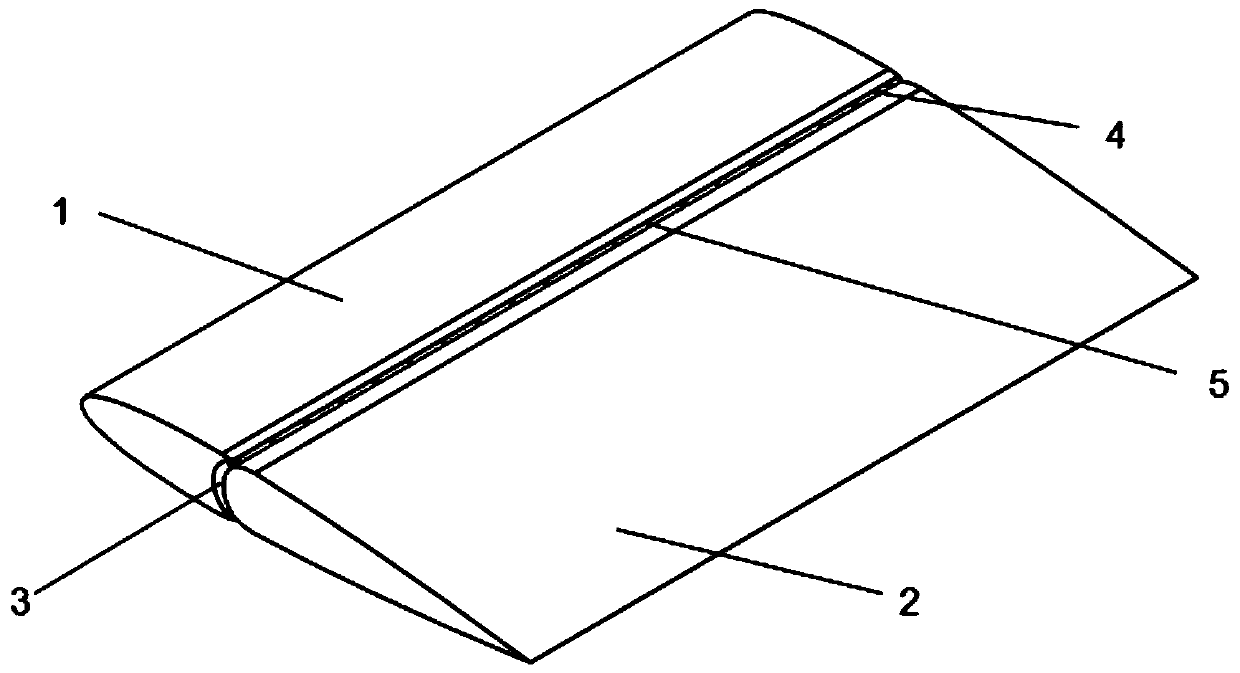

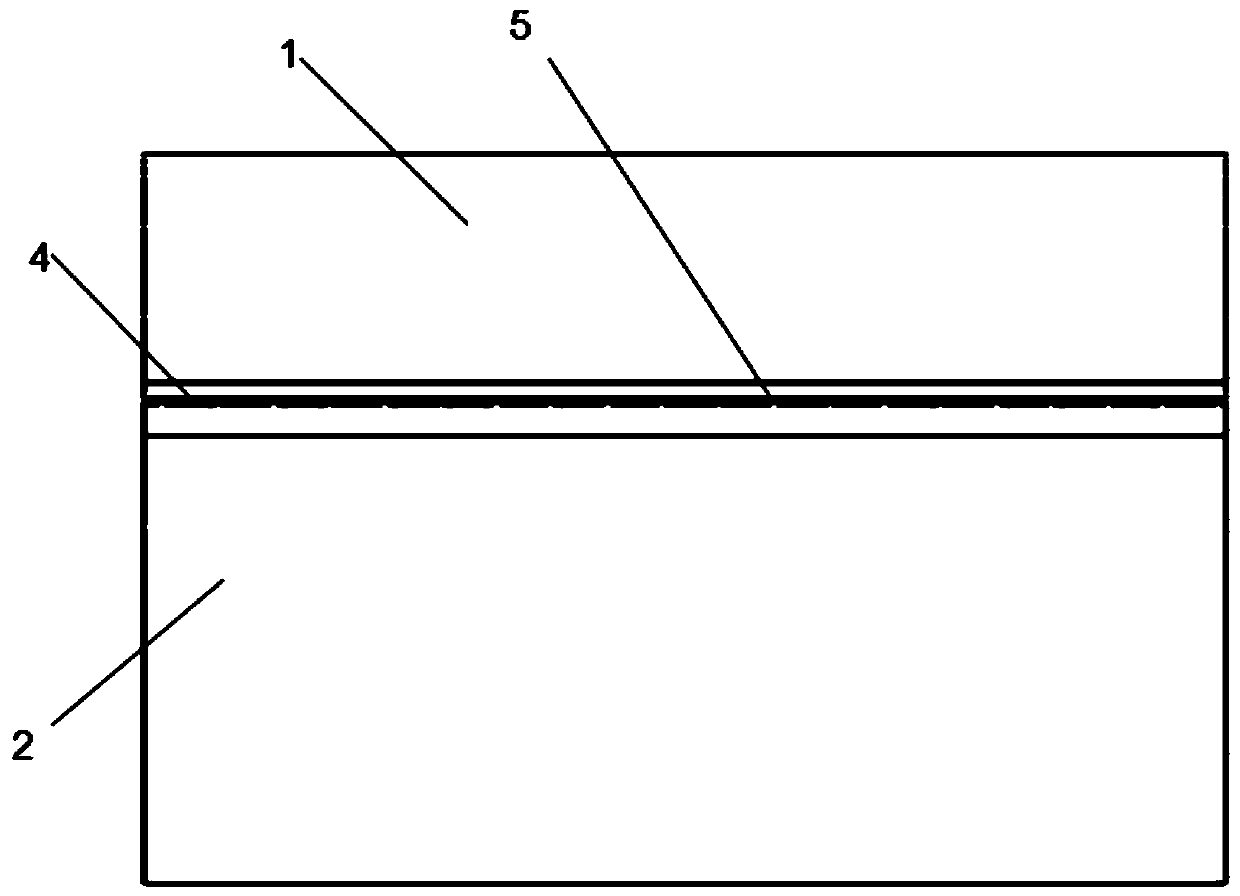

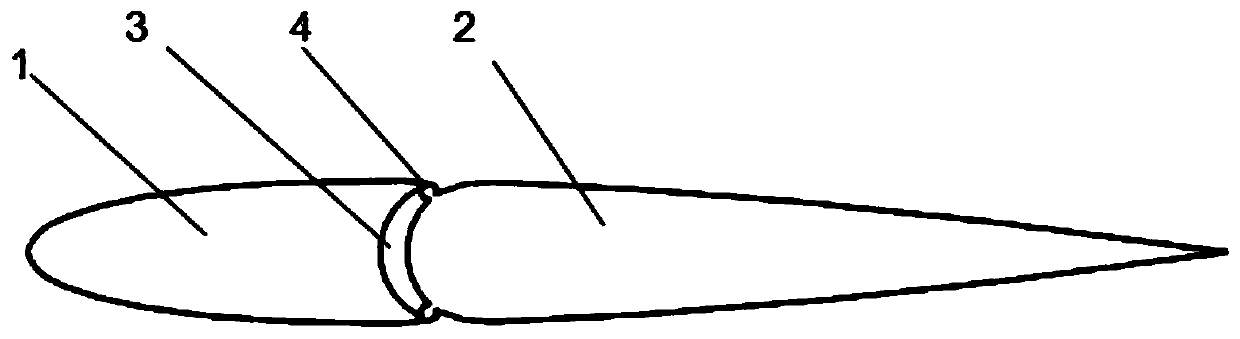

[0024] combine Figure 1 to Figure 6 The rudder surface cavitation suppression device of the present invention comprises an air pump 7 and a vent pipe 4, the air pump is installed inside the hull, the vent pipe is positioned at the gap between the rudder arm and the rudder blade, and the upper end of the vent pipe is fixed on the stern board 8 And communicate with the air pump, the lower end of the ventilation pipe is closed. The rudder arm 1 is connected to the rudder blade 2 and the rudder blade 2 can be rotated. The air pipe 4 is located in the gap 3 between the rudder arm 1 and the rudder blade 2. The two air pipes 4 are placed symmetrically with respect to the chord length, and the air holes 5 are evenly distributed in the air vents. On the trachea 4, the air holes 5 are distributed along the length and blow air to the rudder surface. The air pump 7 is located above the stern plate 8. The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com