Prerotation fan-shaped conduit for right-handed single-screw ship

A fan-shaped and duct-shaped technology, which is applied in the direction of rotating propellers and rotary propellers, can solve the problems of low propulsion efficiency of the propeller, uneven follow-up flow, fatigue, etc., and achieve the goal of reducing the wet surface area, stabilizing the structure, and strengthening the pre-rotation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

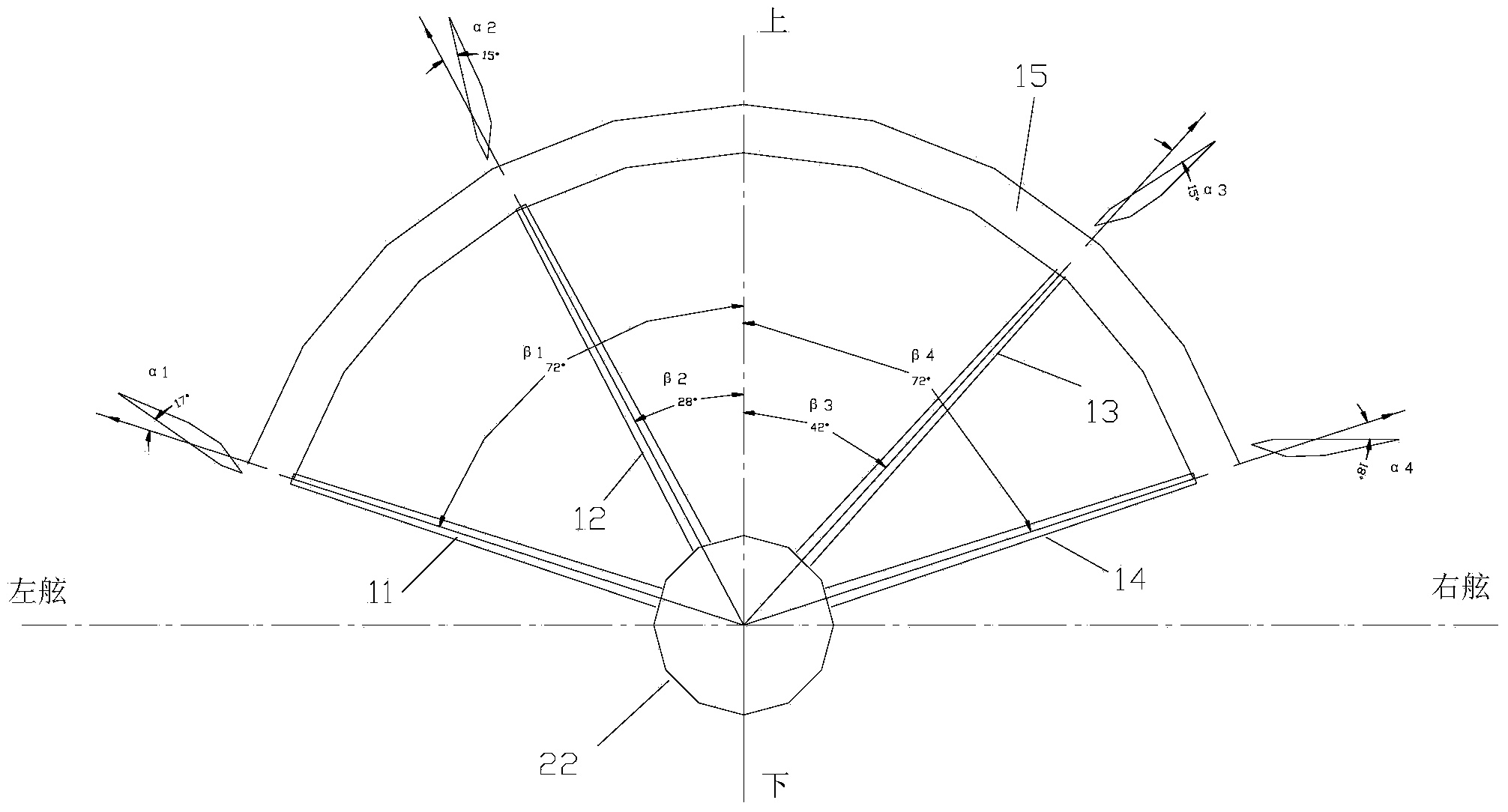

[0029] According to the characteristics of hull follow current calculated by CFD or measured by ship model test and the direction of propeller rotation, a pre-swirl triangular duct with completely asymmetric arrangement in front of the propeller installed at the stern of a medium-low speed ship is invented to improve the propulsion efficiency and evenly accompany the propeller. flow, reducing the risk of hull vibration.

