Patents

Literature

37results about How to "Improve dust accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elliptical tube H-shaped fin heat exchanger for waste heat recovery

ActiveCN103438746AIncrease disturbanceIncrease the thermal resistance of heat transfer, reduce the wake zone" enhanced heat transfer principleTubular elementsParticle adhesionWaste heat recovery unit

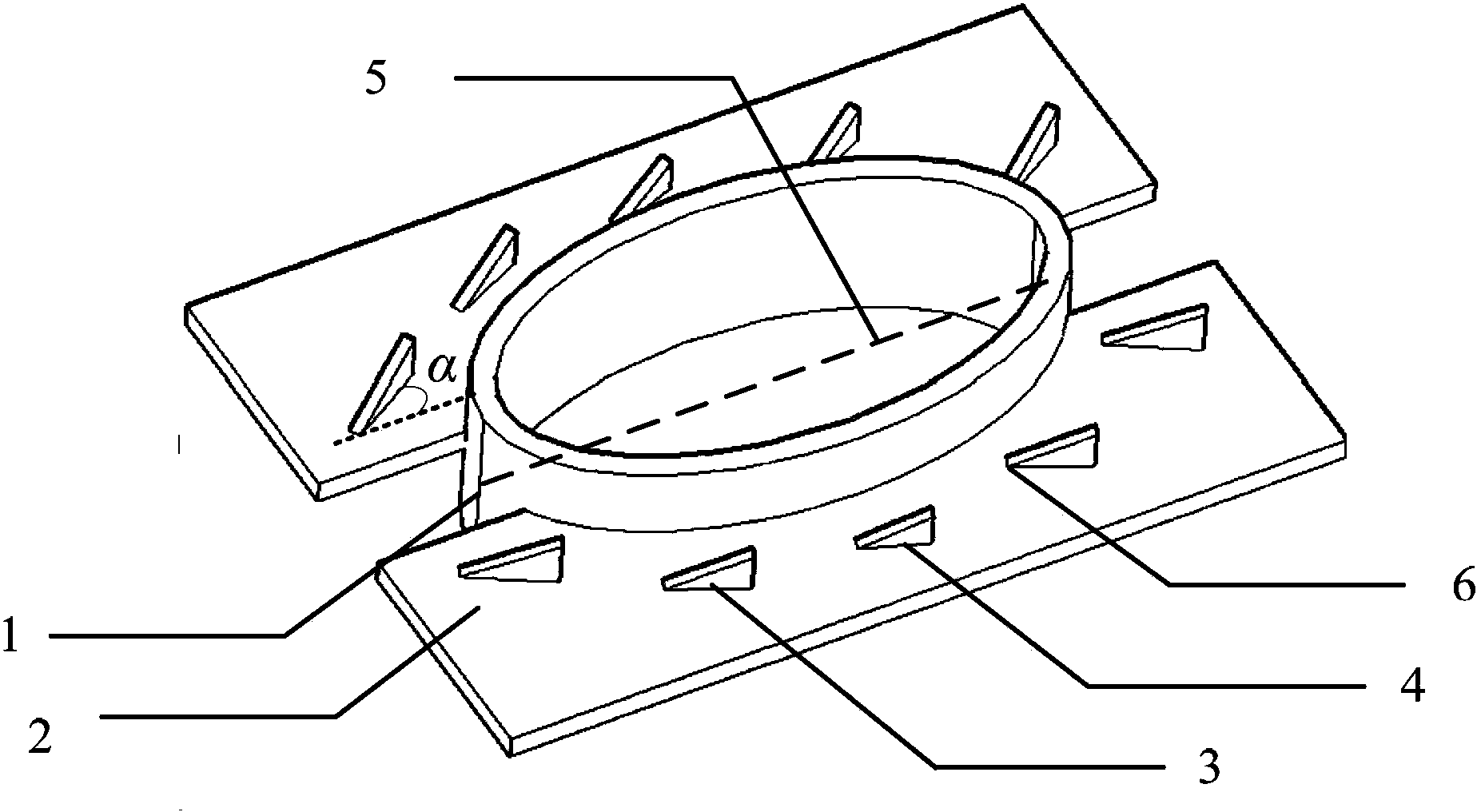

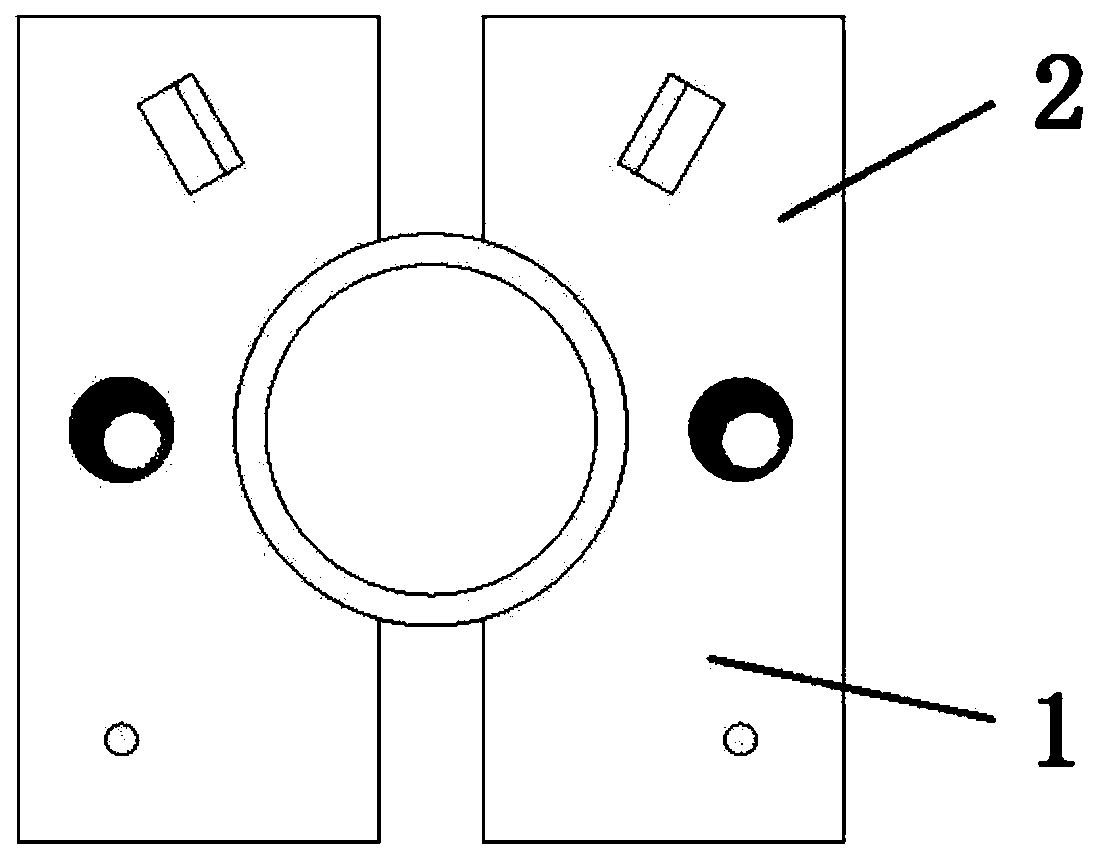

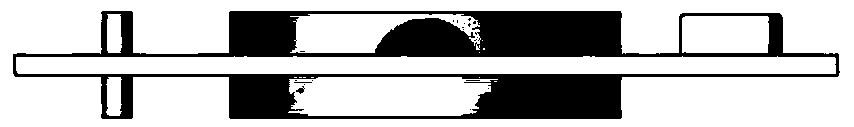

The invention discloses an elliptical tube H-shaped fin heat exchanger for waste heat recovery. The elliptical tube H-shaped fin heat exchanger comprises an elliptical heat exchange tube, a plurality of groups of H-shaped fins and a heat exchanger surface, wherein the H-shaped fins are sleeved on the surface of the heat exchange tube; the heat exchanger surface consists of non-uniform triangular small wings, which are elliptically arranged, on the surfaces of the H-shaped fins around the elliptical heat exchange tube. When dusty flue gas flows through the surfaces of the H-shaped fins, the small wings disturb the fluid to enhance the heat exchange on the tube wall and the downstream side, and meanwhile, the deposition of particles on the tube wall is reduced; the pressure drop can be reduced by the elliptical tube while the particle adhesion is reduced. A plurality of longitudinal vortexes are arranged in a non-uniform manner; at the front and rear edges of the wing, the size of the small wings and the windward attack angle are larger; on the middle parts of the H-shaped fins, the size of the small wings and the attack angle are smaller; by using the device, the heat exchange surface in different flow states can be enhanced respectively, the heat exchange of the fins are effectively enhanced, the pressure drop is reduced, and the deposition of dust particles in the flue gas on the heat exchange surface is reduced, so that the heat exchanger can operate efficiently for a long time in the dusty flue gas.

