Gasification method of carbon-containing solid raw material and used reactor

A gasification reactor and oxidation reaction technology, which is used in the manufacture of combustible gas, petroleum industry, energy input, etc., can solve the problems of unsafe operation of downstream devices and equipment, easily damaged waste boilers, and high temperature of synthesis gas discharged from the gasifier. , to achieve the effect of ensuring long-term operation, ensuring continuity and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

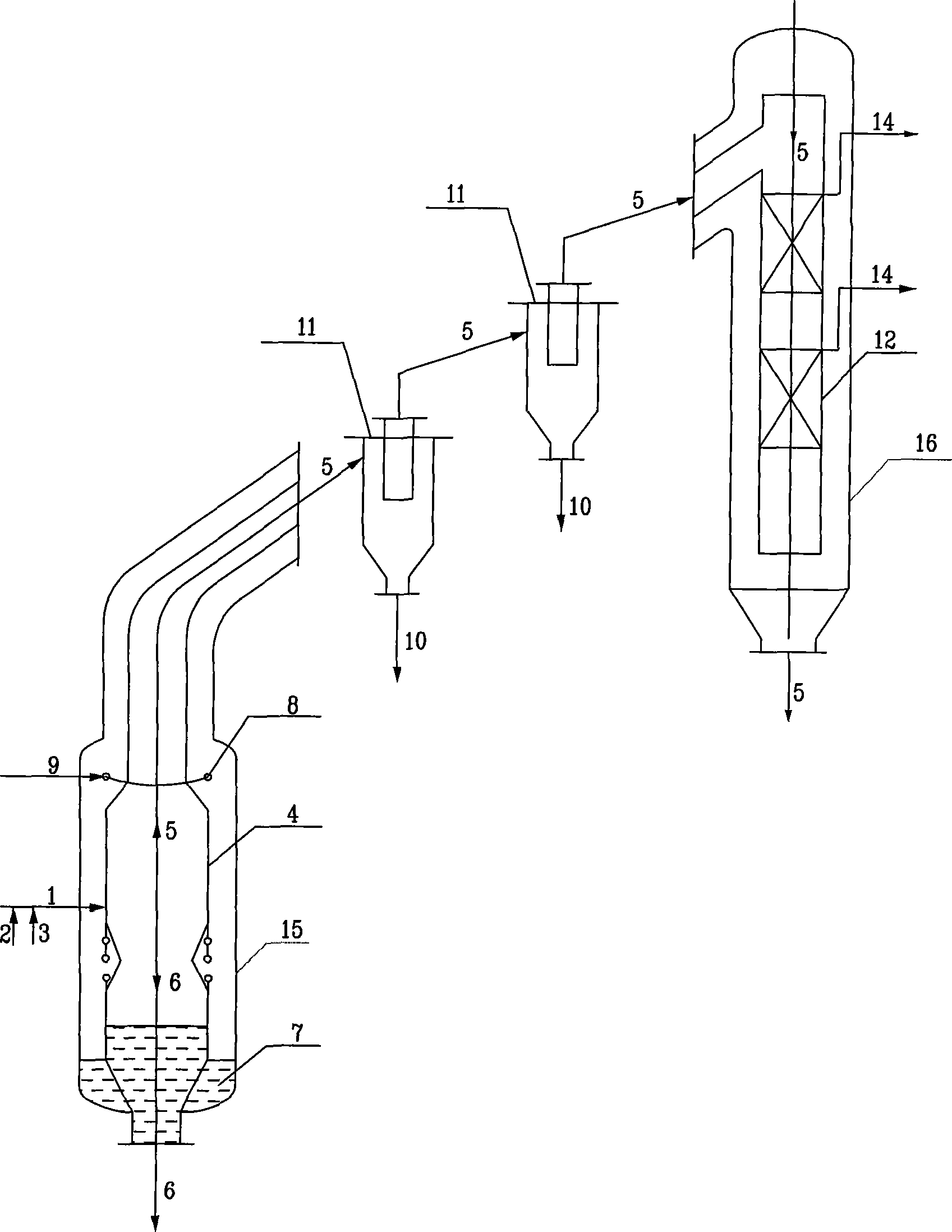

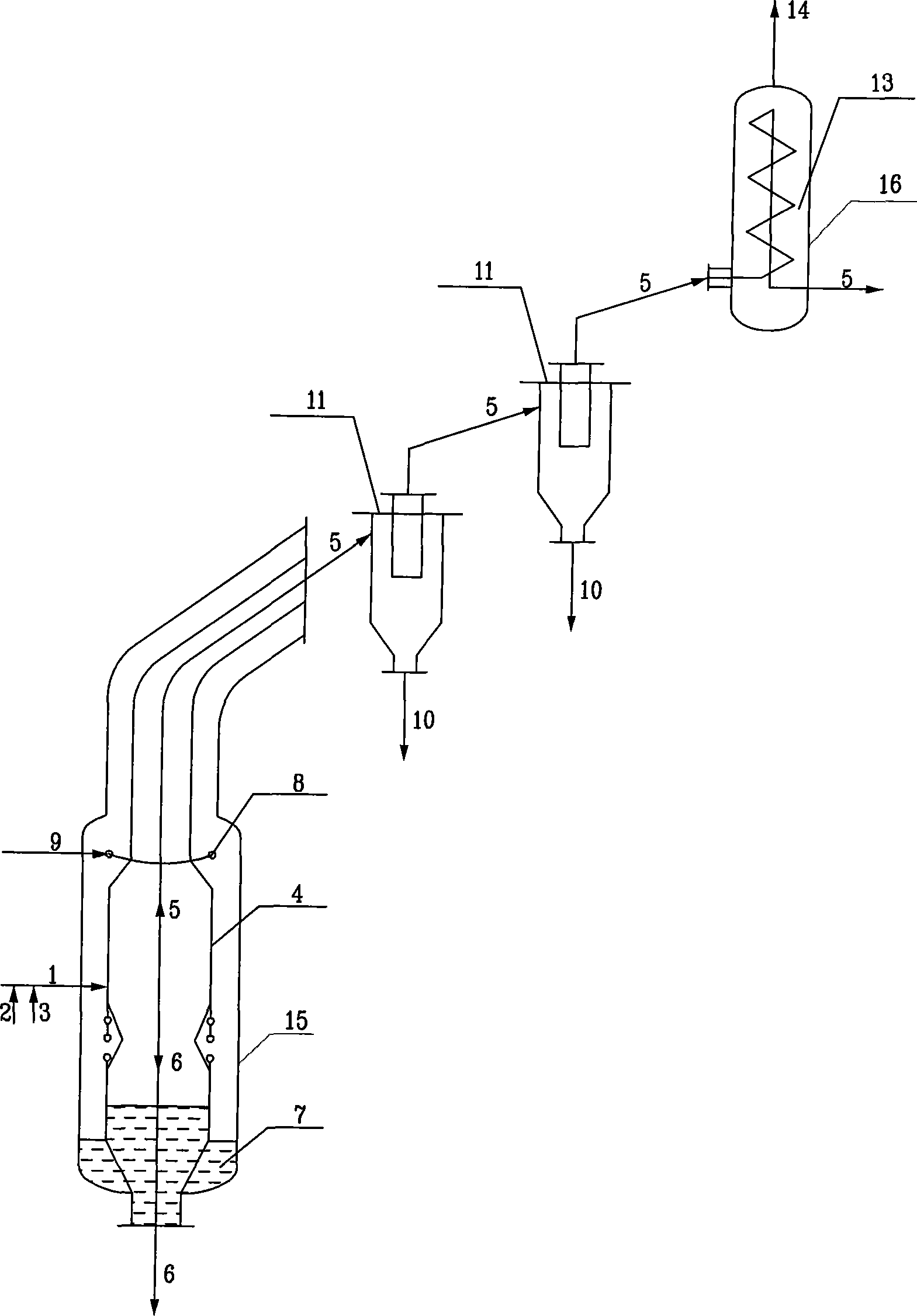

[0027] Such as figure 1 and figure 2 As shown, the gasification reactor for the carbonaceous solid raw material includes a reactor unit 4, a slag pool 7 and a quenching zone, a dust removal unit 11 and a waste pot unit; wherein, the reactor unit 4, the slag pool 7 and the quenching zone It is arranged in the first pressure vessel shell 15 , the waste boiler unit is set in the second pressure vessel shell 16 , and the dust removal unit is located downstream of the first pressure vessel shell 15 and upstream of the second pressure vessel shell 16 .

[0028] Such as figure 1 As shown, a carbon-containing solid feedstock 2 and an oxygen-containing gas 3 are fed into a reactor unit 4 through a burner 1 . In the reactor unit 4, a carbon-containing solid feedstock 2 is subjected to a non-catalytic partial oxidation reaction with an oxygen-contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com