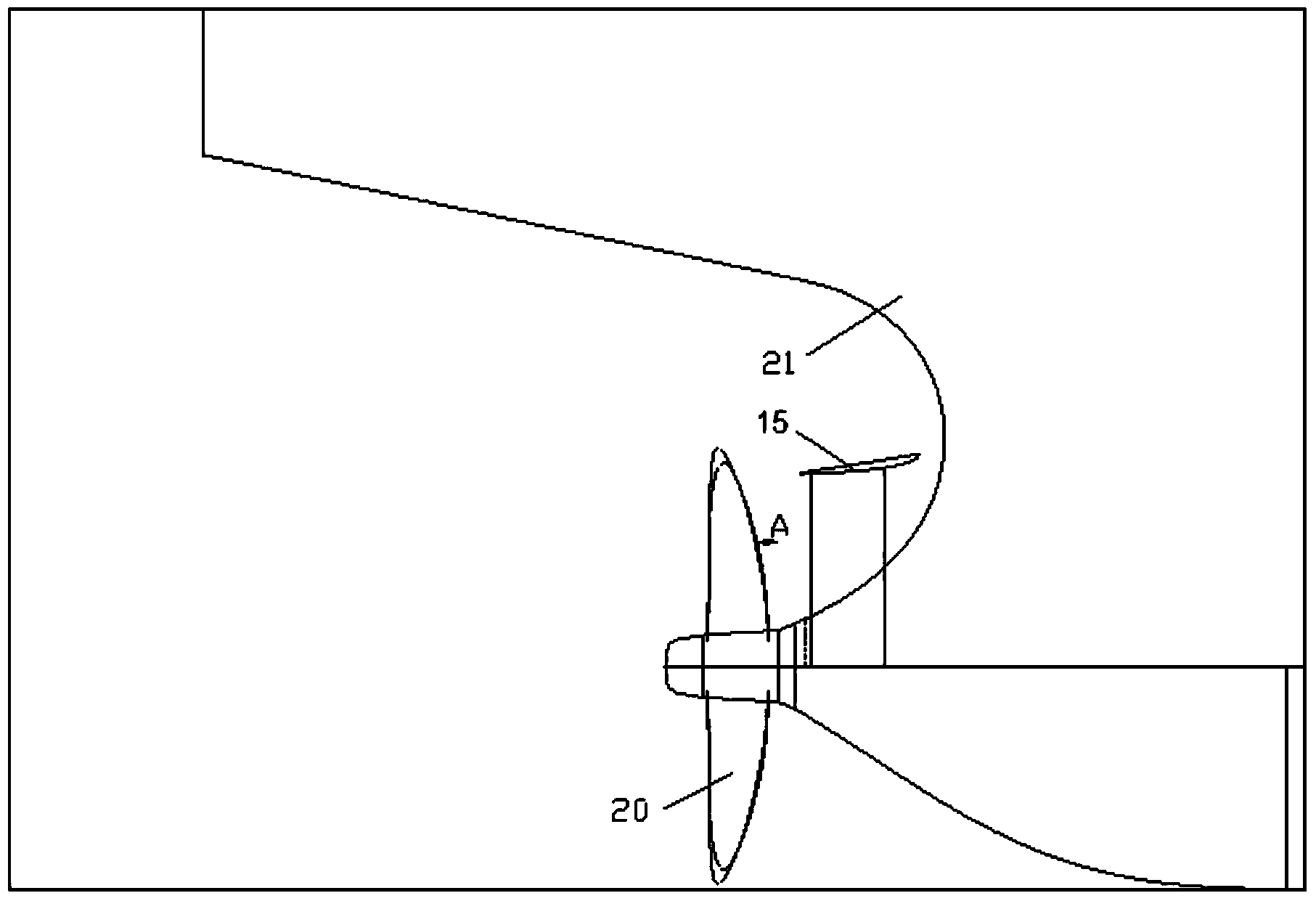

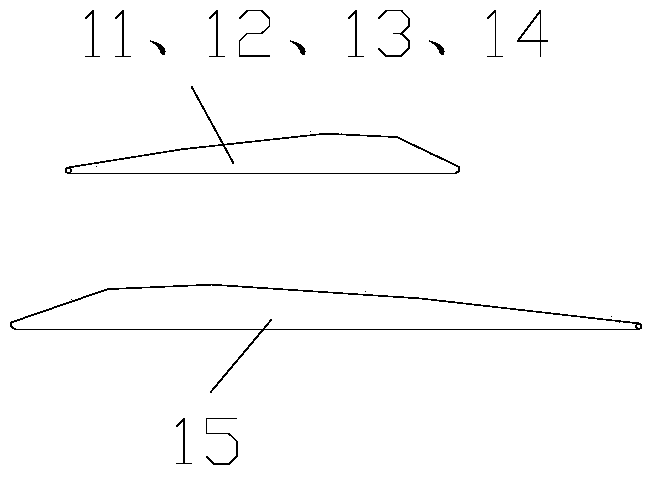

[0030] like figure 1 , figure 2 The shown pre-rotating fan-shaped duct for a right-handed single-screw ship is located between the propeller 20 at the stern and the hull 21. Viewed from the rear side of the propeller 20, the stern on the left side of the propeller hub longitudinal centerline is from top to bottom. The second blade 12 and the first blade 11 are arranged below, and the stern on the right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com