Owner:XI AN JIAOTONG UNIV

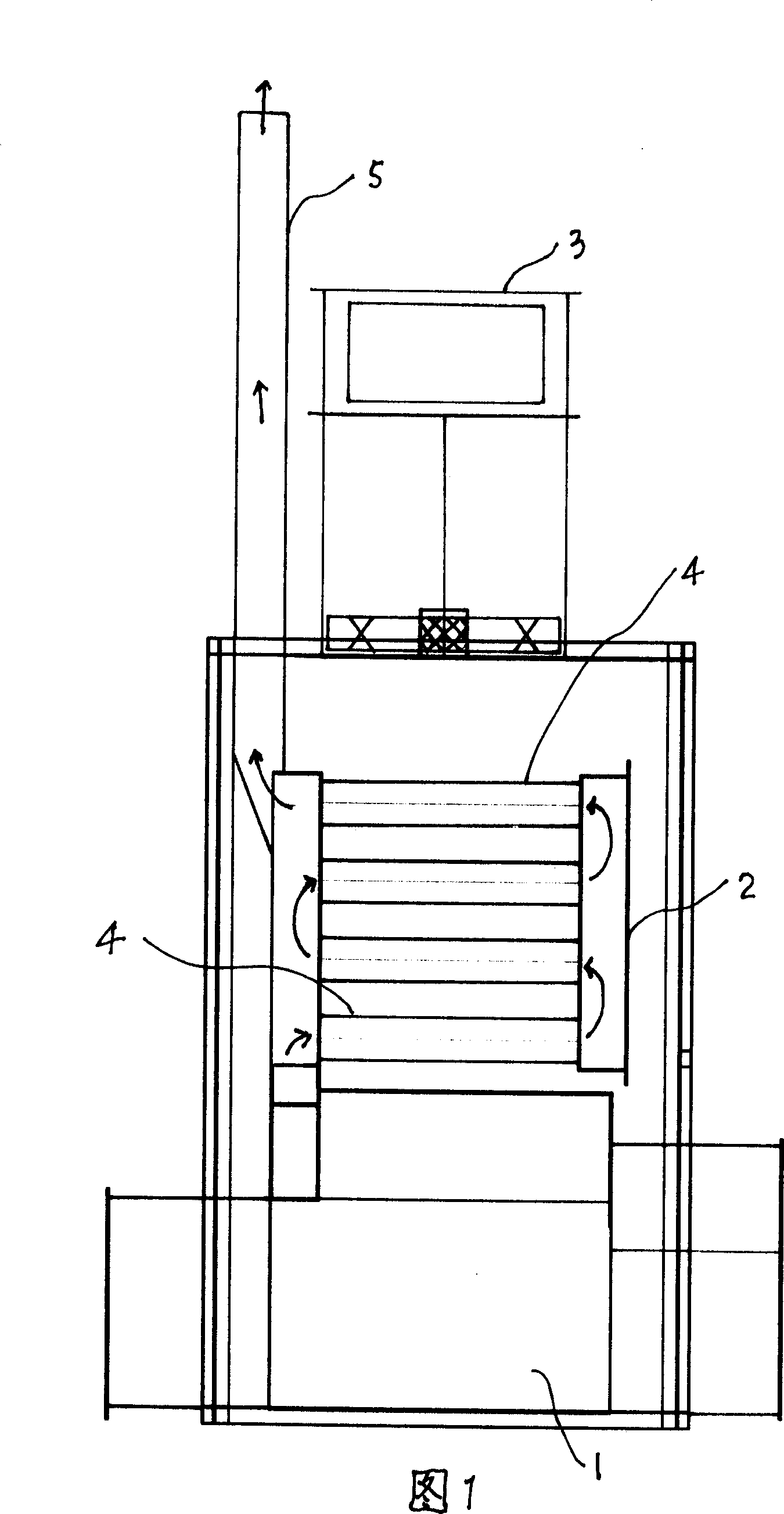

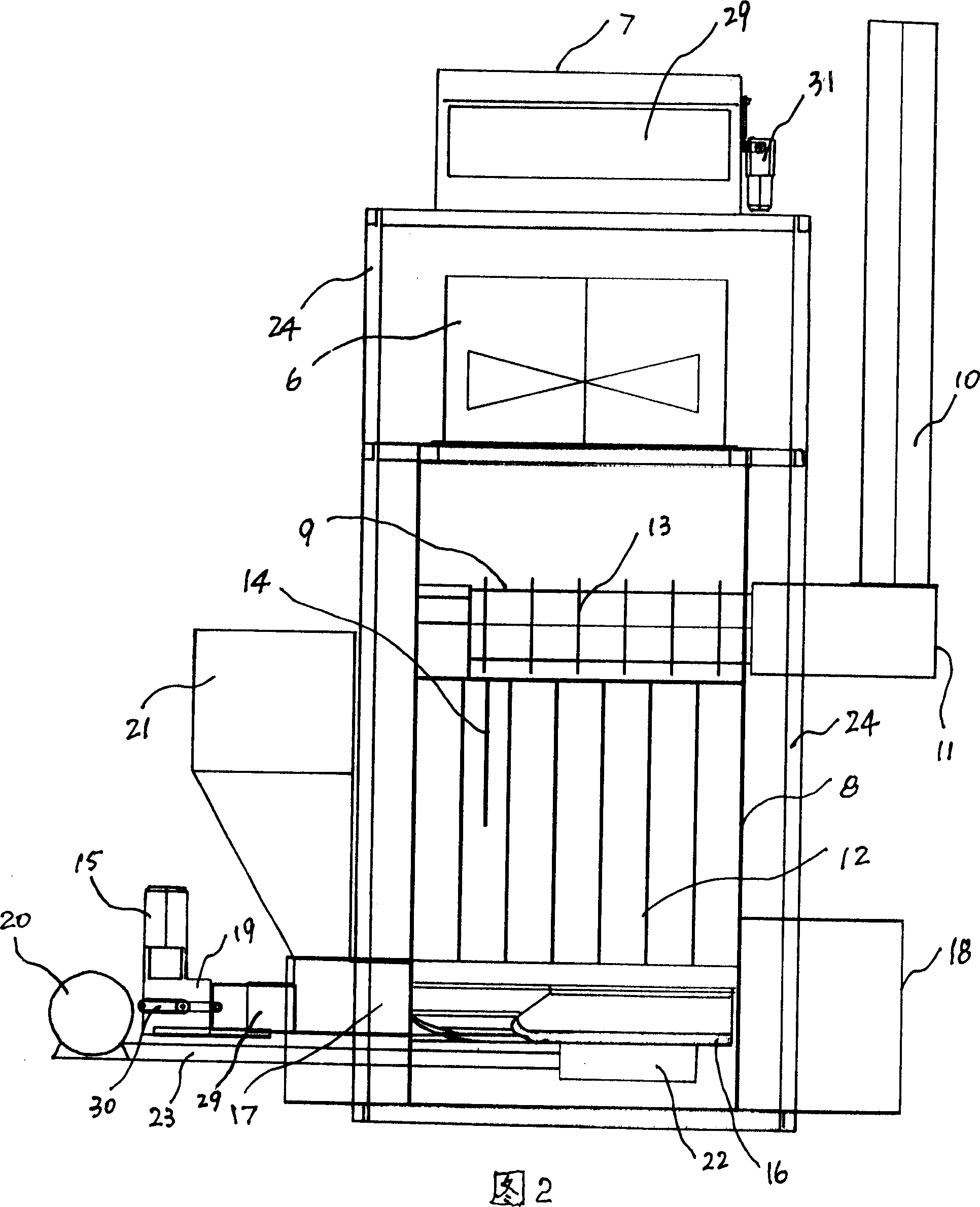

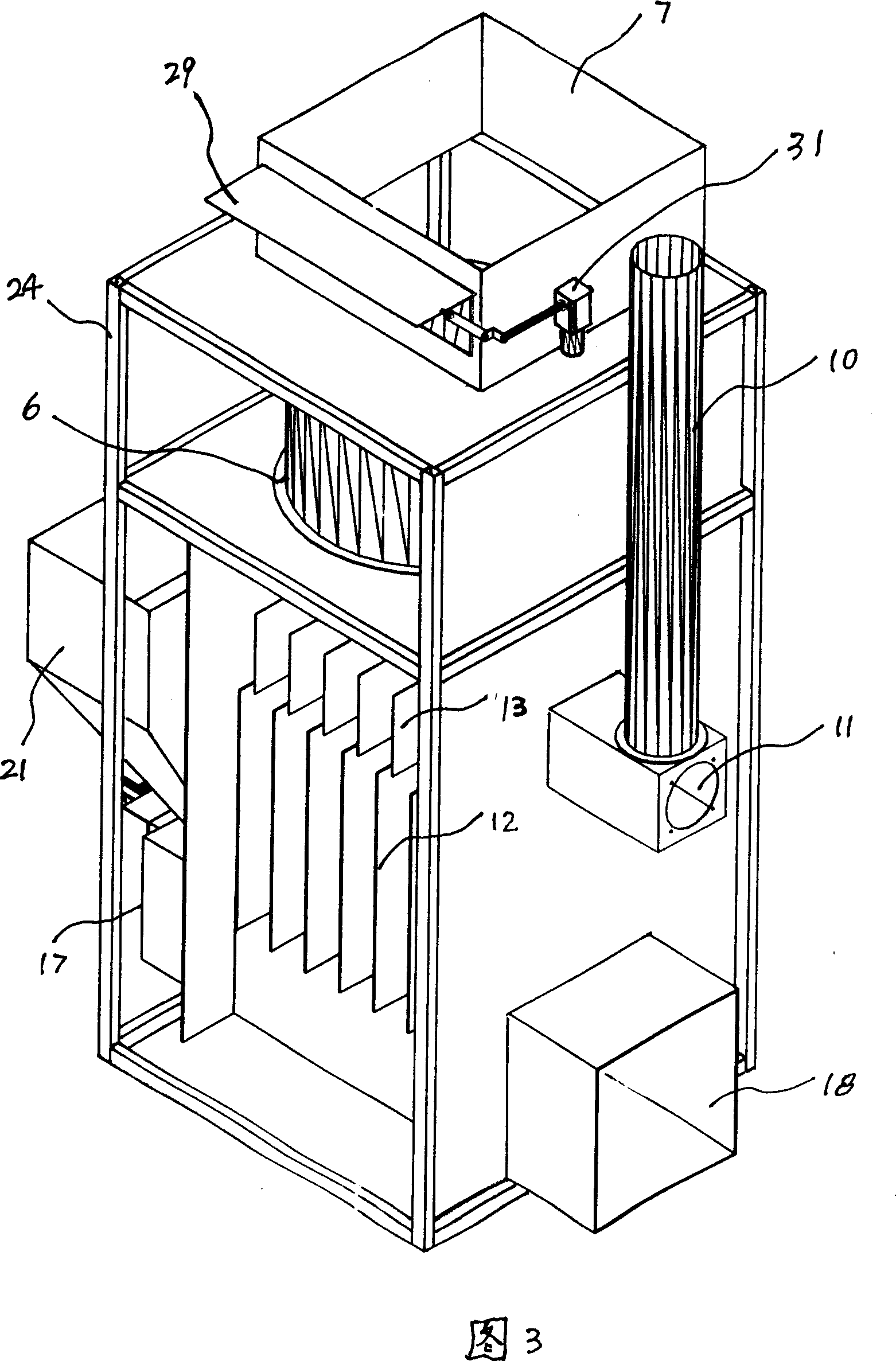

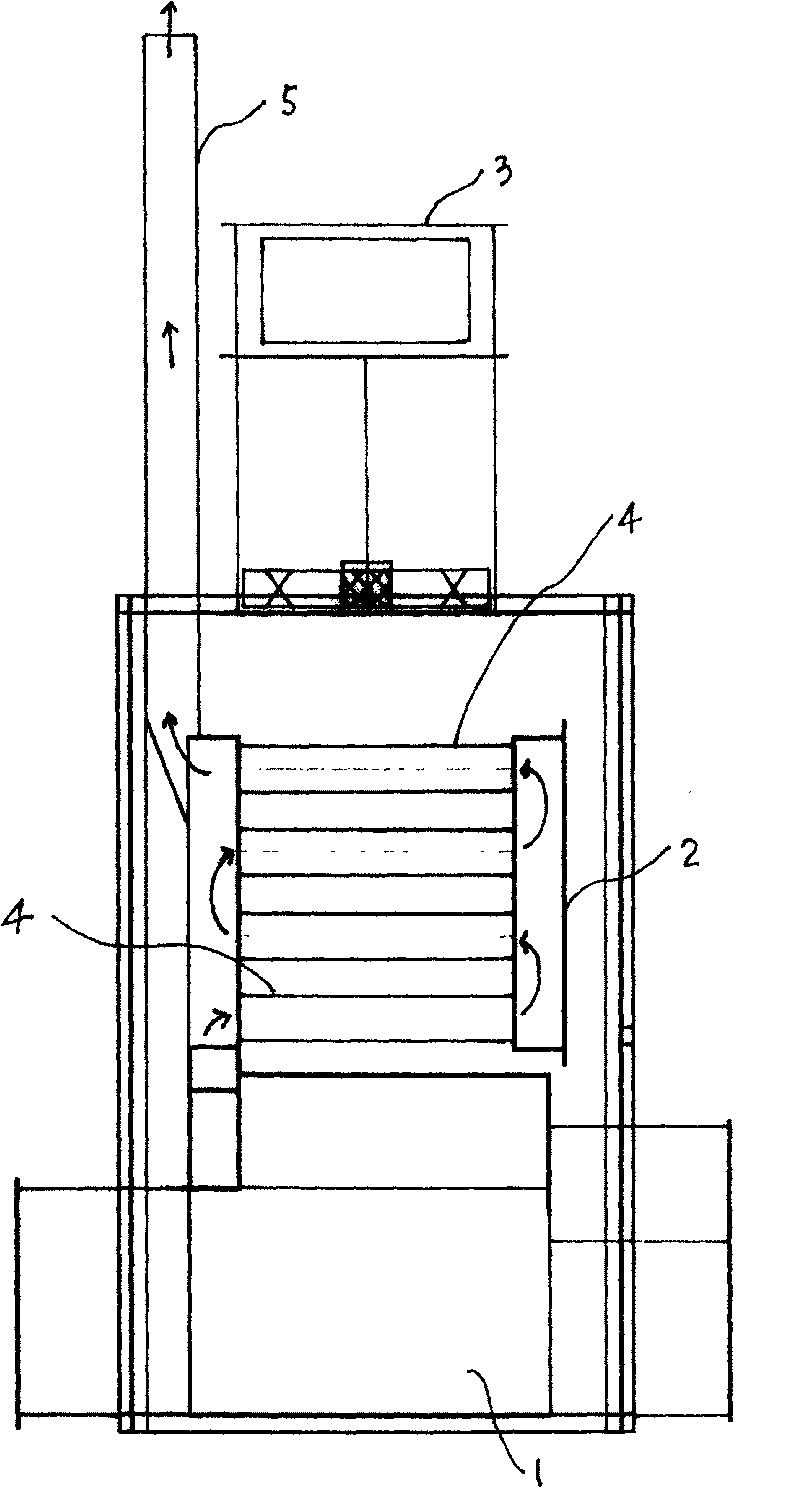

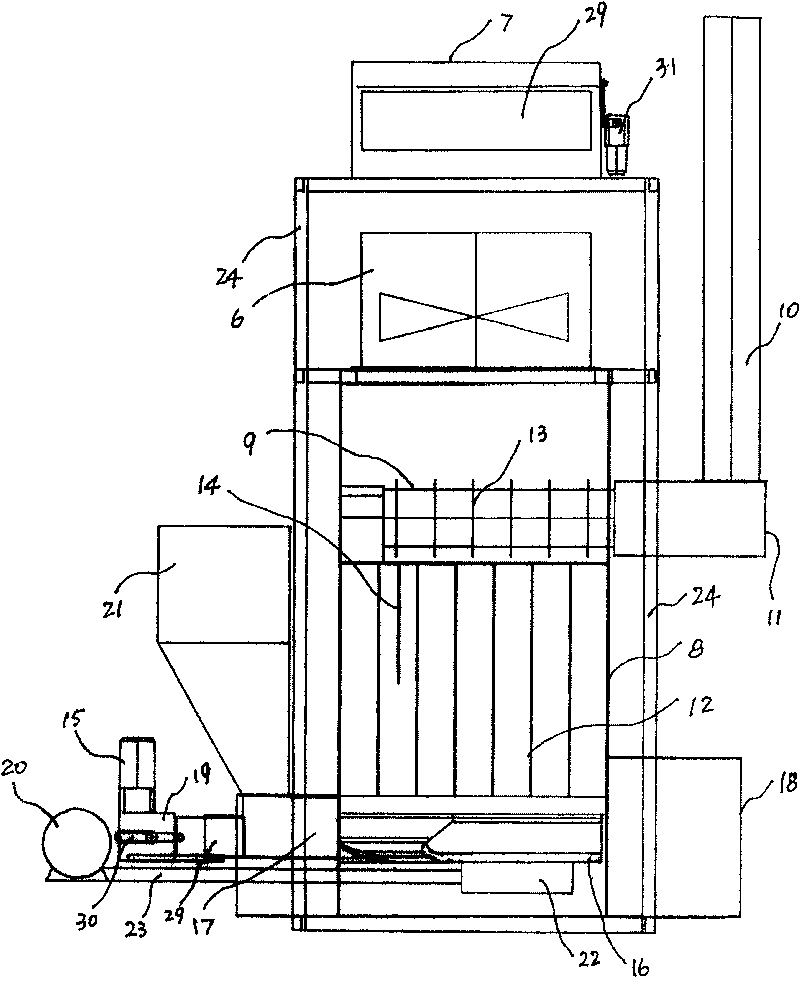

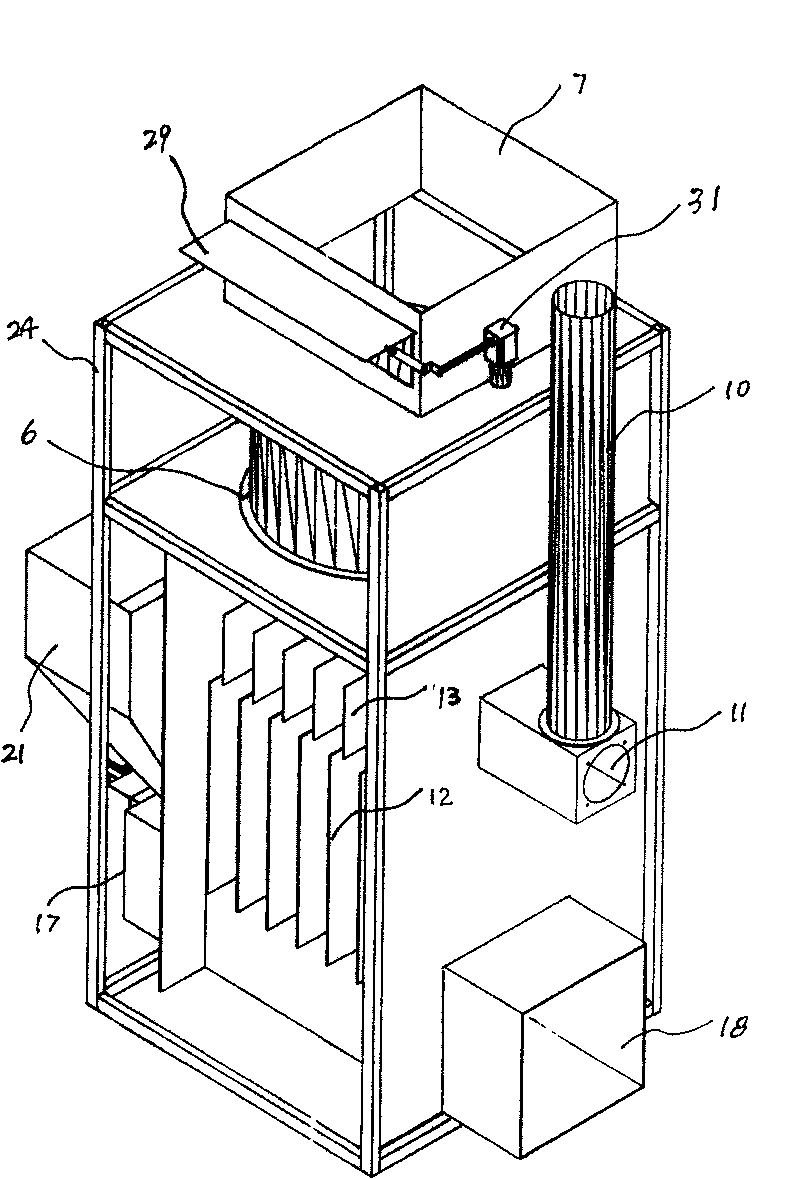

Coal burning hot-blast stove

The present invention belongs to the field of thermal equipment technology, and is especially coal burning hot blast stove. The coal burning hot blast stove has one casing, one blower in the upper part of the casing, one burning energy changer comprising burning hearth and heat exchanger in the middle part, one transverse flue connected between the burning energy changer and the chimney and with soot door, vertical cooling fins outside the burning energy changer and the flue, one hot blast cavity formed between the casing and the burning energy changer and the flue, one coal feeding port and one cleanout door below the burning energy changer. The burning energy changer is heated by flame under it, and the heat in the burning energy changer and the flue are carried out by the air from the blower. The coal burning hot blast stove has convenient soot and slag elimination and high heat efficiency.

Owner:康秉荣

Liquid coke inhibitor

InactiveCN102329676AReduce dust accumulationHas cleaning effectFuel additivesBULK ACTIVE INGREDIENTOxygen

The invention discloses a liquid coke inhibitor, and belongs to the technical field of clean coal combustion. Main active ingredients of the liquid coke inhibitor are an organic surfactant and nitrate. When the organic surfactant is at high temperature, an organic polymer compound has a dirt cleaning effect, and the organic polymer compound is reacted at high temperature to generate a large number of air bubbles so as to make coke blocks loose. The nitrate can generate microexplosion and release oxygen at high temperature, can continuously release oxygen in a range from low temperature to high temperature to make soot formation and carbon deposition layers on different parts loose and contribute to more fully combusting pulverized coal; metal ions in the nitrate can promote low melting point compounds in a coke layer to be converted into loose high melting point compounds, which can contribute to removing a coking layer and prevent high temperature corrosion.

