A method for determining the inlet parameters of a selective catalytic reduction denitrification device

A determination method and denitration technology, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems of not considering catalyst wear and fouling, large deviation of SCR reactor, etc., to meet the requirements of flow field uniformity, reduce Ammonia slip rate, the effect of improving denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

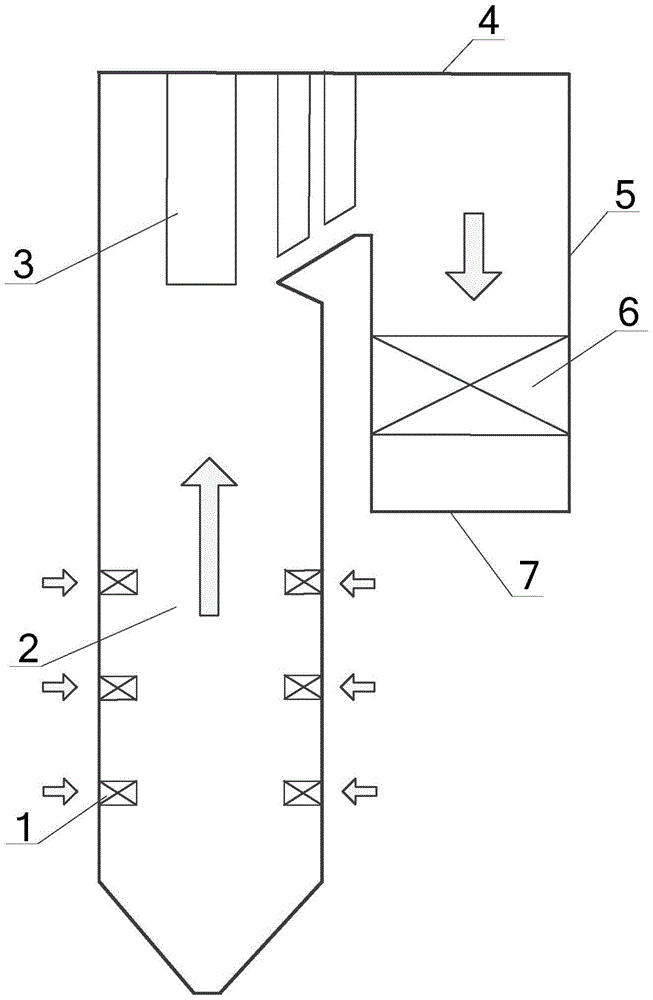

[0024] Described method comprises the following steps:

[0025] 1) According to the structure and size of the actual operating boiler equipment, use Gambit software to establish a three-dimensional physical model of the whole system including the boiler furnace, horizontal flue and tail flue (to the outlet of the economizer), and set the inlet of the burner and the outlet of the economizer is the entrance boundary and exit boundary, and divides the exit boundary into several sub-regions;

[0026] 2) Using Fluent software, taking the inlet conditions of the actual operating equipment as the inlet boundary conditions of the physical model, using the k-ε turbulence model and discrete phase model that can be realized to calculate the combustion process of pulverized coal in the furnace under different working conditions, and the flue gas in the boiler The heat transfer and flow process of the furnace, horizontal flue and tail flue, and the flue gas composition (NOx, O 2 and unbur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com