Pumping chamber for shaft seal type nuclear main pump

A nuclear main pump and pressurized water chamber technology, applied in the direction of non-variable pumps, pumps, pump components, etc., can solve the tight installation space, high pressure bearing performance requirements of the pump casing, and the spiral volute can not meet the pressure bearing requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

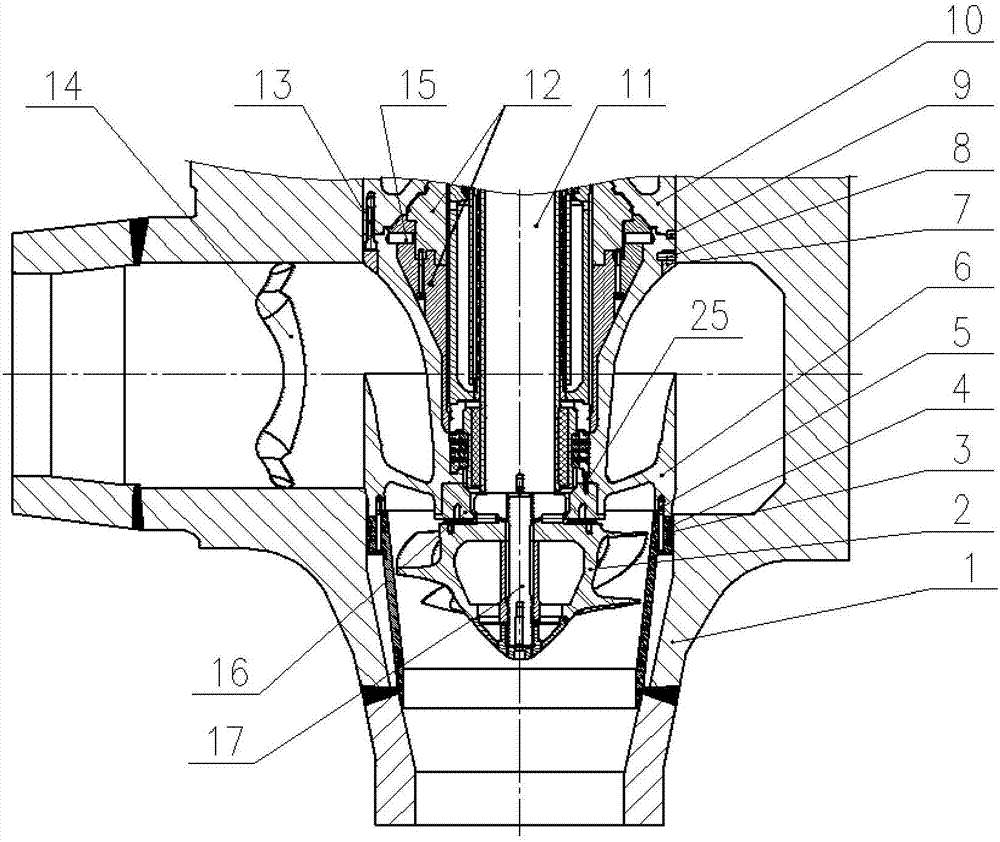

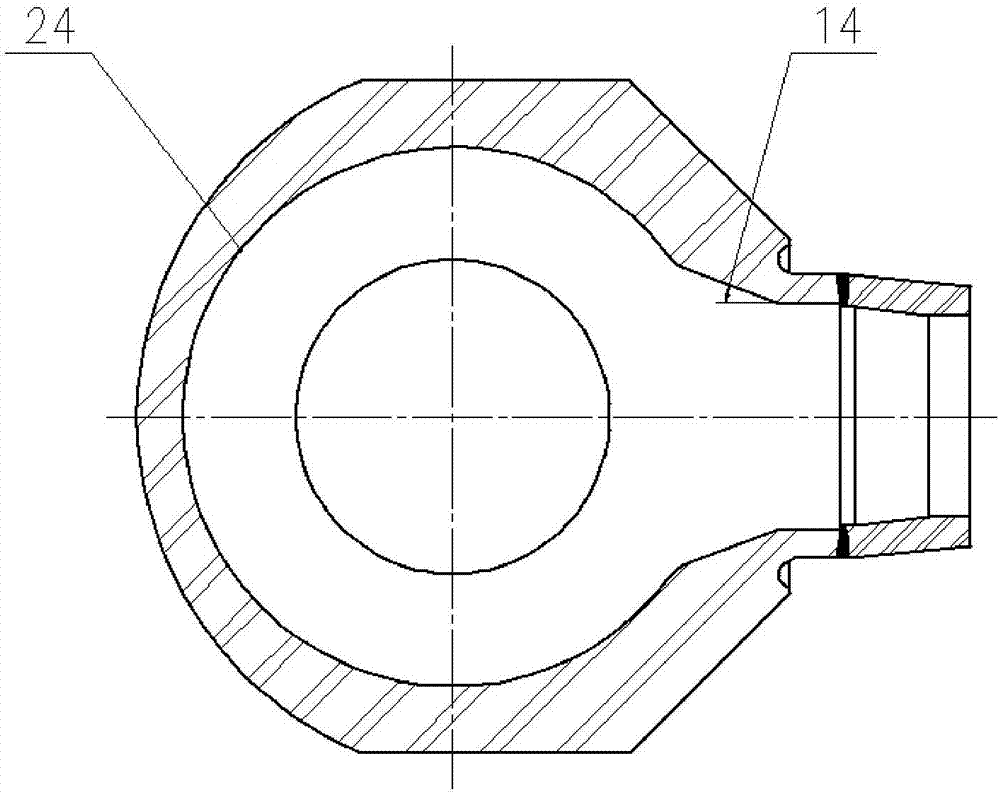

[0013] Such as figure 1 In the pressurized water chamber of a shaft-sealed nuclear main pump shown, the inlet of the vane body 6 is connected to the shroud 3 through a plurality of circumferentially evenly distributed bolts 5, and the shroud 3 is sealed with the pump casing 1 by double seal rings 4. , the inside of the