Owner:SNTO TECH GRP

Controlled-Release Fertilizer

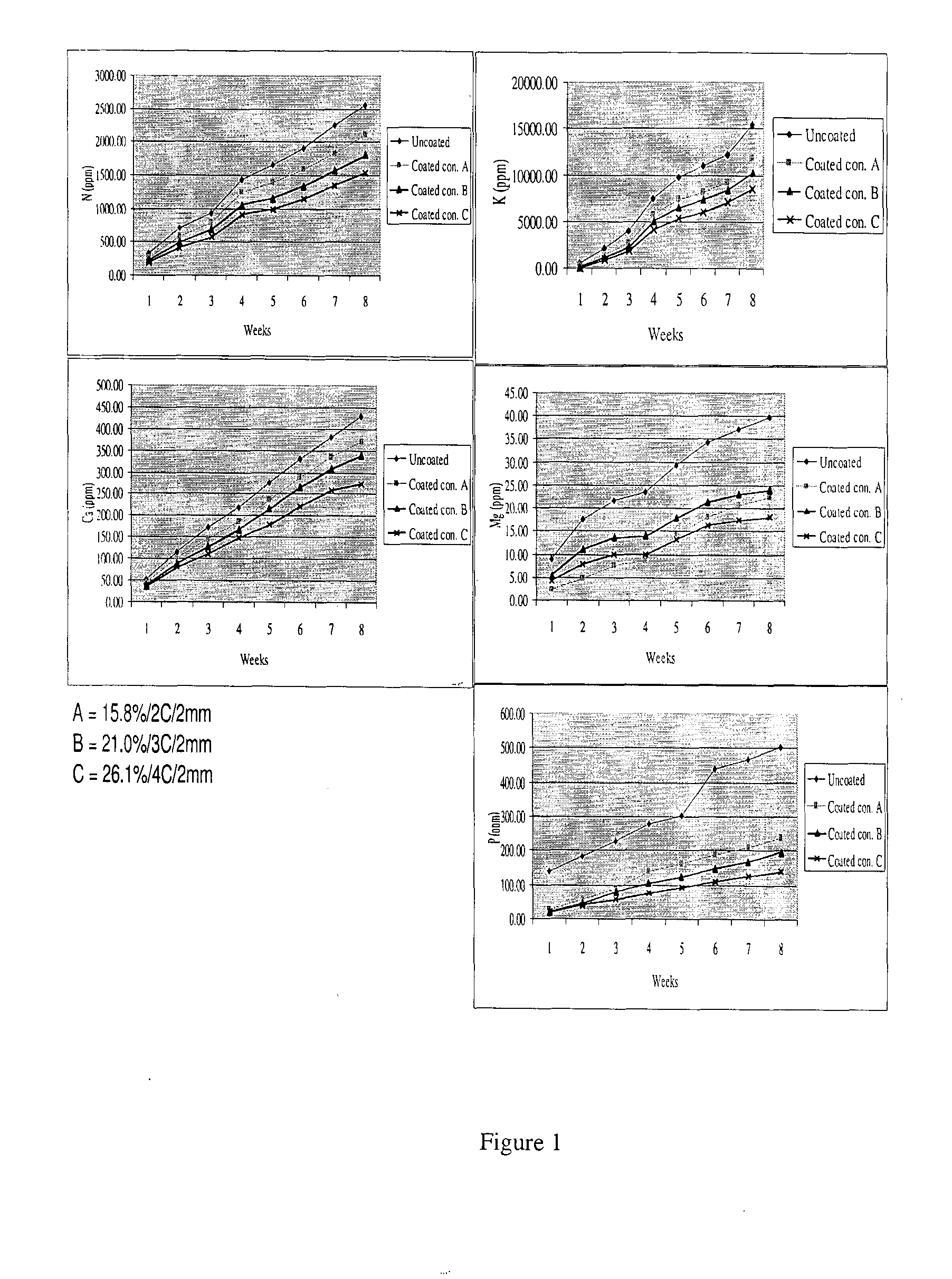

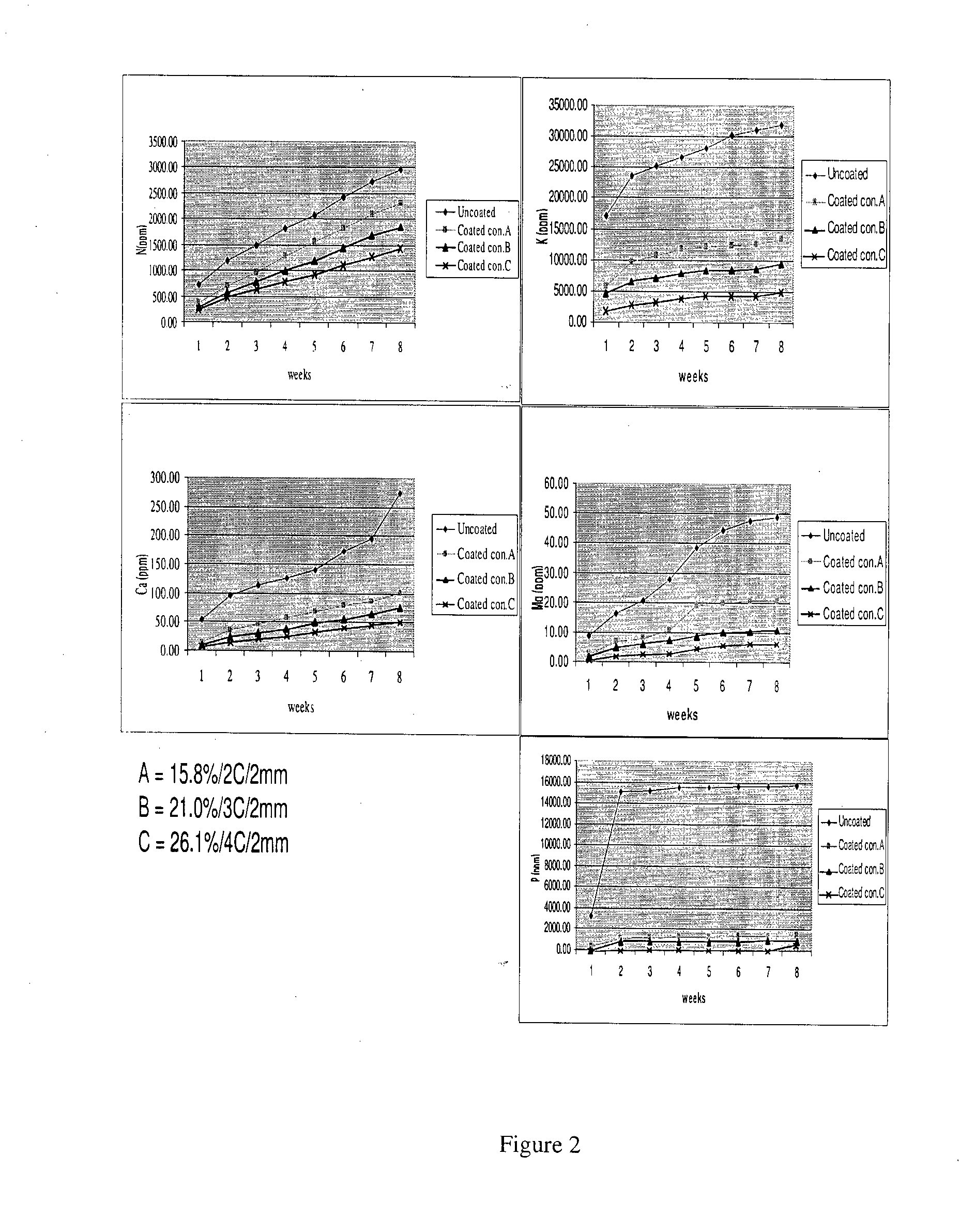

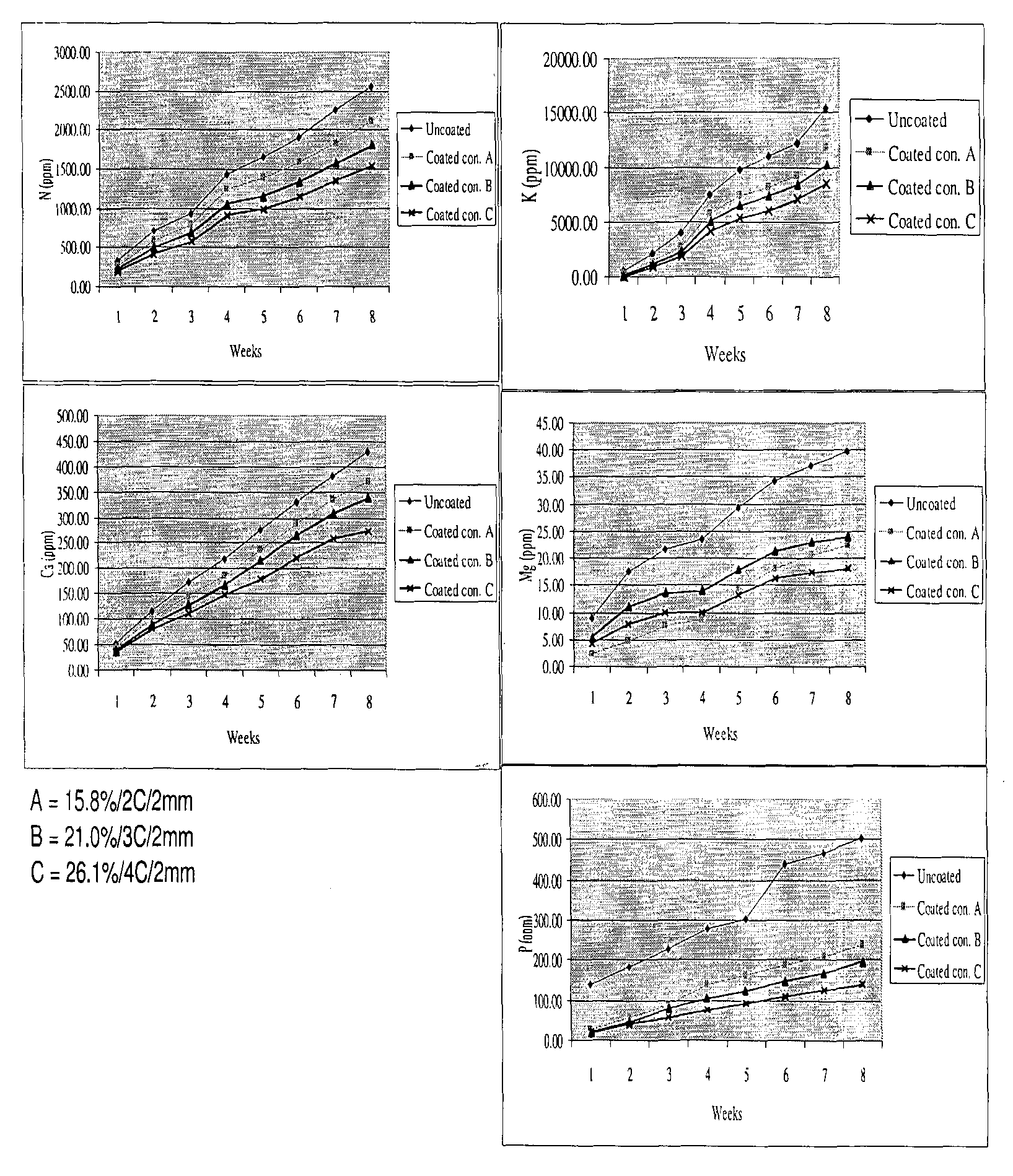

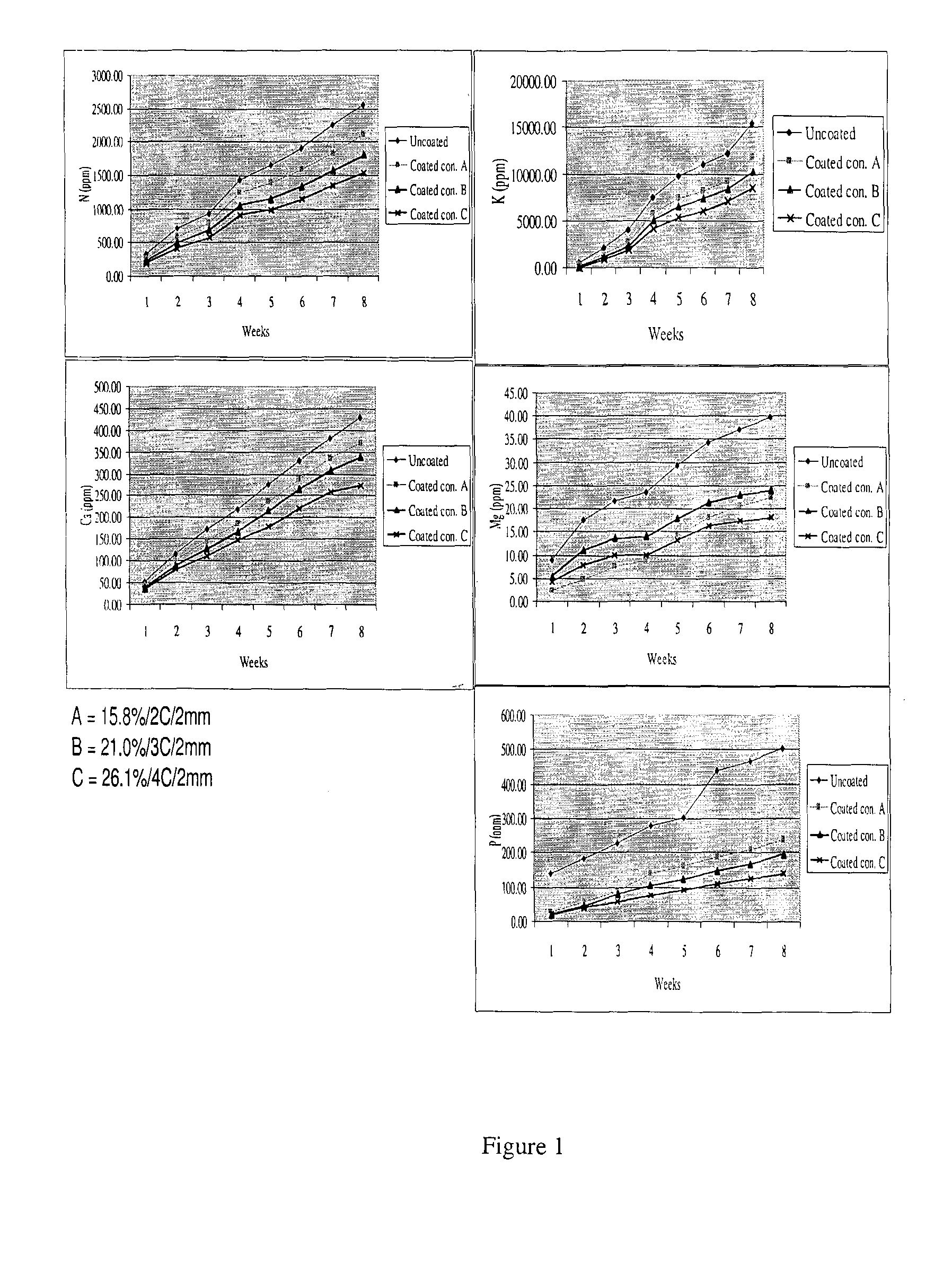

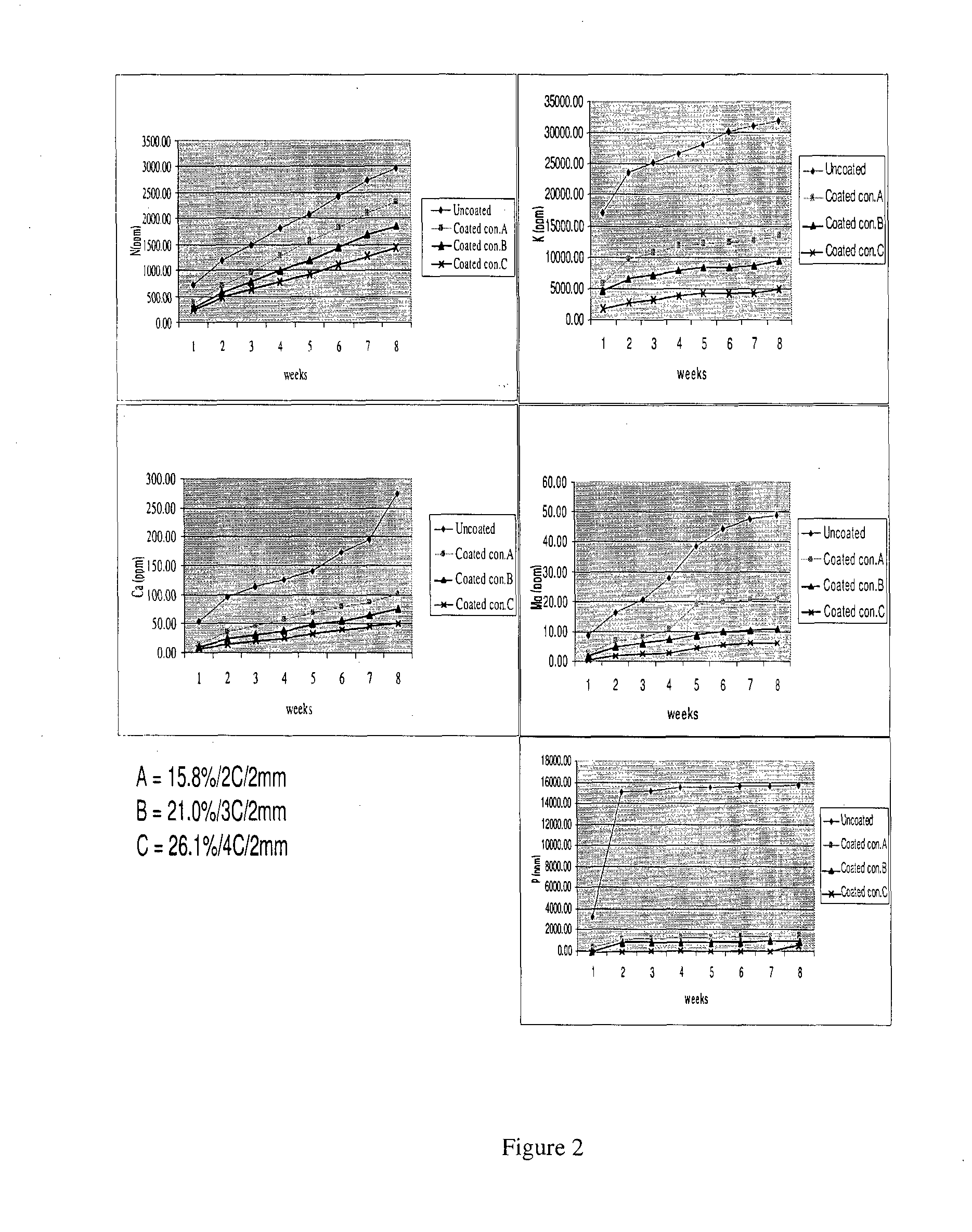

InactiveUS20140290319A1Increase resistanceEfficient releaseOrganic fertilisersLayered/coated fertilisersPolyolControl release

A controlled-release fertilizer comprising fertilizer particles encapsulated in a biodegradable polyurethane obtained from a reaction between a polyisocyanate and an isocyanate-reactive component, which is formed by a polyol and a methyl ester derivative of a natural oil, in the presence of an amine catalyst.

Owner:MALASIAN PALM OIL BOARD

Controlled-release fertilizer

InactiveUS9090517B2Efficient releaseIncrease resistanceNitrogenous fertilisersOrganic fertilisersControlled releasePolyol

A controlled-release fertilizer comprising fertilizer particles encapsulated in a biodegradable polyurethane obtained from a reaction between a polyisocyanate and an isocyanate-reactive component, which is formed by a polyol and a methyl ester derivative of a natural oil, in the presence of an amine catalyst.

