Elliptical tube H-shaped fin heat exchanger for waste heat recovery

A finned heat exchanger and waste heat recovery technology, which is applied in heat exchange equipment, tubular elements, lighting and heating equipment, etc., can solve the problem that the convective heat transfer coefficient of straight fins is not high and cannot meet the requirements of large heat transfer , pressure drop loss, dust accumulation in the wake area, etc., to achieve the effect of improving heat transfer coefficient, reducing fouling, and increasing fluid disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

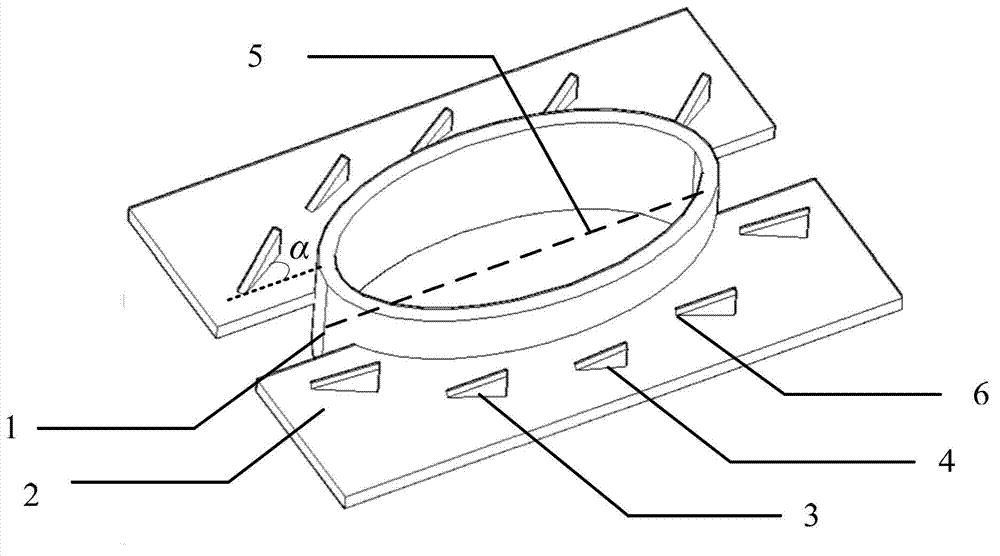

[0012] see figure 1 , the present invention includes elliptical heat exchange tubes 1 and several groups of H-shaped substrates 2 set on the elliptical heat exchange tubes 1, the long axis 5 of the elliptical heat exchange tubes 1 is arranged along the mainstream direction, and the ratio of the long and short axes is 1.88; The H-shaped fins 2 are rectangular fins, and the aspect ratio of the rectangular fins is 1.42; on the H-shaped fins 2, two groups of triangular winglets 3 are symmetrically punched out or welded around the oval heat exchange tube 1, and each triangular winglet 3 is a right-angled structure with a chord-to-height ratio of 2. Each set of triangular winglets is composed of five triangular winglets. From the front and rear ends of the H-shaped fin to the middle of the H-shaped fin, the angle of attack of the triangular winglet decreases succe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com