shroud 3 is the impeller 2, the impeller 2 is connected to the pump shaft 11 through the bolt 17; the guide vane body 6 is formed by uniformly distributing a plurality of guide vanes 20 with equal axial flow sections; Uniformly distributed bolts 13 are connected to the sealing chamber 10, and the guide vane body 6 and the sealing chamber 10 realize precise positioning under multiple working conditions through two radial positioning pins 9.

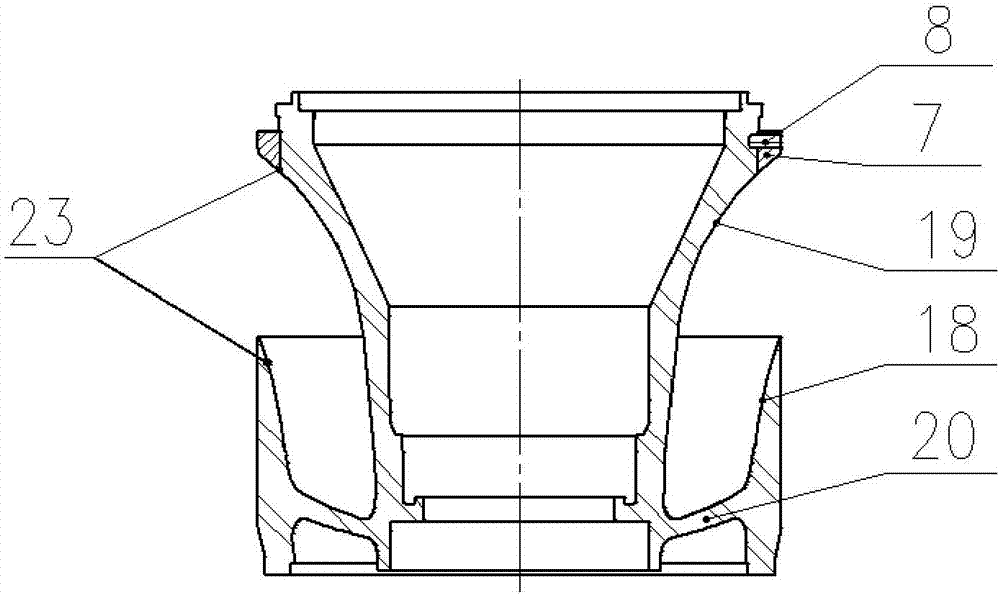

[0014] Such as figure 2 As shown, the guide vane 20 is fixed between the outer edge inner wall 18 and the inner edge outer wall 19, the cone angle at the entrance of the guide vane body 6 is 5.25°, and the cone angle at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contraction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com