Owner:MALASIAN PALM OIL BOARD

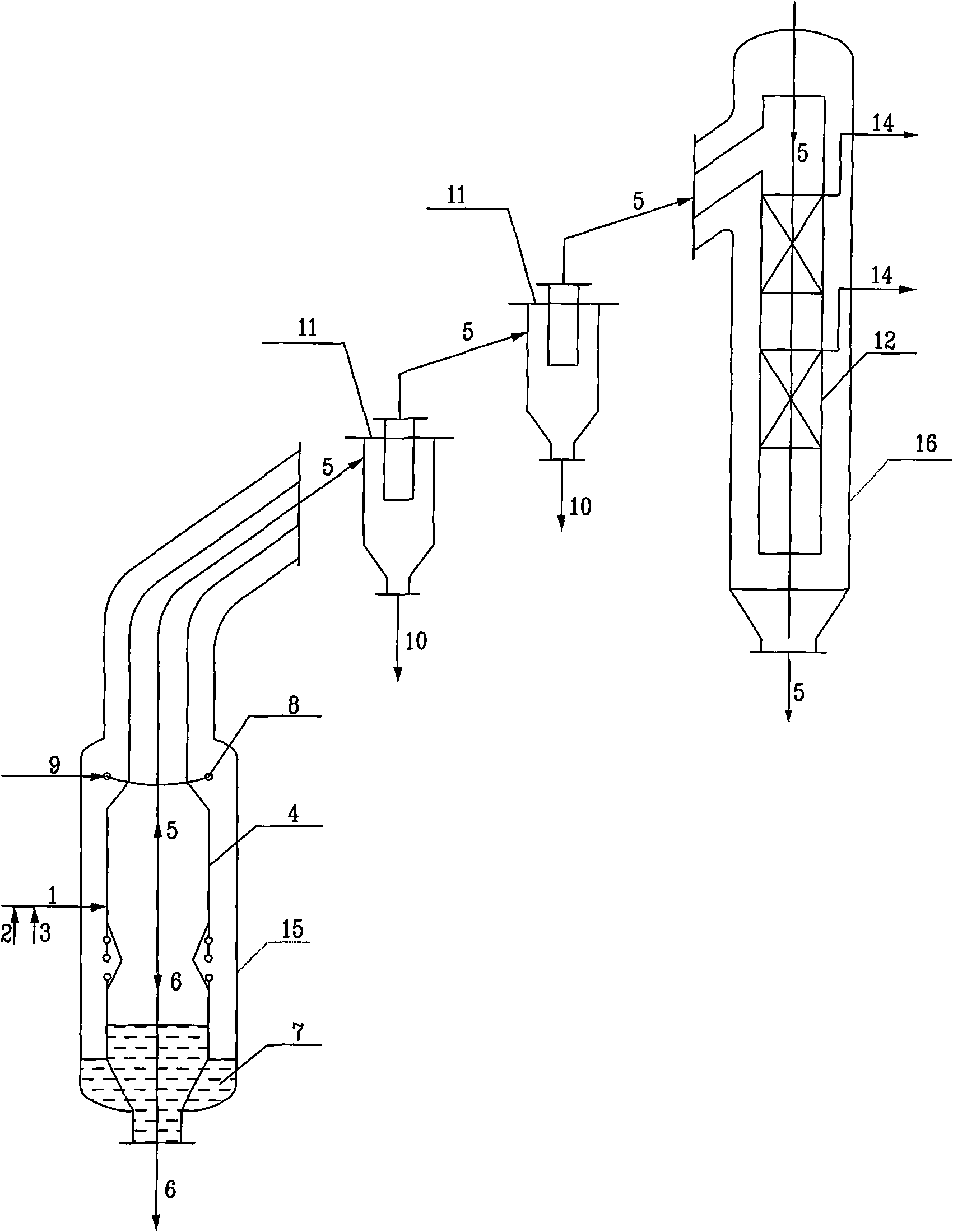

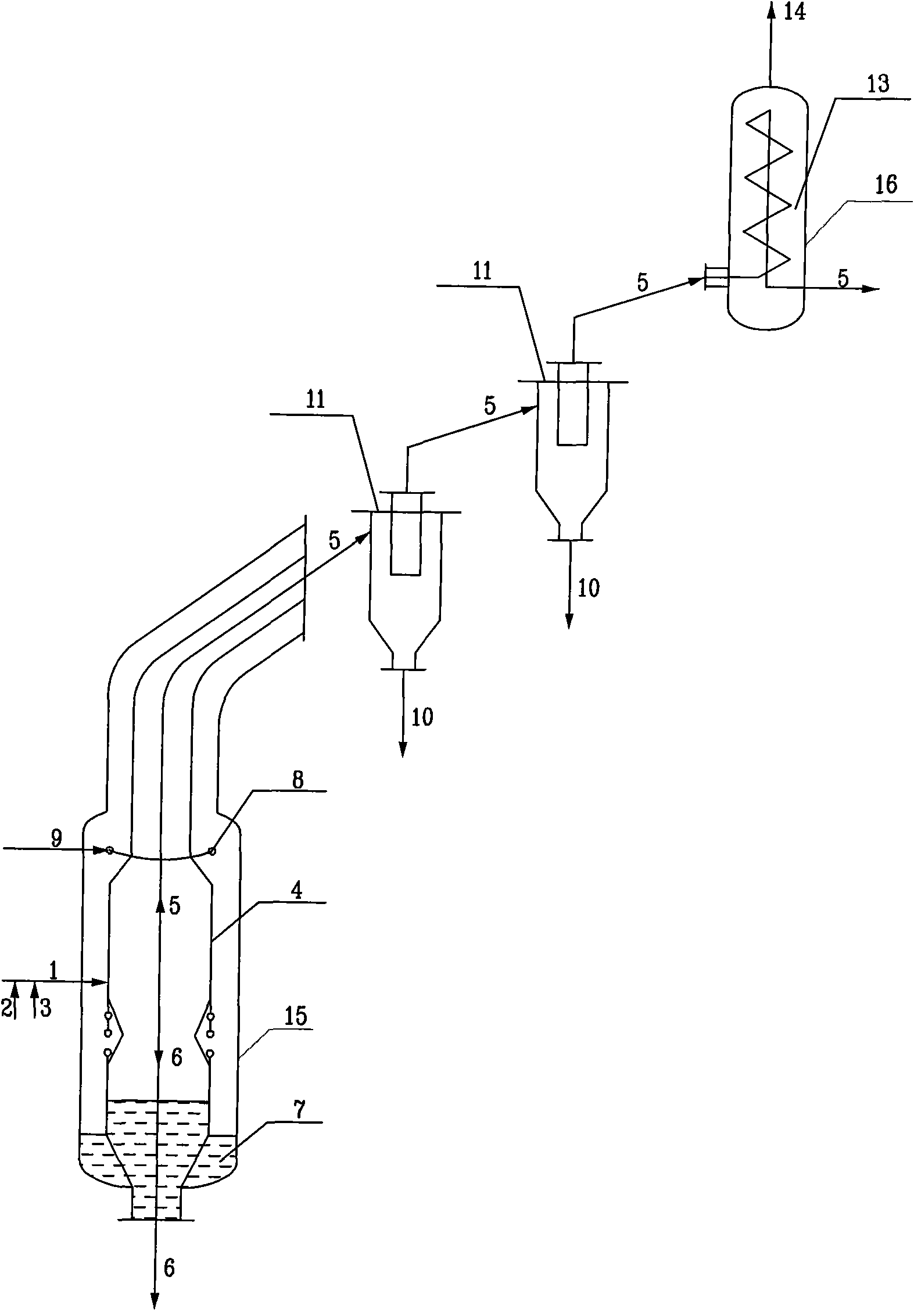

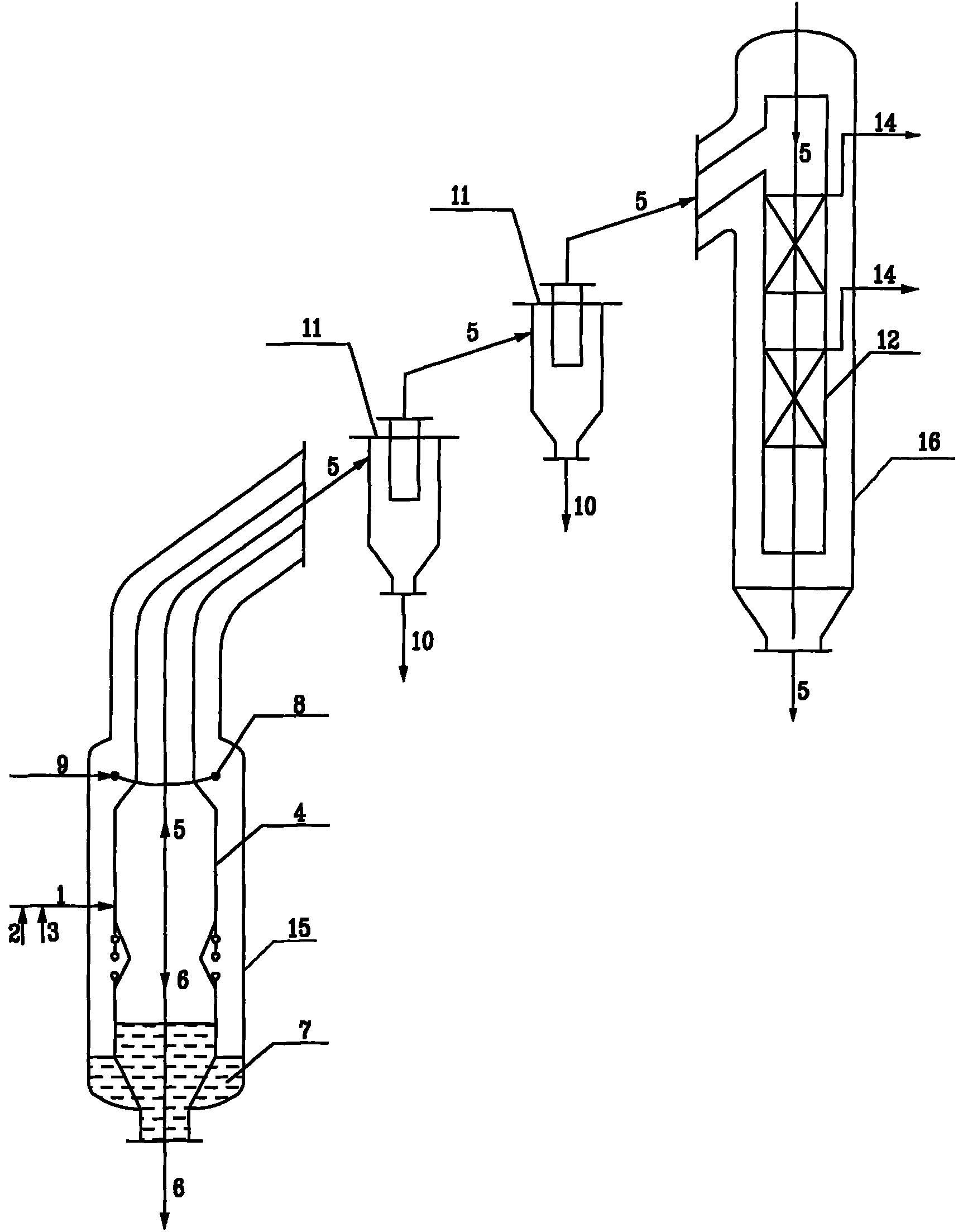

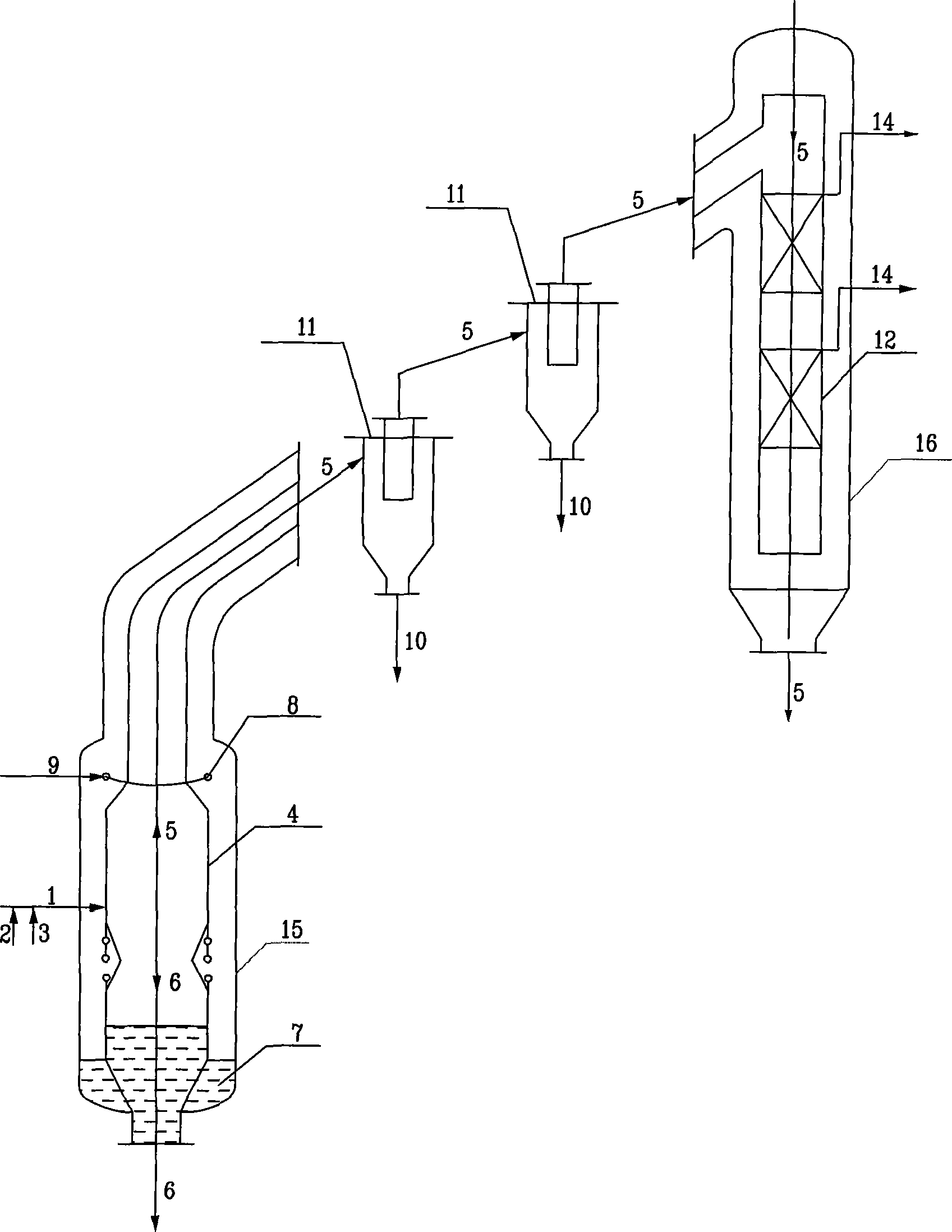

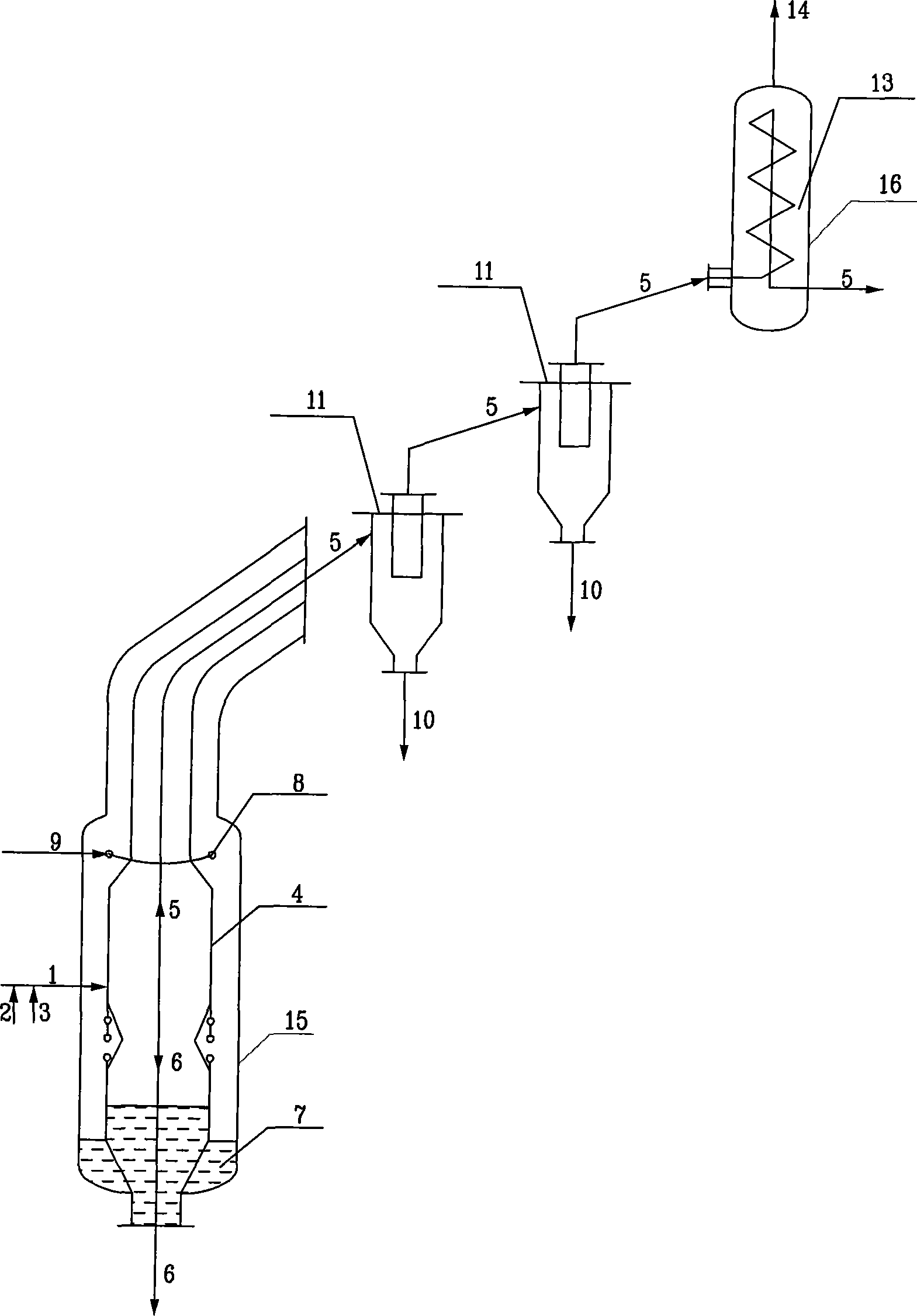

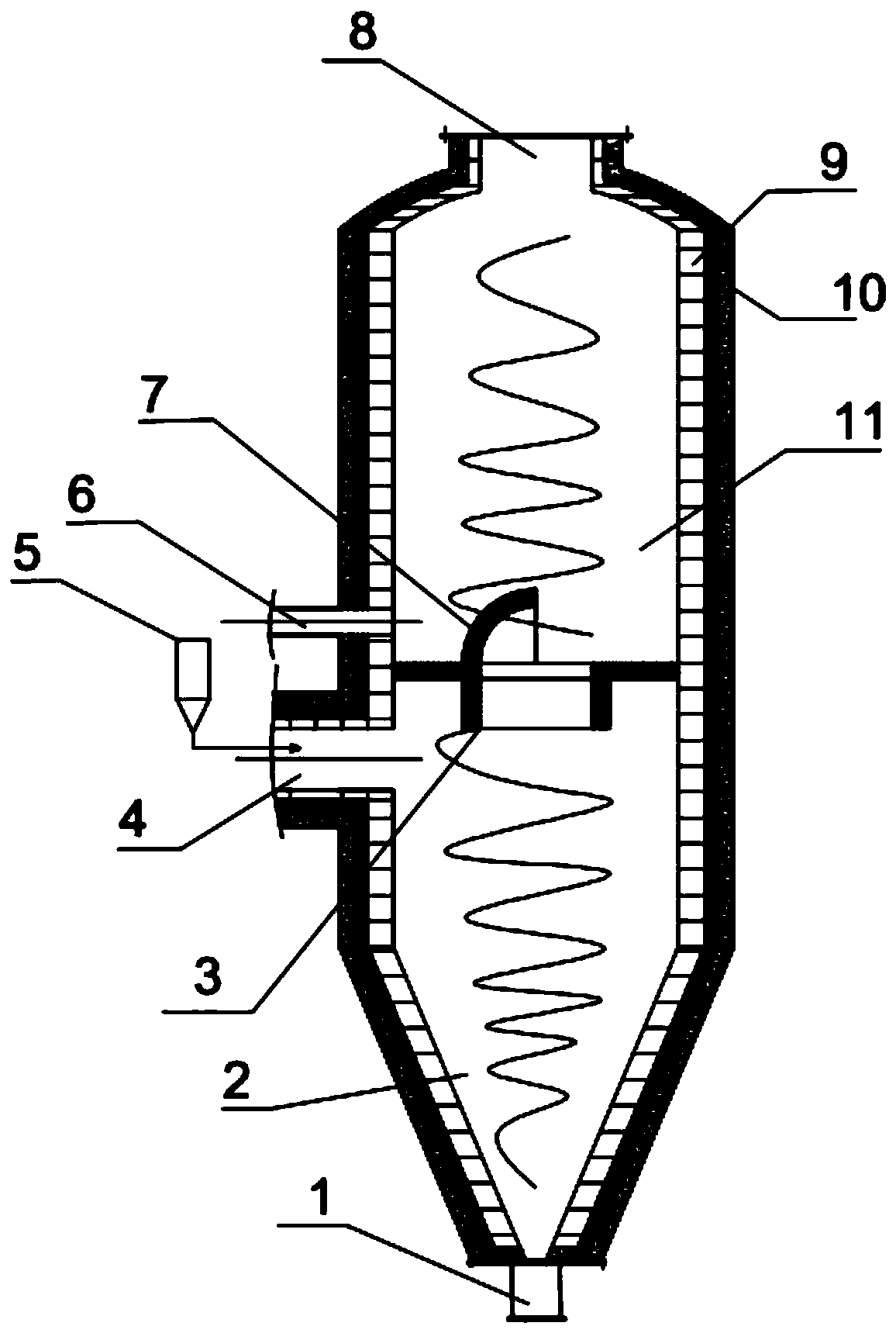

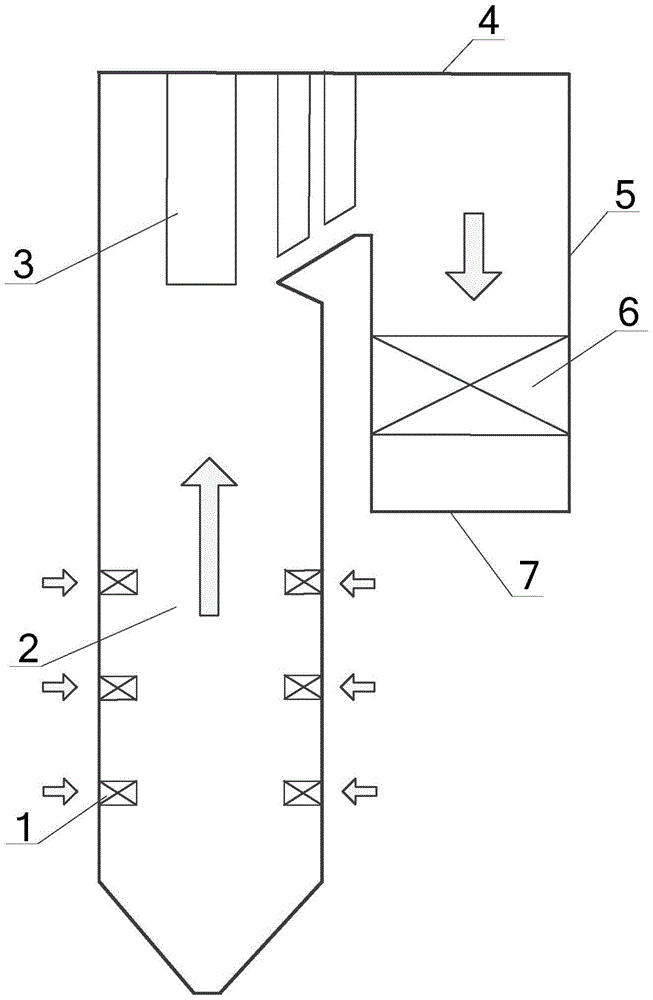

Gasification method of carbon-containing solid raw material and used reactor

ActiveCN102041106AGuaranteed stabilityGuaranteed continuityEnergy inputCombustible gas productionSyngasSlag

The invention relates to a gasification method of a carbon-containing solid raw material and a used reactor. The gasification method is characterized by comprising the following steps of: reacting the carbon-containing solid raw material with oxygen in a reactor unit so as to generate synthesis gas, wherein ash flows downwards into a slag pool at the lower end of a gasification reactor in the slag form under the action of gravity force; allowing high-temperature synthesis gas which entrains molten ash residues to rise to a chill zone in the gasification reactor, injecting steam or / and water into the chill zone by using chilling equipment and chilling the high-temperature synthesis gas so as to freeze the molten ash residues entrained in the high-temperature synthesis gas into solid dust; introducing the synthesis gas which entrains the chilled solid dust into a dust removing unit so as to remove dust entrained in the synthesis gas; and introducing the synthesis gas into a waste boiler unit and generating steam by using process waste heat of the synthesis gas. The reactor provided by the invention isolates a gasification furnace from the waste boiler unit through respective shell and the dust removing unit is arranged between the gasification furnace and the waste boiler unit. The equipment has low wear rate and can run for a long time.

Owner:CHINA PETROCHEMICAL CORP +2

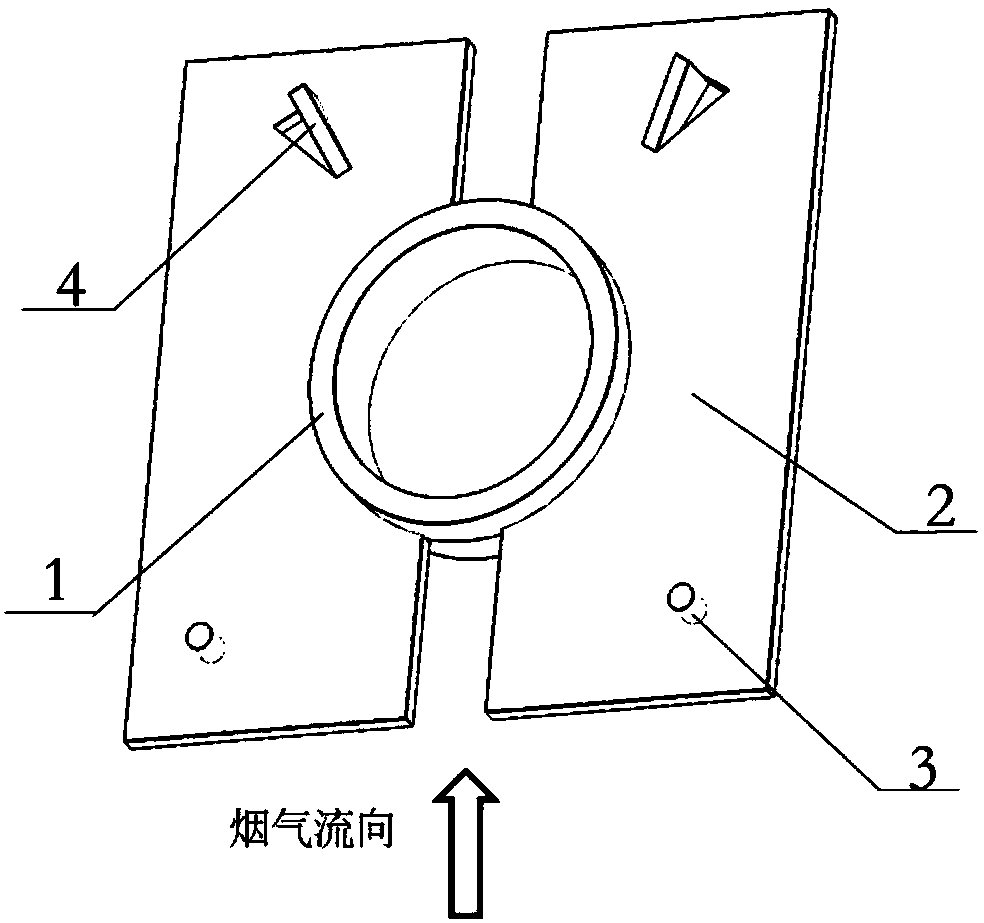

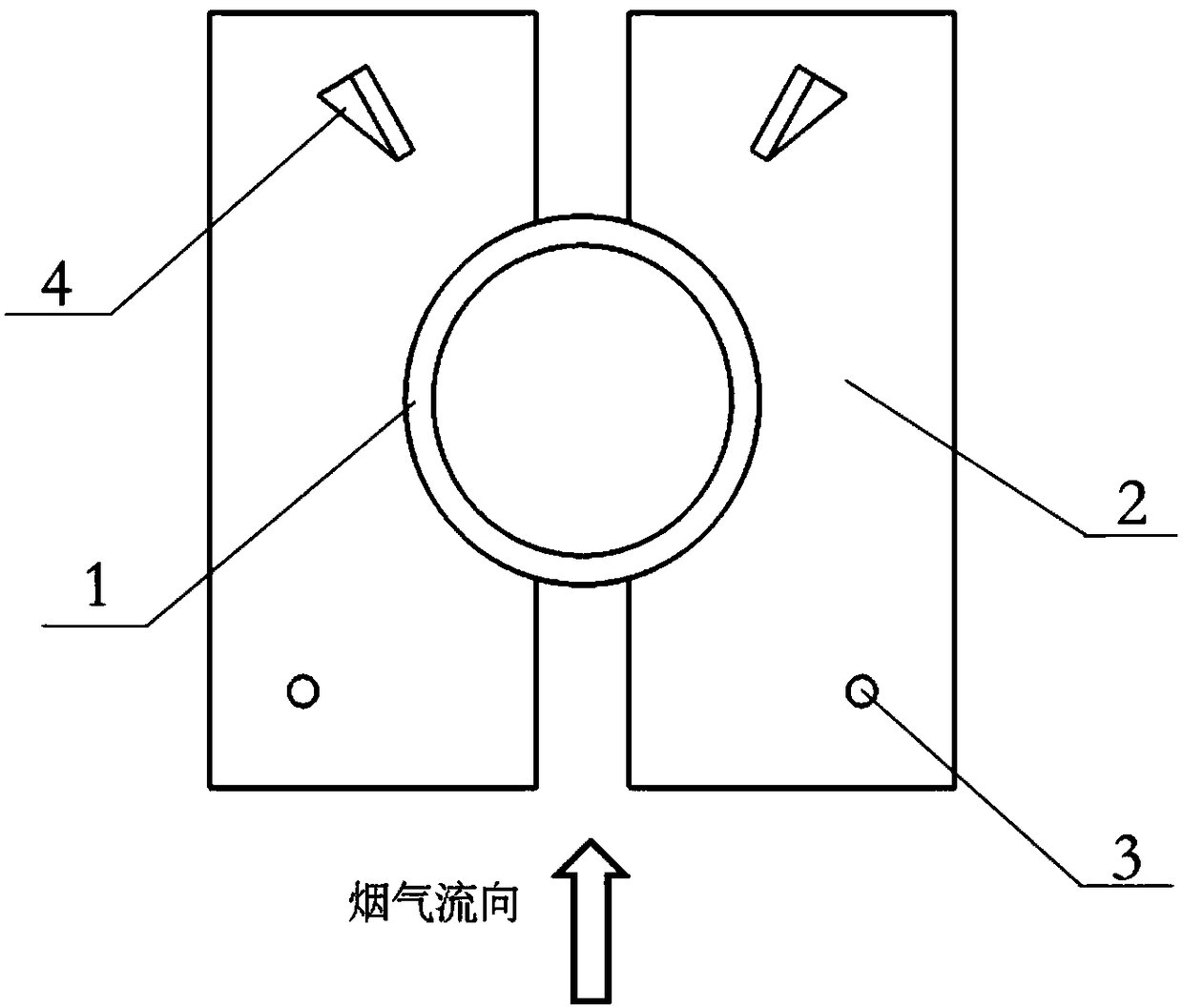

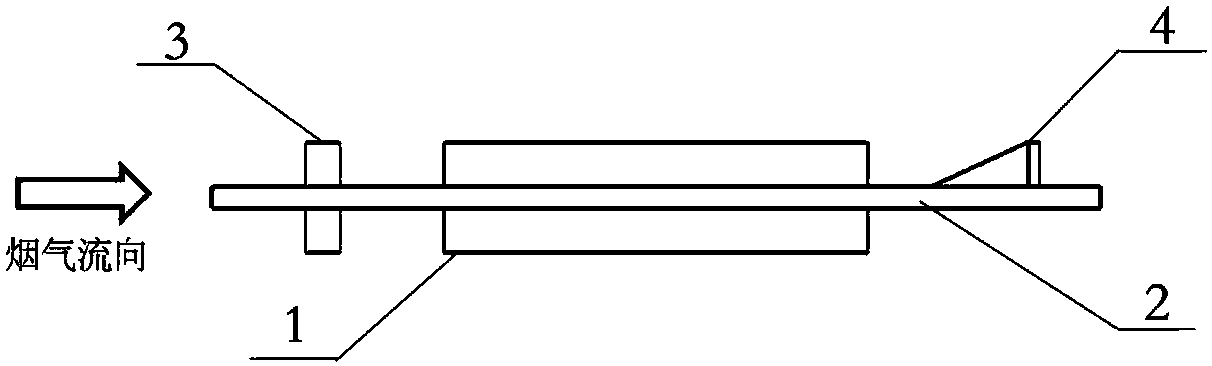

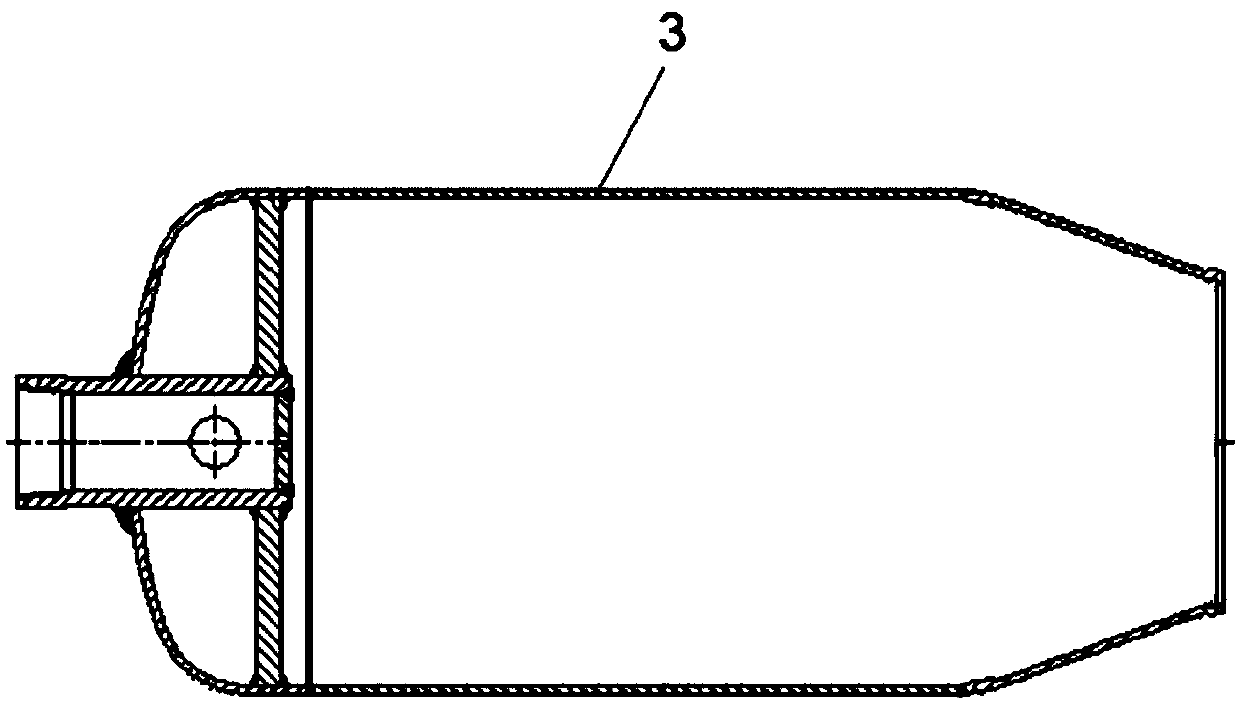

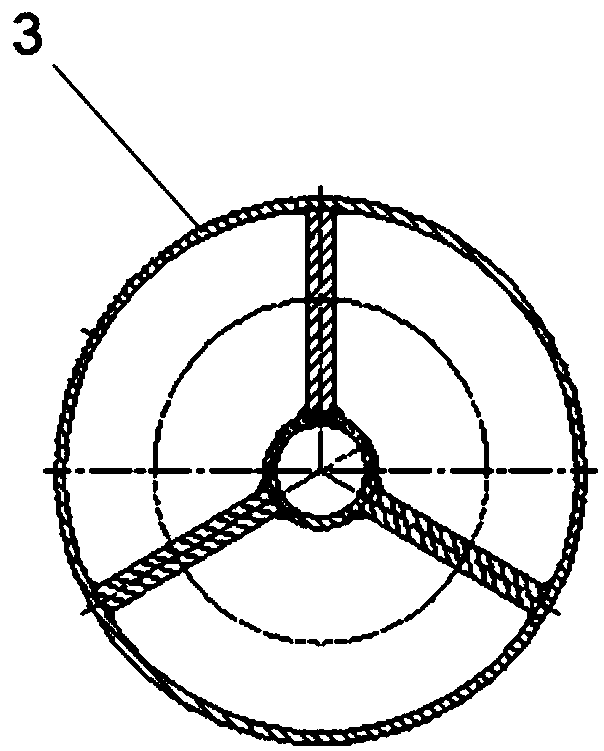

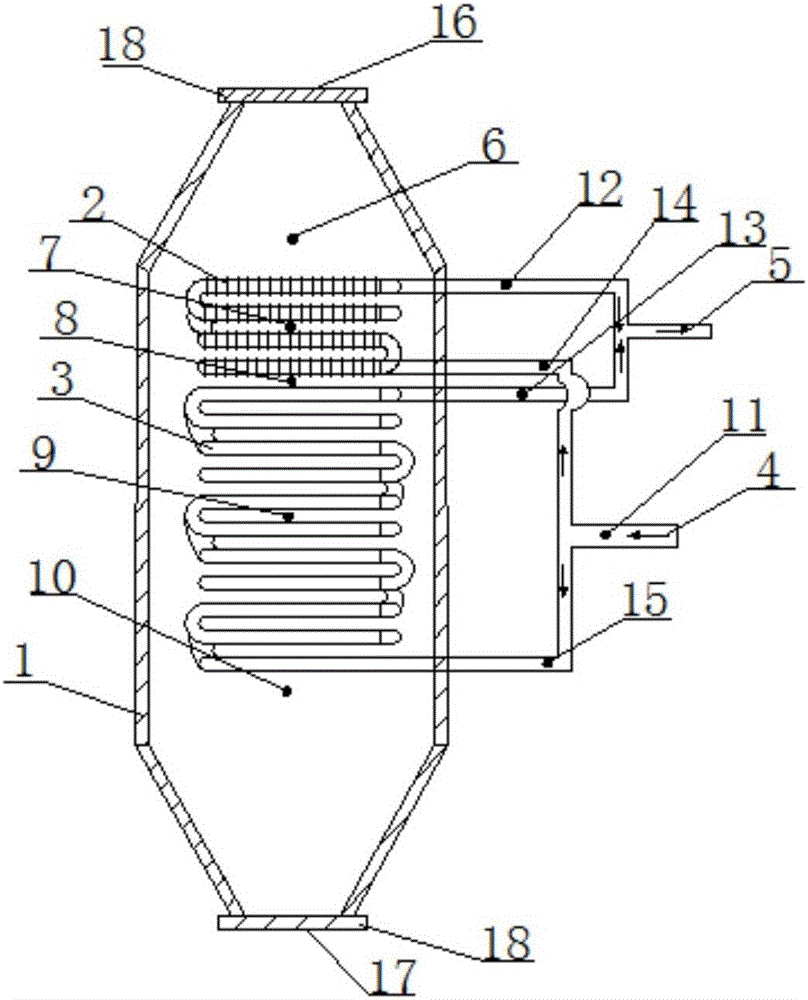

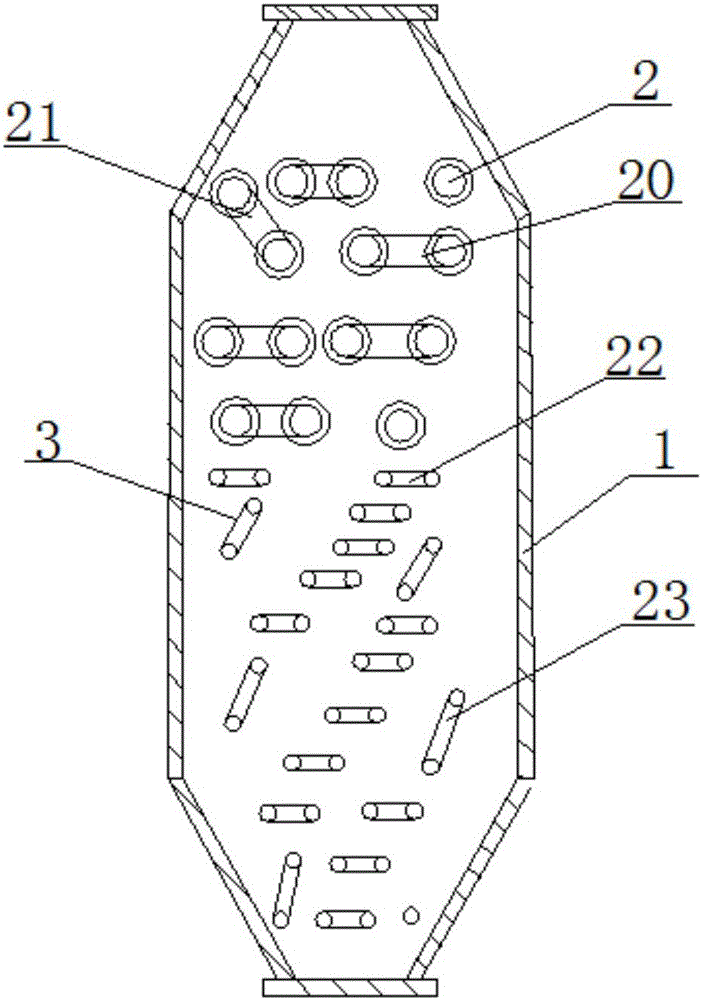

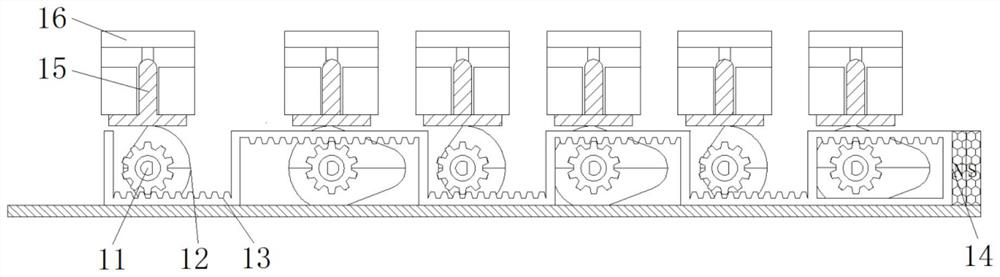

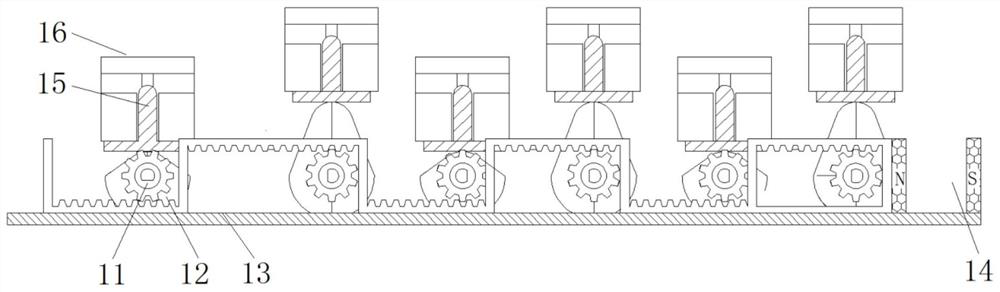

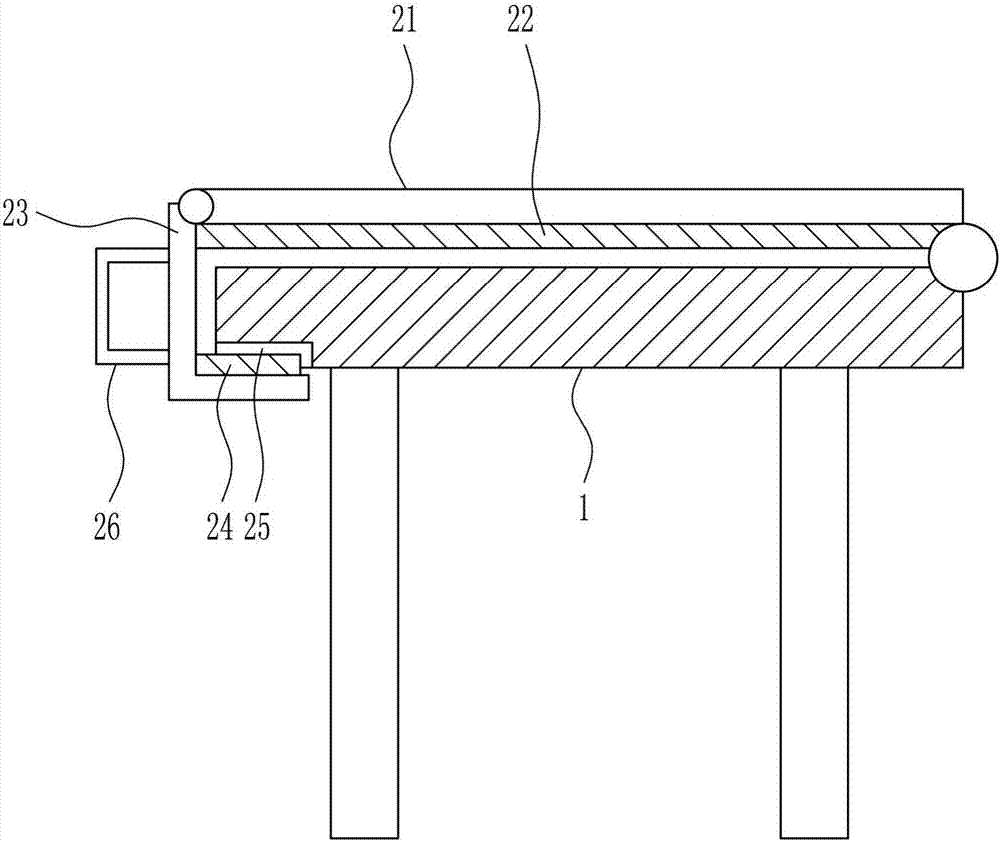

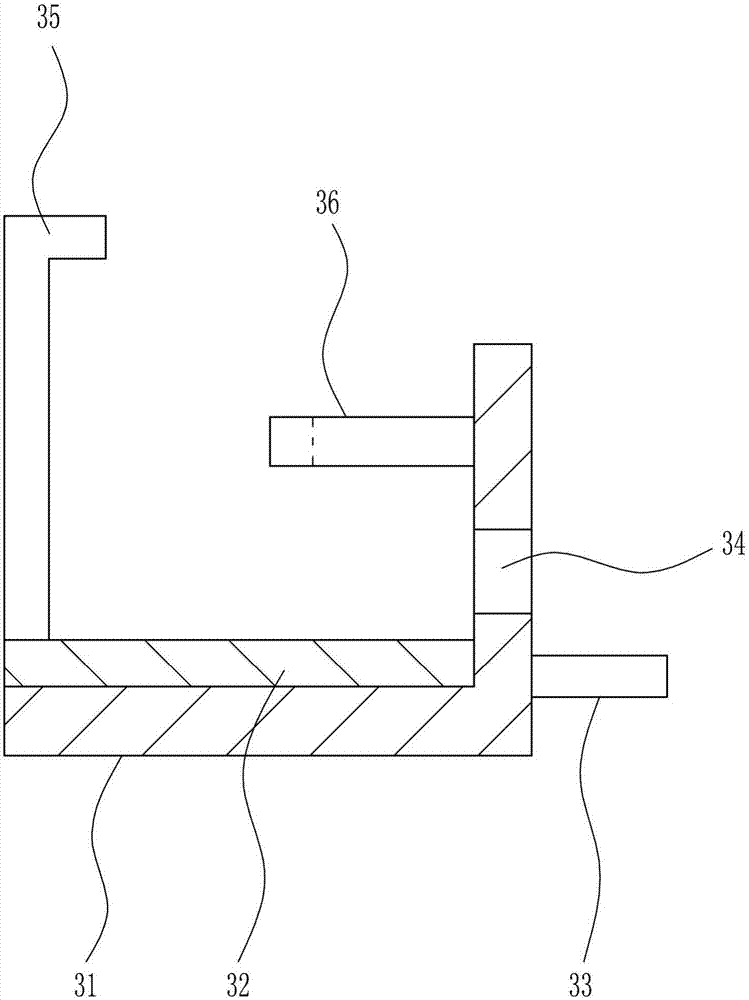

H-shaped finned pipe formed by combining turbulence rods and delta vortex generators

InactiveCN108362156AIncrease disturbanceSmall pressure drop lossHeat exchanger casingsTubular elementsEngineeringMechanics

The invention discloses an H-shaped finned pipe formed by combining turbulence rods and delta vortex generators. The H-shaped finned pipe comprises a base pipe and a plurality of parallel H-shaped finsets, and the base pipe is sleeved with the H-shaped fin sets. Each H-shaped fin set comprises two fins. Multiple pairs of turbulence rods are symmetrically arranged on the windward side of the two fins, located on the two sides of the base pipe, of each H-shaped fin set, wherein one pair of delta vortex generators is arranged on the leeward side symmetrically. The turbulence rods axially penetrate through the fins on the windward side and on the two sides of the base pipe. The included angle of the incoming-flow directions of the delta vortex generators is 30 degrees-40 degrees. When smoke flows through the fins, the turbulence rods and the delta vortex generators conduct induction to generate secondary flow, disturbance is generated to fluid, and thus the purpose of heat exchange enhancement is achieved. The turbulence rods disturb airflow, the development of a boundary layer is prevented, pressure drop loss is lowered, deposition of particles in smoke on the heat exchange surface is reduced, and long-time efficient operation of a heat exchanger is facilitated.

Owner:XI AN JIAOTONG UNIV

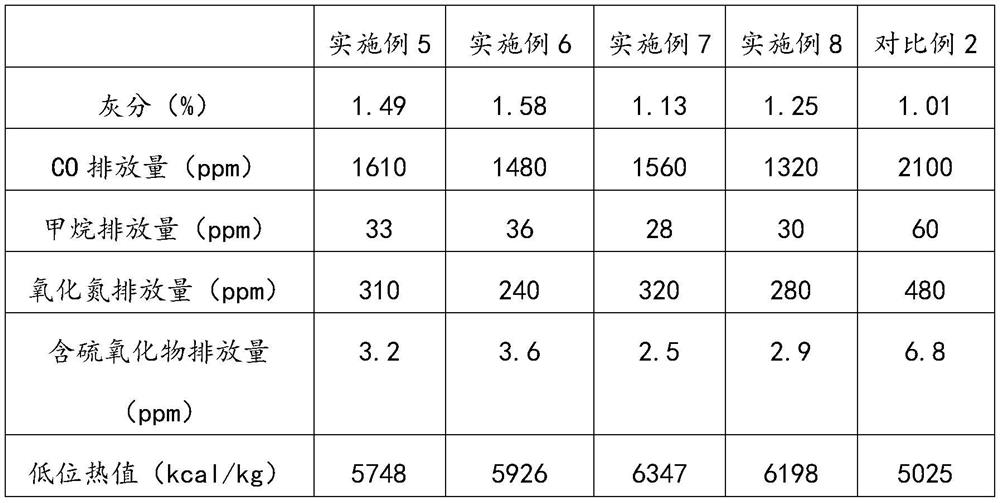

Low-corrosivity environment-friendly biomass solid briquette fuel

InactiveCN106753665AImprove bond strength and durabilityGood integrityBiofuelsSolid fuelsBriquetteBiomass

The invention discloses a low-corrosivity environment-friendly biomass solid briquette fuel which is prepared by the following steps: pulverizing a biomass raw material, mixing the pulverized biomass raw material with fuel additives, drying, and carrying out hot pressing. The biomass raw material is composed of crop straws, peanut shells and shoddy and little fuelwood; the fuel additives are composed of a dehydrating agent, a combustion improver and a solid absorbent; and the weight ratio of the biomass raw material to the fuel additives is 100:(4-9). By using the shoddy and little fuelwood containing abundant lignin as the main biomass raw material, the abundant lignin performs the function of bonding under the combined actions of temperature and pressure, thereby enhancing the bonding strength and durability of the biomass solid briquette fuel; and thus, the biomass solid briquette fuel can not easily become loosened, and has favorable completeness in the transportation process. Nano aluminum powder used as the combustion improver can greatly enhance the combustion efficiency and combustion stability. Kaolin powder and / or coal gangue powder are / is used as the solid absorbent, thereby greatly improving the soot deposition and corrosion conditions of the heating surface, and prolonging the service life of the combustor.

Owner:嘉兴市顶立生物科技有限公司

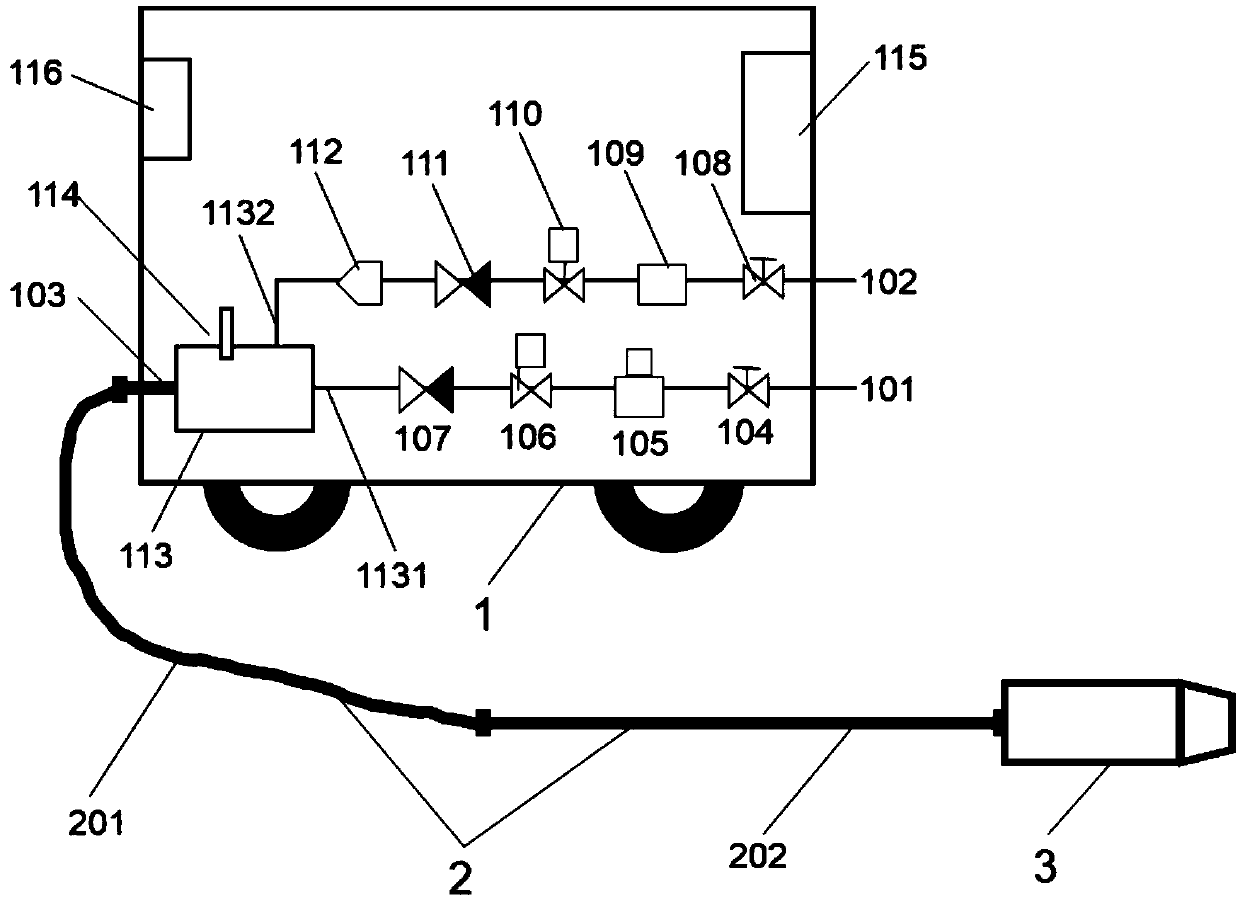

Movable gas shock-wave ash clearing gun

InactiveCN109084314ASolution rangeSolve the technical problems of many cleaning dead endsSolid removalFailure rateShock wave

The invention discloses a movable gas shock-wave ash clearing gun, and belongs to the technical filed of boiler ash clearing. The movable gas shock-wave ash clearing gun comprises an ignition controlbox; and the ignition control box specifically comprises an electrical control device, an air pipeline, a gas pipeline, a mixed ignition device, a gas delivering pipe and a set of replaceable gun barrel heads; an air inlet of the air pipeline is connected with an air source, a gas inlet of the gas pipeline is connected with a gas source, and the mixed ignition device is provided with an air inlet,a gas inlet, a mixed gas outlet, an ignition head and a connector of the ignition head; the gas delivering pipe comprises a soft connecting pipe, a hard connecting pipe and connecting accessories; and the replaceable gun barrel heads are connected with one end of the hard connecting pipe. The movable gas shock-wave ash clearing gun has the technical effects that ash clearing can be conducted in atargeted mode according to the ash accumulating situation of the heated surface of a boiler, the ash clearing efficiency is high, the movable gas shock-wave ash clearing gun is simple in structure, convenient to operate and low in production cost, and the operation failure rate of the movable gas shock-wave ash clearing gun is quite low.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

Method for reducing ash blocking of rotor of heating surface rotary air preheater

ActiveCN108870432AReduce heat lossReduce cloggingCombustion processIndirect carbon-dioxide mitigationAir preheaterElectrical control

The invention discloses a method for reducing ash blocking of a rotor of a heating surface rotary air preheater. When temperature sensors detect that the lowest temperature of surfaces of heat transfer elements in chambers which are located at one side of a rotor cold end is lower than 100 DEG C, an electric signal is sent to an electrical control system through the temperature sensors, the rotating speed of a rotor driven by a variable-speed motor is improved through the electrical control system, and the rotating speed of the variable-speed motor is kept until the lowest temperature of the cold end of the rotor exceeds 100 DEG C. The invention aims to provide the method for reducing the ash blocking of the rotor of the heating surface rotary air preheater, the ash accumulation and the scale accumulation on the surfaces of the heat transfer elements and the inner walls of the chambers can be reduced or avoided, cleaning of the accumulating ash on the surfaces of the heat transfer elements and the inner walls of the chambers is more convenient, the heat exchange efficiency is high, and the service life is long.

Owner:宁夏华能达环保科技开发有限公司

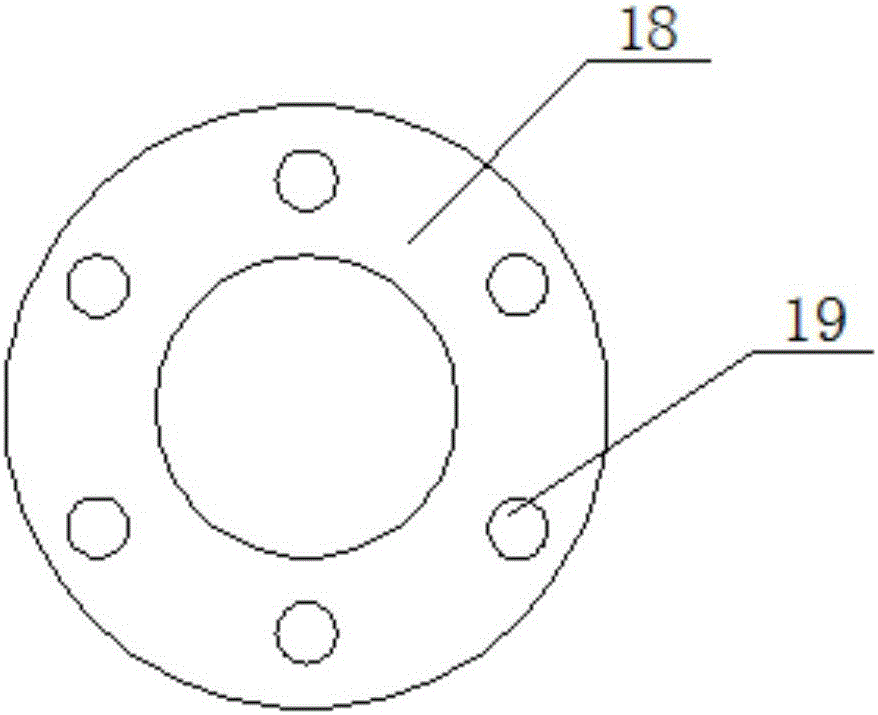

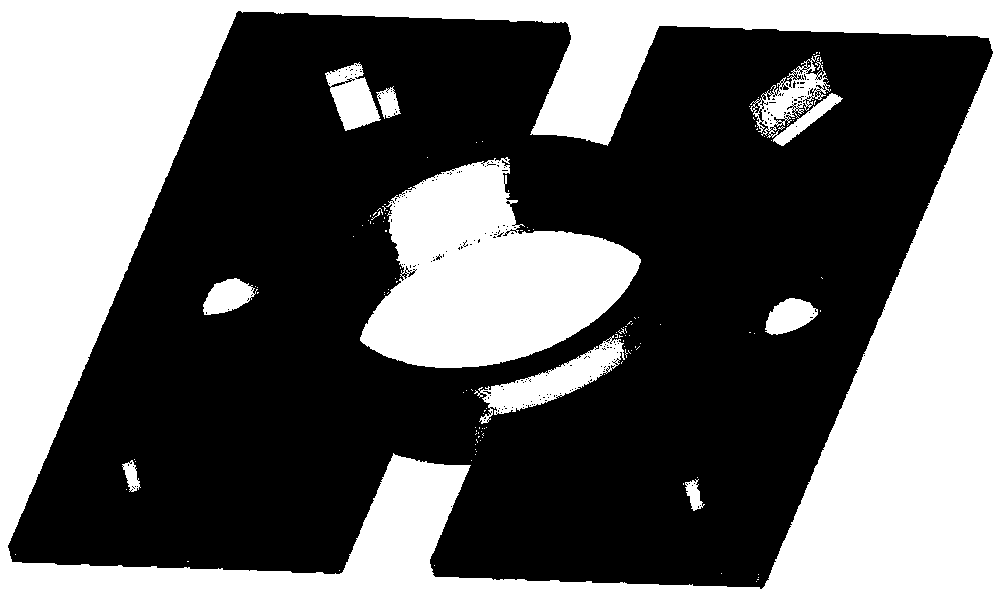

Heat exchanger for waste heat recovery of coal-fired boiler

ActiveCN106016238AStrengthen the degree of disturbanceReduce resistanceFeed-water heatersCounter flowEngineering

The invention discloses a heat exchanger for waste heat recovery of a coal-fired boiler. The design concept combining a section-separated heat transfer enhancement principle and a technology for flexibly adjusting the tube wall temperature through graded water supply is adopted, the heat exchanger is divided into a high-temperature section adopting carbon steel and a low-temperature section adopting ND steel, tube bundles are staggered, media inside and outside tubes are in a counter-flow type, the tube wall temperature of the high-temperature section and the low-temperature section is adjusted precisely in a graded water supply manner, so that the tube wall temperature is higher than the acid dew point temperature of flue gas throughout, and a low-temperature corrosion relieving effect is realized. The technical problems of low heat transfer temperature pressure and serious low-temperature acid-dew-point corrosion in low-temperature flue gas waste heat recovery of the coal-fired boiler are solved very well, by means of combination of section-separated heat transfer enhancement and flexible adjustment of the tube wall temperature through graded water supply, the heat exchange performance and the anti-corrosion effect of the low-temperature heat exchanger are improved obviously, the efficiency and the economical efficiency of the low-temperature flue gas waste heat recovery of the coal-fired boiler are improved substantially, and the heat exchanger has good social and economic benefit and great industrial application and popularization potential.

Owner:苏华建设集团有限公司

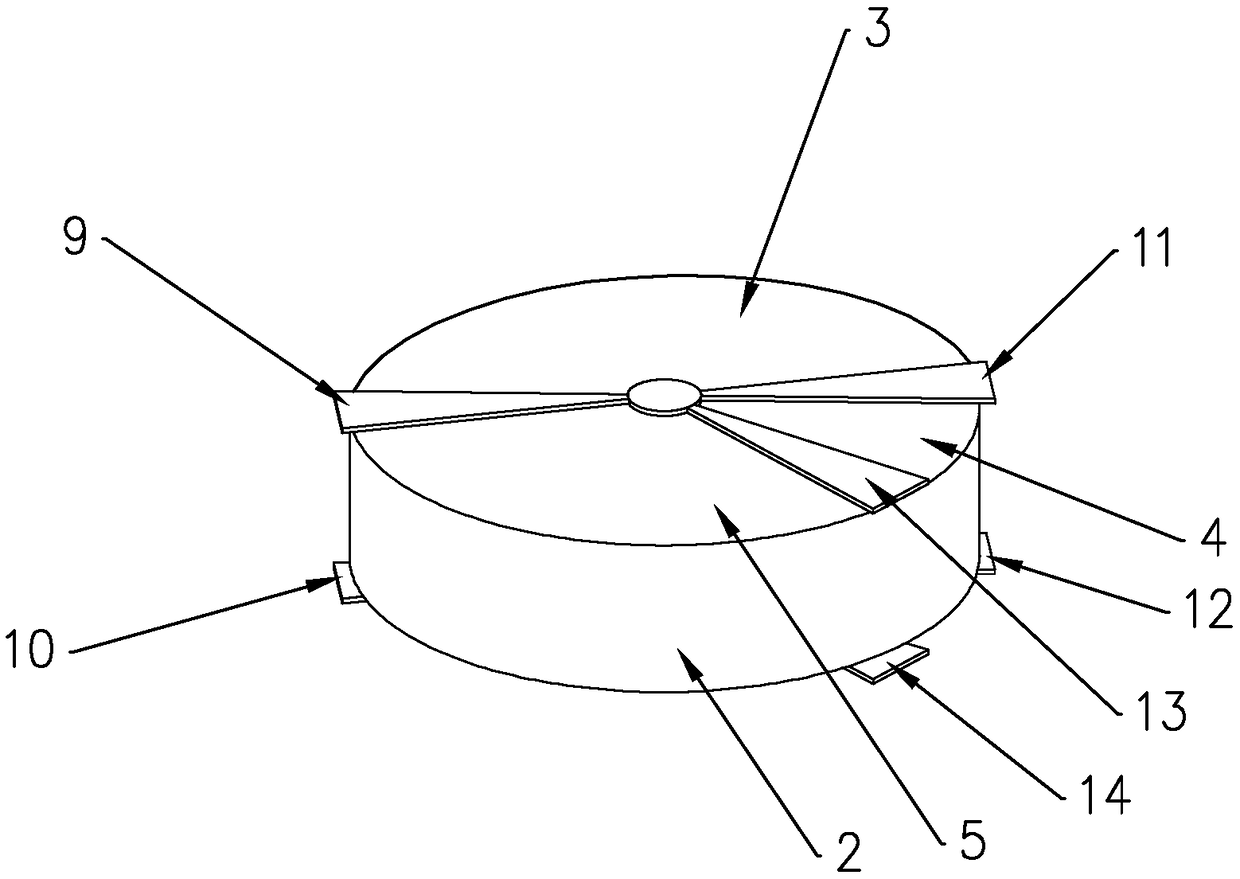

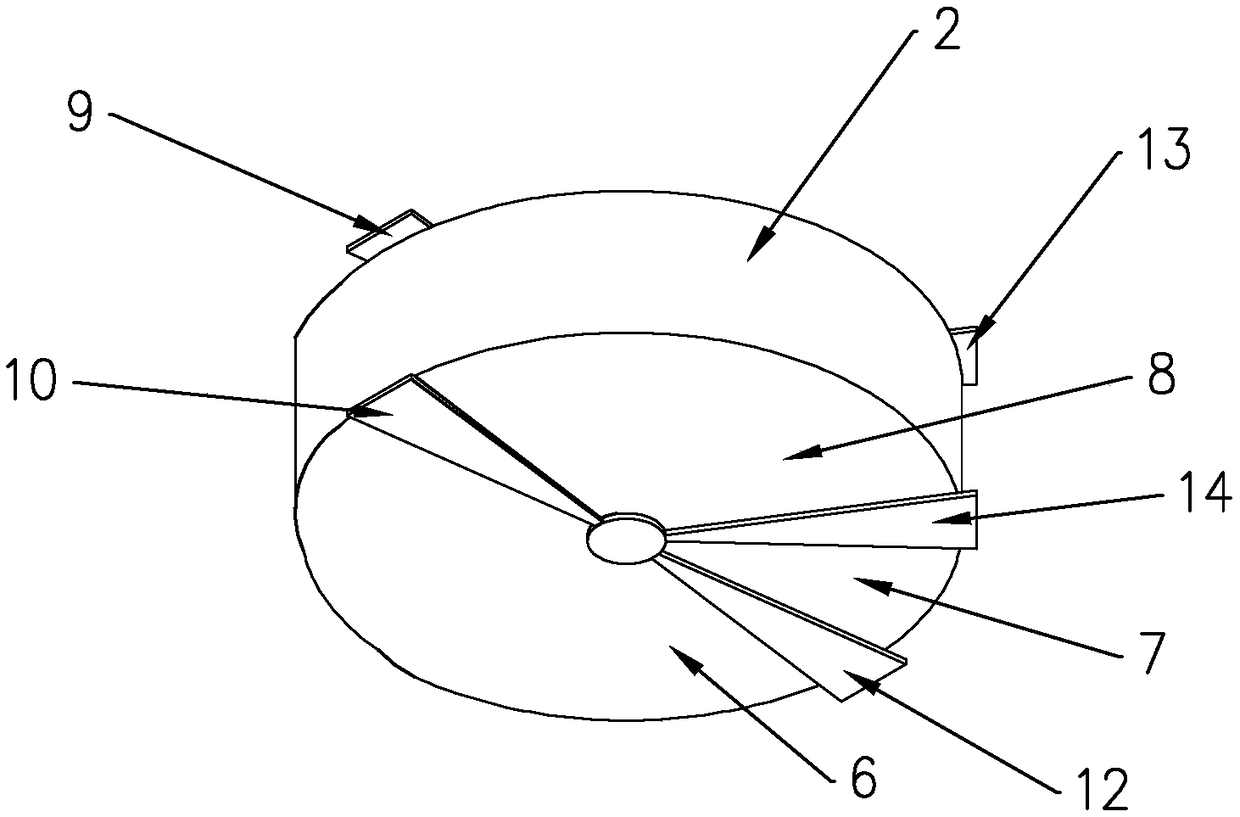

Improved H finned tube used for waste heat recycling

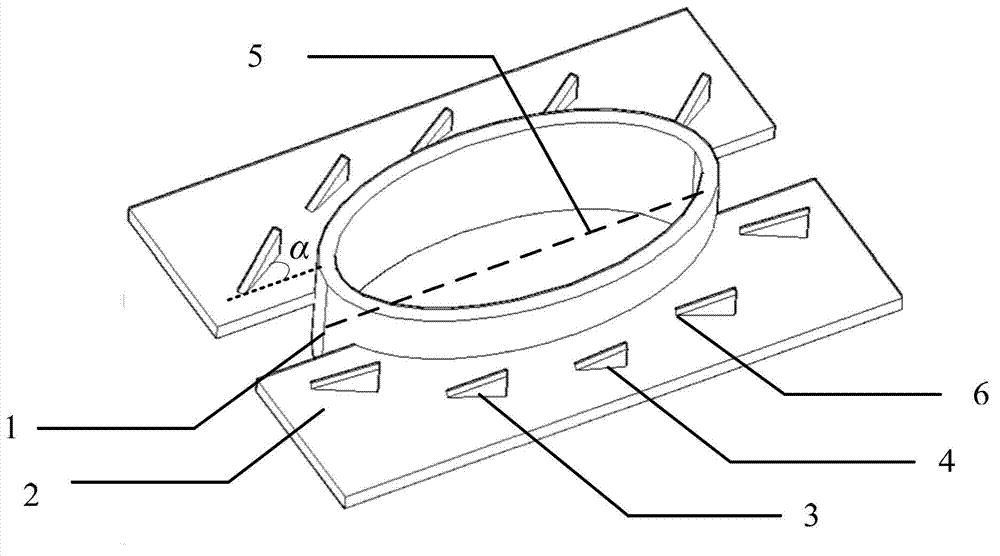

PendingCN109506512AIncreased flow heat transfer coefficientReduce flow pressure lossLaminated elementsHysteresisEngineering

The invention discloses an improved H finned tube used for waste heat recycling. The finned tube comprises a base tube and fin sets; the base tube has a certain length, multiple parallel fin sets arearranged in the axial direction of the base tube and are connected to the outer wall of the base tube, the windward sides of the fin surfaces are provided with flow disturbance rods, spherical protrusion structures are arranged at the positions, on the side of the base tube, of the center positions of the fin surfaces, and a small wing vortex generator is arranged on the leeward sides of the fin surfaces. When smoke flows past, the direction is not changed, the fins with spherical protrusions and the flow disturbance rods can change the airflow motion states, disturbance is intensified, the hysteresis heat layer thickness can be reduced, and the aim of reinforcing heat transfer is achieved to a certain degree.

Owner:DATANG BEIJING ENERGY MANAGEMENT +2

Elliptical tube H-shaped fin heat exchanger for waste heat recovery

ActiveCN103438746BIncrease disturbanceIncrease the principle of enhanced heat transferTubular elementsParticle adhesionWaste heat recovery unit

Owner:XI AN JIAOTONG UNIV

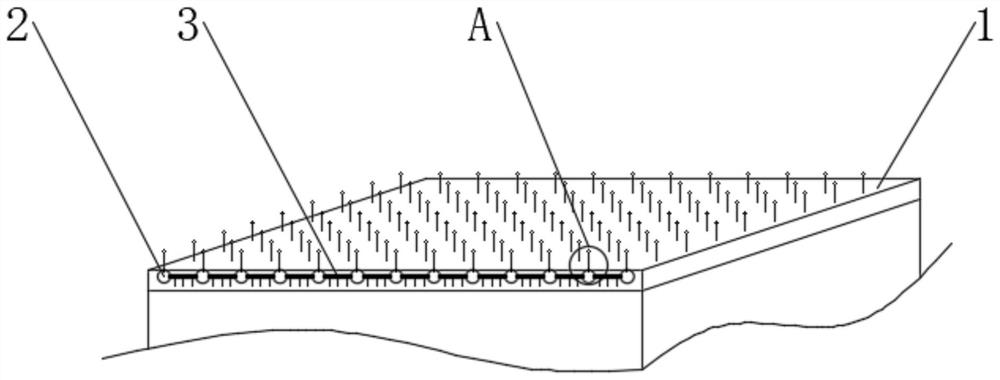

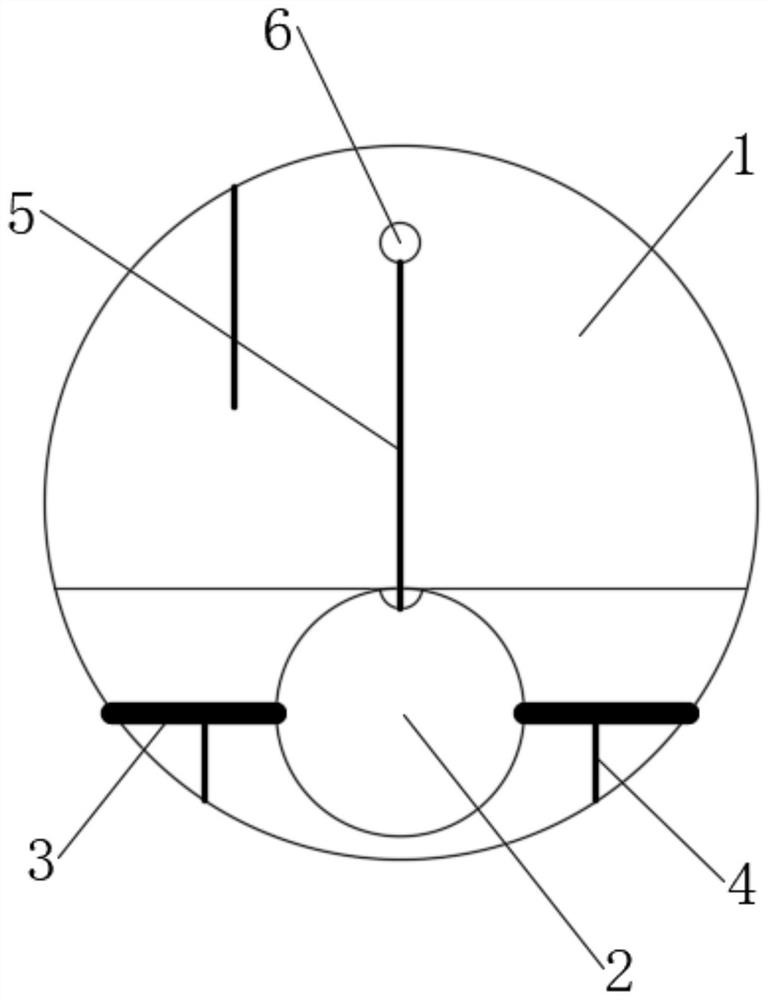

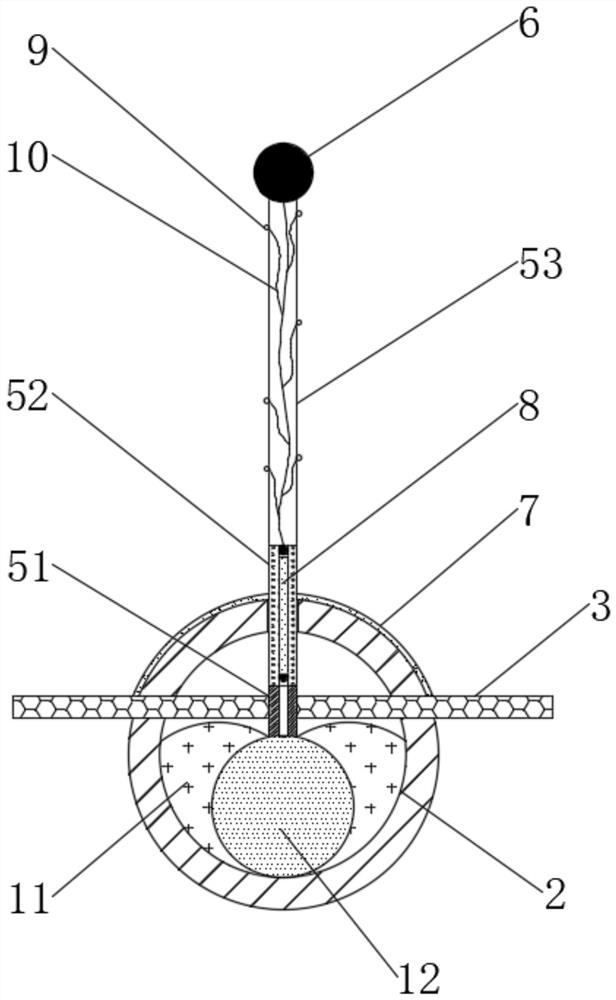

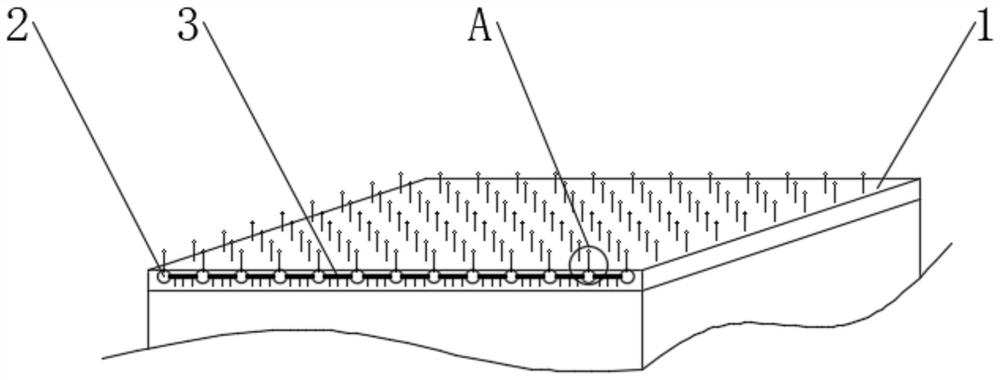

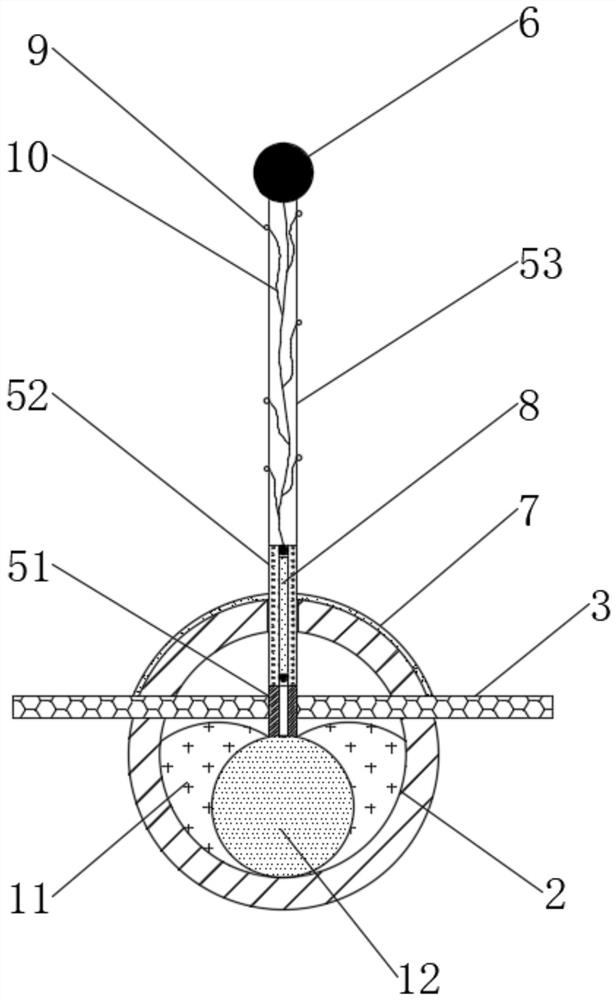

Skin-imitated efficient swinging fluff heat dissipation coating

ActiveCN112029330ASpeed up the flowImprove dust accumulationMagnetic paintsHeat-exchange elementsThermal dilatationThermodynamics

The invention discloses a skin-imitated efficient swinging fluff heat dissipation coating, and belongs to the technical field of coatings. The coating can realize innovative concentration of heat absorbed by a coating body from a system through heat collection balls, then conduct the heat to the outside through a double-effect heat dissipation composite rod, and extrude air supply base balls by utilizing the characteristic that a thermal expansion wrapping sleeve is heated to expand, so that the heat dissipation effect of the coating is improved. Gas in a gas supply base ball is extruded intoa double-effect heat dissipation composite rod, a traction mid-span airbag rod is inflated and expanded, hardening of the traction mid-span airbag rod is promoted to drive the whole double-effect heatdissipation composite rod to stand up, the traction mid-span airbag rod is forced to slowly leak gas to the outside based on the magnetic attraction effect, and on one hand, the traction mid-span airbag rod is promoted to be softened and fall down again. According to the double-effect heat dissipation composite rod, the swing action can be achieved, the dust accumulation phenomenon can be improved, air flowing near the coating body can be accelerated, heat on the double-effect heat dissipation composite rod is taken away from the interior through the air leakage process, and the heat dissipation effect of the coating body is remarkably improved.

Owner:杭州贝赛迪科技有限公司

Biomass granular fuel and preparation method thereof

InactiveCN112111311AReduce porosityImprove molding rateBiofuelsSolid fuelsProcess engineeringEnvironmental engineering

The invention discloses a biomass granular fuel and a preparation method thereof, and relates to the field of development and utilization of waste biomass resources. The biomass granular fuel disclosed by the invention is prepared by the following steps: drying and crushing a biomass raw material to obtain powder, adding the lignin-based binder and the additive into the powder, uniformly stirringby virtue of a stirrer, mechanically compressing, granulating and cooling, thereby obtaining the biomass granular fuel. The lignin-based binder is obtained by adding a polyacrylic acid / urea polymer into a suspension containing lignin particles, adjusting the pH value, stirring, filtering, drying and crushing. According to the biomass granular fuel provided by the invention, by adding the lignin-based binder, the forming rate of the biomass granular fuel is increased, the biomass granular fuel is not easy to break in the transportation process, the combustion speed is stable, slag bonding is not liable to generate in the combustion process, the combustion efficiency is improved, the service life of a combustion device is prolonged, and the environmental pollution is reduced.

Owner:桃江县新辉生物质颗粒有限公司

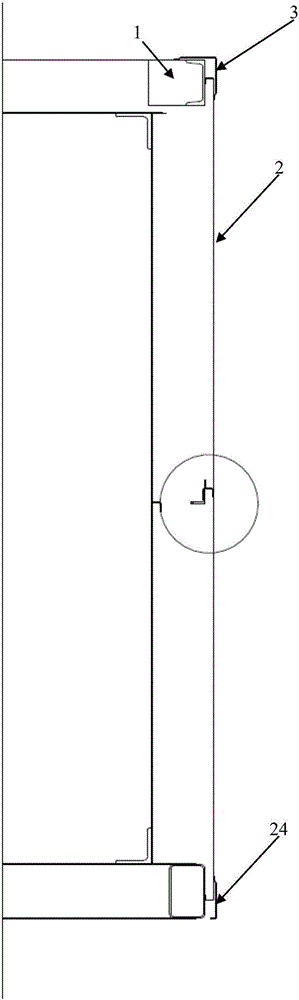

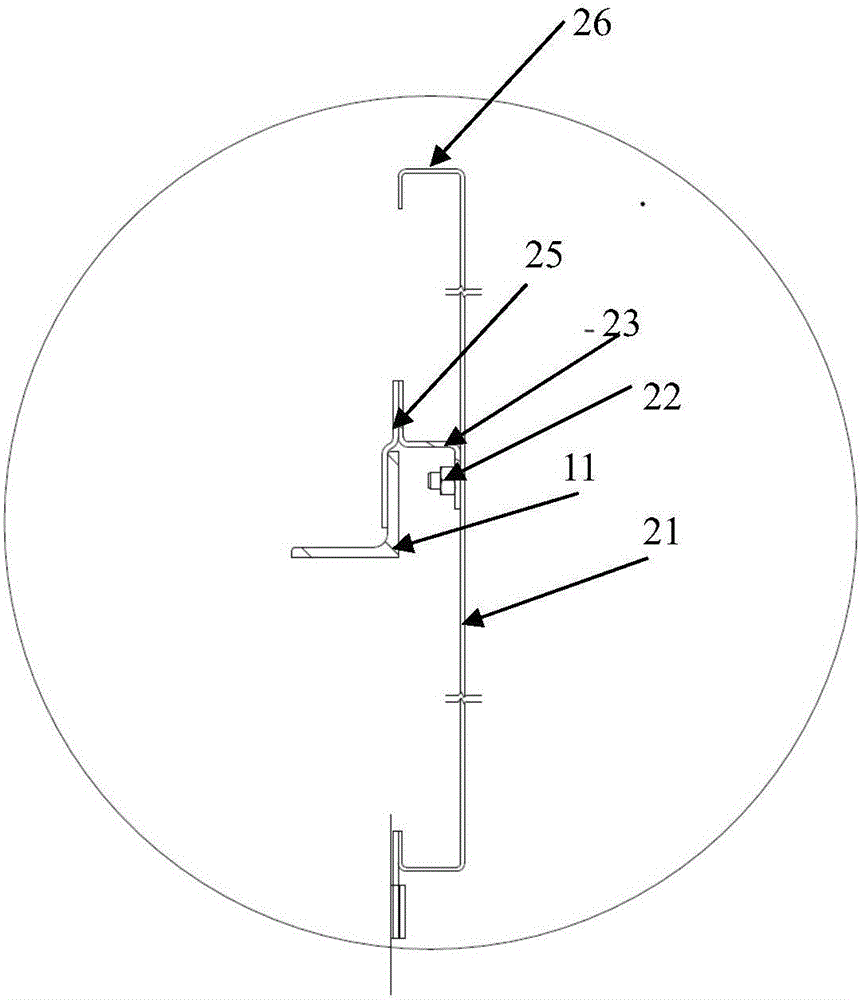

External thermal insulation structure of heating box

The invention discloses an external thermal insulation structure of a heating box. The external thermal insulation structure comprises an inner frame embedded with a thermal insulation layer and outer panels fixedly connected with the inner frame, each outer panel comprises a panel body, a connecting bolt fixedly arranged on the inner surface of the panel body and a support part which is arranged long the transverse direction and longitudinal directions of the panel body and fixedly connected with the panel body through the connecting bolt. According to the external thermal insulation structure, on the premise that the thermal insulation effect is guaranteed, the problem that dust is accumulated and is not prone to cleaning is relieved; due to the fact that the heat radiating areas of the outer panels themselves are small, thermal bridge is reduced, and meanwhile the air heat insulation effect is produced in the cavities of the outer panels; by means of actual measurement, the surface temperature of the heating box adopting the outer panels is about 5 DEG C lower than that of corrugated boards, and the energy can be effectively saved by about 5%.

Owner:AUTOMOTIVE ENG CORP +1

Biomass granular fuel and preparation method thereof

ActiveCN108641773AIncrease the softening temperature of ash accumulationFully contactedBiofuelsSolid fuelsOxygenAlkali metal

The invention discloses a biomass granular fuel. The fuel comprises a biomass raw material and an additive, wherein the additive is a mixture of chitosan, calcium oxide and urea, and a weight of the additive is 0.5-4.8% of a weight of the biomass raw material. According to the fuel disclosed by the invention, a certain amount of chitosan, calcium oxide and urea are added into the biomass raw material as the additive, so that alkali metal elements in the biomass granular fuel can be fixed, and the problems of dust accumulation and slagging caused by alkali metals contained in the biomass granular fuel can be effectively improved; and addition of the chitosan, the calcium oxide and the urea can increase a contact area of the biomass granular fuel and oxygen, make a combustion reaction more sufficient, and prolong burning time, thereby improving burning efficiency. The invention also provides a preparation method of the biomass granular fuel.

Owner:湖北和泰生物能源有限公司

A kind of biomass particle fuel and preparation method thereof

ActiveCN108641773BIncrease the softening temperature of ash accumulationFully contactedBiofuelsSolid fuelsEngineeringEnvironmental engineering

Owner:湖北和泰生物能源有限公司

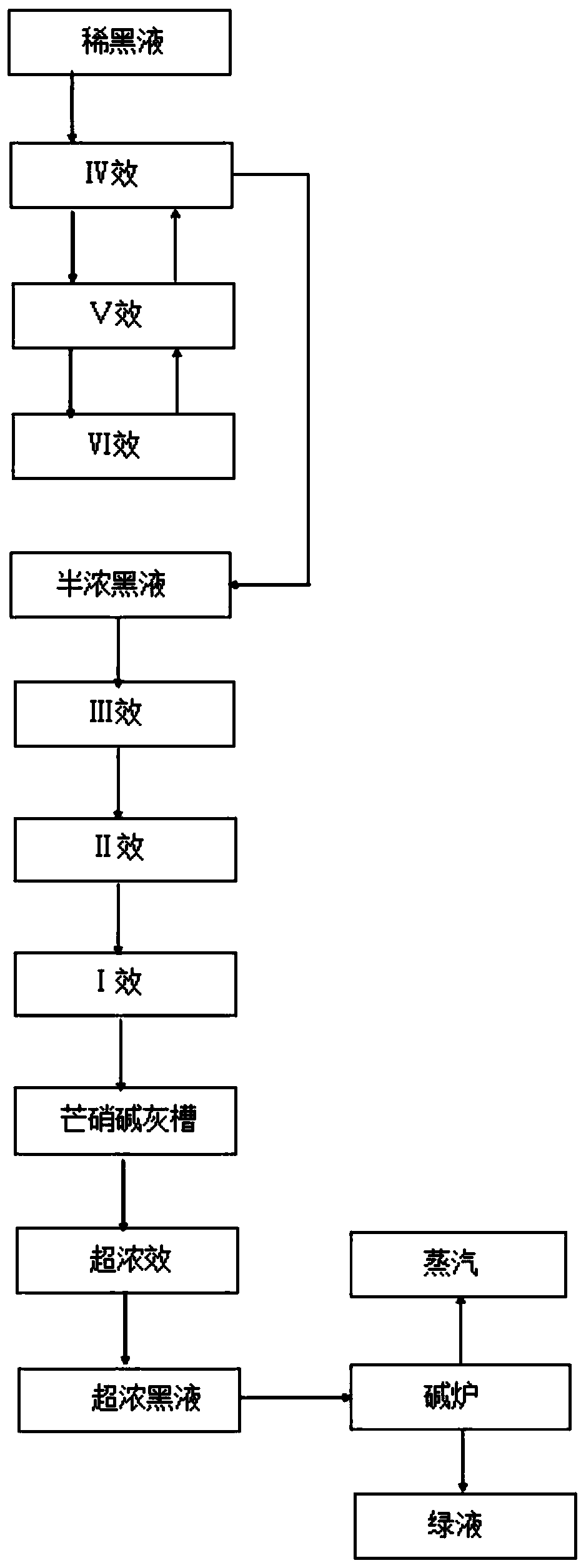

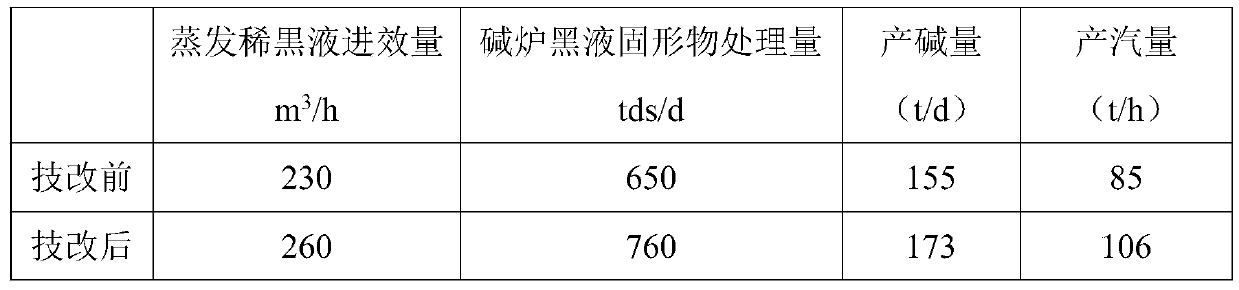

Production method for improving productivity of alkaline furnace

InactiveCN111017959AWell mixedImprove heat transfer coefficientAir supply regulationAlkali metal hydroxidesBlack liquorAir volume

The invention discloses a production method for improving productivity of an alkaline furnace. The method comprises the following steps: (1) evaporating and concentrating of black liquor, wherein coniferous wood dissolving pulp black liquor is evaporated and concentrated by using I effect, II effect, III effect, IV effect, V effect, VI effect and super-concentration effect, so that the concentration of the treated black liquor is over 72%; (2) air volume and air pressure proportioning, wherein the primary air volume is 40000 Nm<3> / h, the primary air pressure is 1000 pa, the secondary air volume is 45000 Nm<3> / h, the secondary air pressure is 1200 pa, the tertiary air volume is 32000 Nm<3> / h, and the tertiary air pressure is 1800 pa; and (3) jet combustion, wherein black liquor jet combustion is performed by setting the aperture of a black liquor spray gun at 20 mm and setting the jet pressure at 0.08 Mpa. According to the invention, the problem of insufficient productivity of an alkalirecovery system is solved, and through adjustment of the production process, the black liquor treatment capacity is effectively improved, and the alkali yield and the steam yield are increased.

Owner:FUJIAN QINGSHAN PAPER INDUSTRY CO LTD

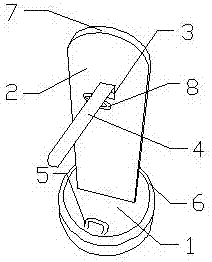

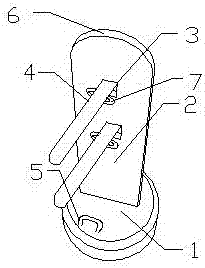

Circular arc-shaped safety protection fence with handles for reducer

InactiveCN107304964AFirmly connectedImprove wear resistanceEngineering safety devicesSurface layerWear resistant

The invention relates to a circular arc-shaped safety protection fence with handles for a reducer. The safety protection fence comprises a base (1), a protective rod (2) and a connecting rod (4), a non-stick layer is arranged on the surface of the base (1), a wear-resistant layer (2.1) is arranged on the surface of the protective rod (2), a circular arc chamfer (6) is arranged on the upper edge of the base (1), a circular arc (7) is arranged at the top of the protective rod (2), and the connecting rod (4) is sleeved with a protective sleeve (8). According to the circular arc-shaped safety protection fence with the handles for the reducer, convenience is provided for carrying and moving the safety protection fence by workers, a lot of manpower and material resources are saved, a good protection effect on the workers is achieved, the workers are not prone to being bruised, the adjacent protection fences are connected more firmly because the connecting rod is not prone to slide, wear resistance of the protective rod is enhanced, the service time is prolonged, and the surface of the base is not prone to dust accumulation and is convenient to clean.

Owner:江阴市新城东达尔机械厂

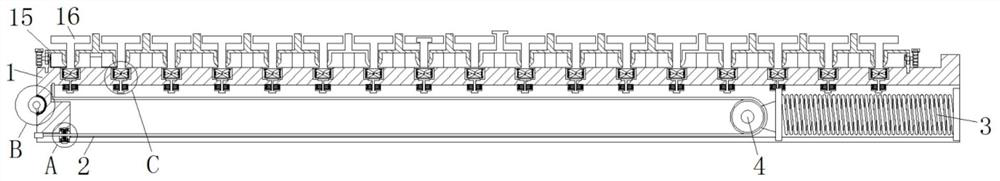

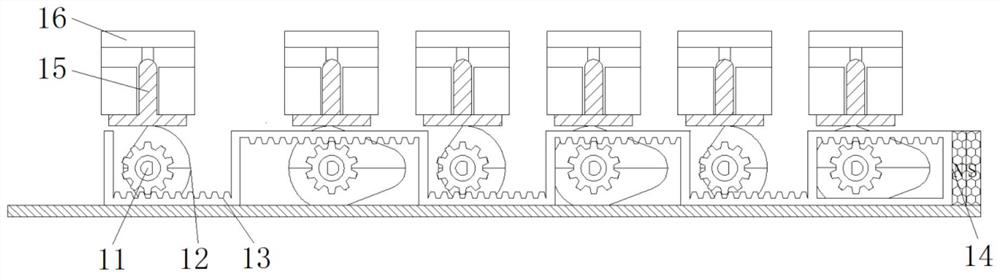

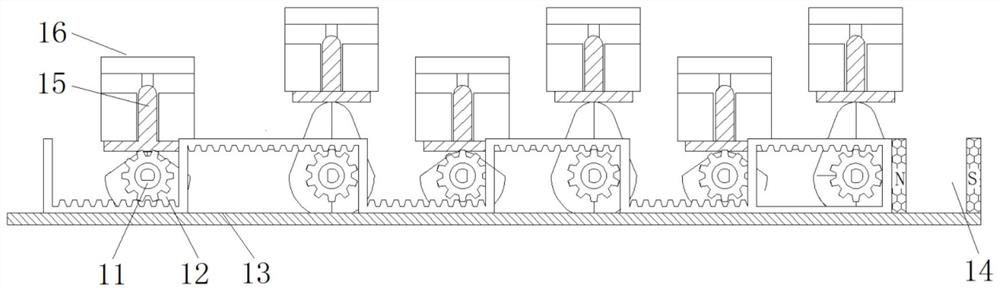

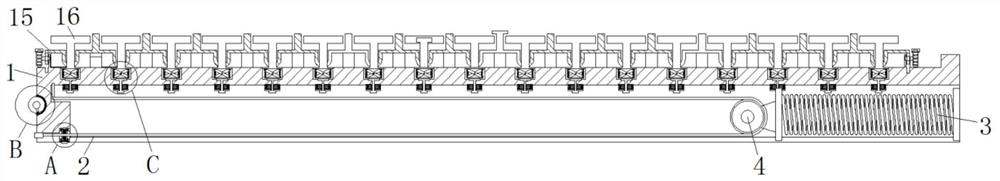

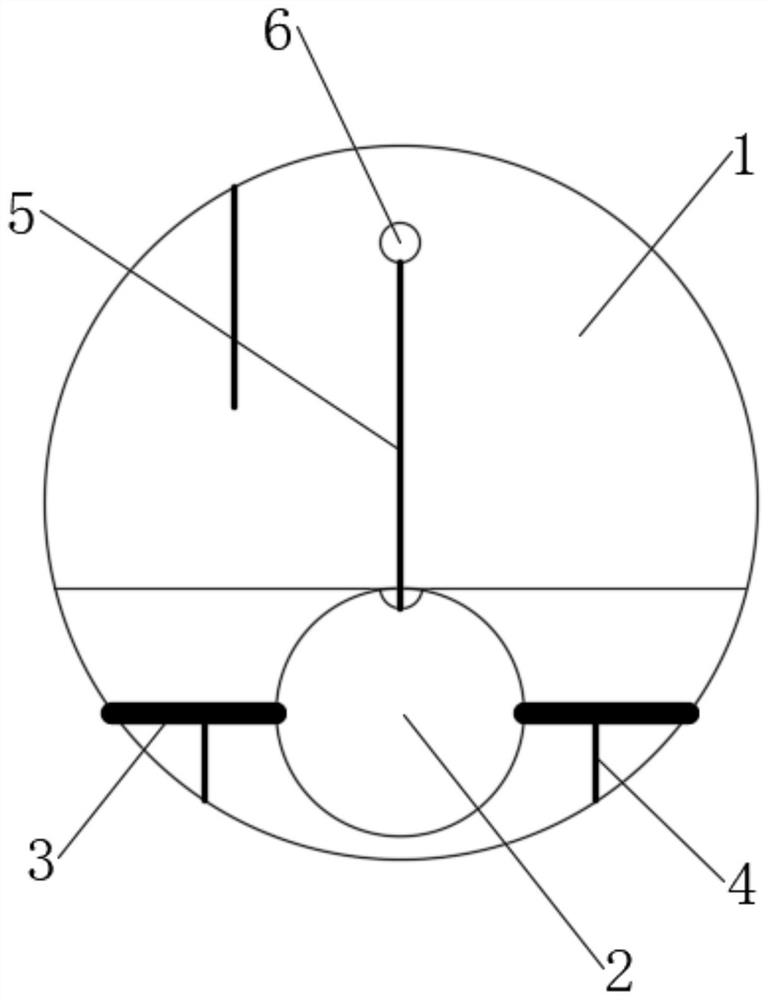

A keyboard that is easy to clean and intelligently adjusts pressing force

ActiveCN112130671BEasy to cleanIntelligent adjustment of pressureInput/output for user-computer interactionKey pressingUser needs

The invention relates to the technical field of computer input devices, and discloses a keyboard that is convenient for cleaning and intelligently adjusts the pressing force, including a casing, the bottom of the casing is fixedly connected with a keyboard wire, and the right end of the bottom of the casing is passed through a return spring A support is elastically connected, the left end of the support is rotatably connected with a pulley, the bottom of the housing is rotatably connected with a screw, and the external movement of the screw is connected with a clamp block, and the end of the clamp block away from the keyboard cable is elastically connected There is a spring one, and the left end of the housing is rotatably connected with a turntable. The keyboard, which is easy to clean and intelligently adjusts the pressing force, adjusts the key pressure according to the needs of the user, enhances the user experience, adjusts the extension length of the keyboard line according to the actual use environment, facilitates the adjustment of the length of the keyboard line, and prevents the keyboard line from being too long. Winding, easy to clean the bottom groove of the keyboard, avoiding the waste of time caused by dismantling all the keys.

Owner:苏州工业园区捷讯特精工模塑有限公司

Gasification method of carbon-containing solid raw material and used reactor

ActiveCN102041106BEnsure safetyGuaranteed long-term operationEnergy inputCombustible gas productionSyngasSlag

The invention relates to a gasification method of a carbon-containing solid raw material and a used reactor. The gasification method is characterized by comprising the following steps of: reacting the carbon-containing solid raw material with oxygen in a reactor unit so as to generate synthesis gas, wherein ash flows downwards into a slag pool at the lower end of a gasification reactor in the slag form under the action of gravity force; allowing high-temperature synthesis gas which entrains molten ash residues to rise to a chill zone in the gasification reactor, injecting steam or / and water into the chill zone by using chilling equipment and chilling the high-temperature synthesis gas so as to freeze the molten ash residues entrained in the high-temperature synthesis gas into solid dust; introducing the synthesis gas which entrains the chilled solid dust into a dust removing unit so as to remove dust entrained in the synthesis gas; and introducing the synthesis gas into a waste boiler unit and generating steam by using process waste heat of the synthesis gas. The reactor provided by the invention isolates a gasification furnace from the waste boiler unit through respective shell and the dust removing unit is arranged between the gasification furnace and the waste boiler unit. The equipment has low wear rate and can run for a long time.

Owner:CHINA PETROCHEMICAL CORP +2

Keyboard convenient to clean and capable of intelligently adjusting pressing force

ActiveCN112130671AEasy to cleanIntelligent adjustment of pressureInput/output for user-computer interactionKey pressingEngineering

The invention belongs to the technical field of computer input equipment and discloses a keyboard convenient to clean and capable of intelligently adjusting pressing force. The keyboard comprises a shell; the bottom of the shell is fixedly connected with a keyboard wire; the right end of the bottom of the shell is elastically connected with a support through a return spring; the left end of the support is rotatably connected with a pulley; a screw rod is rotatably connected to the bottom of the shell; a clamping block is movably connected to the outer portion of the screw rod; a first spring is elastically connected to the end, away from the keyboard wire, of the clamping block; and a rotary disc is rotatably connected to the left end of the shell. According to the keyboard convenient to clean and capable of intelligently adjusting the pressing force, the key pressure is adjusted according to the requirements of a user, the user experience is enhanced, the extending length of the keyboard wire is adjusted according to the actual use environment, the length of the keyboard wire is conveniently adjusted, the keyboard wire is prevented from being excessively long and intertwined, andaccumulated dust in grooves in the bottom of the keyboard is conveniently cleaned; time waste caused by dismounting all the keys is avoided.

Owner:苏州工业园区捷讯特精工模塑有限公司

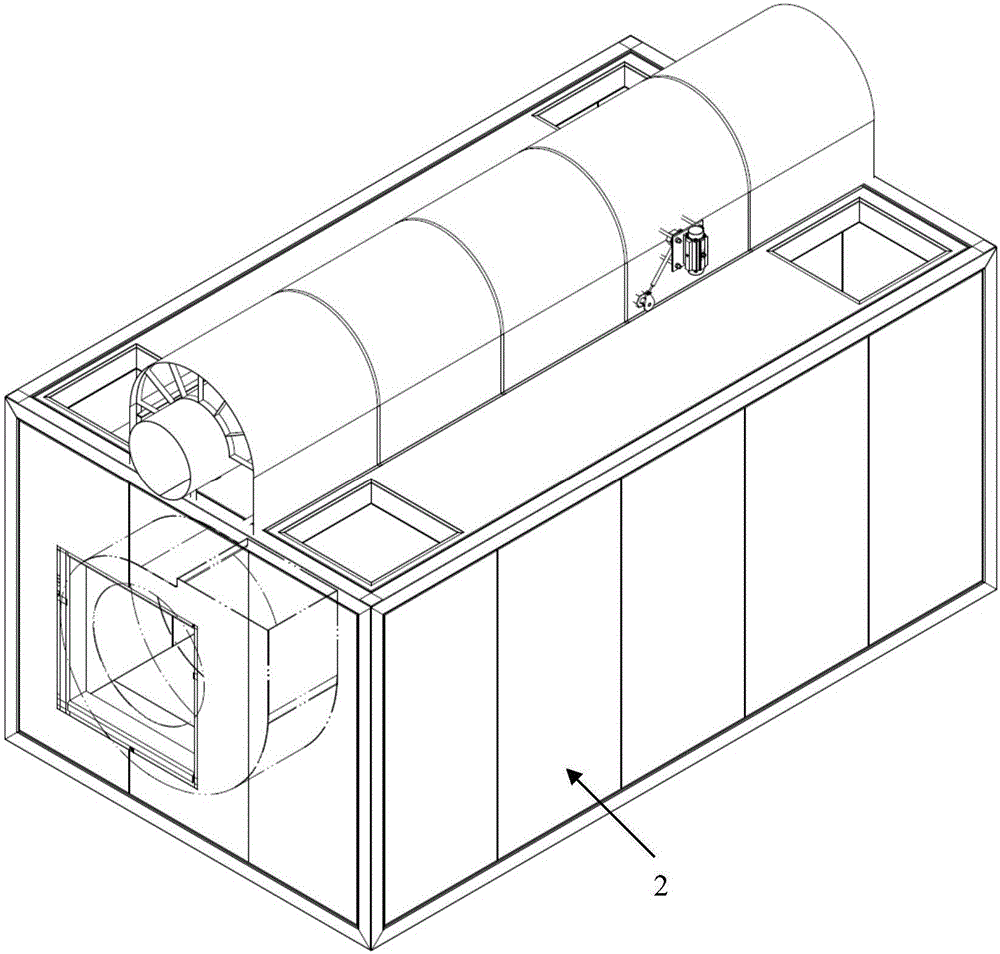

Pollutant removal structure and combustion device suitable for domestic waste pyrolysis gasification gas

ActiveCN108061303BAvoid Synthetic FacilitationReduce contentIncinerator apparatusCombustionEnvironmental engineering

The invention belongs to the relative technical field of domestic waste incineration and pollutant control, and discloses a pollutant removal structure suitable for domestic-waste-pyrolyzed gasification gas and a combustion device. The pollutant removal structure comprises a furnace body, and a chamber is formed in the furnace body. A support plate is arranged in the chamber, the chamber is divided into an upper chamber and a lower chamber by the support plate, and the upper chamber communicates with the lower chamber. The pollutant removal structure further comprises a calcium-based ejector and a primary air pipe, wherein the primary air pipe is arranged on the furnace body and communicates with the lower chamber; the calcium-based ejector is adjacent to the primary air pipe and is used for ejecting calcium-based materials into the primary air pipe; and the primary air pipe is used for enabling the domestic-waste-pyrolyzed gasification gas and primary air to enter the lower chamber and to be desulfurized and dechlorinated at above 850 DEG C. The pollutant removal structure reduces dioxin emission, solves the problems of contamination and dust stratification, and has the advantagesof simple structure and high flexibility.

Owner:HUAZHONG UNIV OF SCI & TECH

Ironing worktable for electric iron

Owner:湖州雷暴电子科技有限公司

A skin-like oscillating hair heat dissipation coating

ActiveCN112029330BSpeed up the flowImprove dust accumulationMagnetic paintsHeat-exchange elementsThermal dilatationEngineering

The invention discloses a skin-like oscillating fluff heat-dissipating coating, which belongs to the technical field of coatings, and can innovatively concentrate the heat absorbed by the coating body from the system through a heat-collecting ball, and then pass through a double-effect heat-dissipating composite rod Conduction to the outside world, using the characteristics of heat expansion of the thermal expansion wrap to squeeze the air-supply base ball, extrude the gas in the air-supply base ball into the double-effect heat dissipation composite rod, and carry out the process of pulling the mid-span airbag rod Inflate and expand, prompting it to "harden" and drive the double-effect heat dissipation composite rod to "stand up" as a whole, and force the pulling mid-span airbag rod to slowly leak air to the outside based on the magnetic attraction effect, on the one hand, it promotes the pulling mid-span airbag rod to "soften" "Falling down again can realize the swing action to improve the dust accumulation phenomenon, and can accelerate the air flow near the coating body. The heat dissipation effect of the layer body.

Owner:杭州贝赛迪科技有限公司

A liquid decoker

InactiveCN102329676BReduce dust accumulationHas cleaning effectFuel additivesBULK ACTIVE INGREDIENTOxygen

The invention discloses a liquid decoking agent, which belongs to the technical field of clean coal combustion. The main active ingredients are organic surfactants and nitrates. Organic surfactants under high temperature conditions, on the one hand, the organic polymer compounds have a decontamination effect; on the other hand, the organic polymer compounds react under high temperature conditions to produce a large number of bubbles, which will promote the loosening of the coke. On the one hand, nitrate can “micro-explode” at high temperature and release oxygen, which can ensure continuous release of oxygen from low temperature to high temperature, promote the loosening of ash and carbon deposits in different parts, and help pulverized coal to burn more efficiently. On the other hand, metal ions in nitrate can promote the conversion of low-melting-point compounds in the coke layer into loose high-melting-point compounds, which can not only help to remove the coke layer, but also prevent high-temperature corrosion.

Owner:SNTO TECH GRP

Coal burning hot-blast stove

InactiveCN1945182BImprove dust accumulationImprove heat utilizationAir heatersHeating arrangementSlagEngineering

The present invention belongs to the field of thermal equipment technology, and is especially coal burning hot blast stove. The coal burning hot blast stove has one casing, one blower in the upper part of the casing, one burning energy changer comprising burning hearth and heat exchanger in the middle part, one transverse flue connected between the burning energy changer and the chimney and with soot door, vertical cooling fins outside the burning energy changer and the flue, one hot blast cavity formed between the casing and the burning energy changer and the flue, one coal feeding port and one cleanout door below the burning energy changer. The burning energy changer is heated by flame under it, and the heat in the burning energy changer and the flue are carried out by the air from the blower. The coal burning hot blast stove has convenient soot and slag elimination and high heat efficiency.

Owner:康秉荣

A method for determining the inlet parameters of a selective catalytic reduction denitrification device

ActiveCN103926833BImprove denitrification efficiencyReduce escape rateAdaptive controlBoiler furnaceFlue gas

The invention relates to a method for determining the inlet parameter of an SCR denitration device. According to the method, a boiler furnace, a horizontal flue and a tail portion flue are used as calculating objects, numerical simulation of the total-system combustion, heat transfer and flowing process is conducted by the aid of Fluent software, the flue gas parameters of an economizer outlet, namely an inlet of the SCR denitration device under different working conditions are obtained, and the flue gas parameters relate to velocity distribution, temperature distribution and smoke component concentration distribution; according to the whole system from the boiler furnace, the horizontal flue and the tail portion flue (to the economizer outlet), numerical simulation of the combustion, heat transfer and flowing process is conducted, movement of solid-phase particles is also taken into account, the solid-phase particle parameters of the economizer outlet, namely the inlet of the SCR denitration device under different working conditions are obtained, the problems that the design calculation and engineering actual deviation of the SCR denitration device is too big due to the fact that the inlet flue gas parameter cannot be reasonably set traditionally, and catalyst abrasion and dust accumulation can be caused for giving too little care to the movement of solid-phase particles are solved, hence, the denitration efficiency of an SCR reactor can be effectively improved, and the service life of catalysts is prolonged.

Owner:SOUTHEAST UNIV

Wear-resistant smooth circular arc-shaped safety protection device

The invention relates to a wear-resistant smooth circular arc-shaped safety protection device. The safety protection device comprises a base (1), a protective rod (2) and connecting rods (4), two sides of the protective rod (2) are each arranged with a handle arranged on the base (1), the connecting rods (4) are sleeved with protective sleeves (7), a wear-resistant layer (2.1) is arranged on the surface of the protective rod (2), and a non-stick layer is arranged on the surface of the base (1). According to the wear-resistant smooth circular arc-shaped safety protection device, the adjacent protective fences are connected more firmly and more stably, the connecting rods are not easy to slide, convenience is provided for carrying and moving the safety protection device by workers, a lot of manpower and material resources are saved, a good protection effect on the workers is achieved, the workers are not prone to being bruised, wear-resistance of the protective rod is enhanced and the service time is prolonged after the wear-resistant layer is arranged, and the surface of the base is not prone to dust accumulation and is convenient to clean.

Owner:江阴市新城东达尔机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com