Improved H finned tube used for waste heat recycling

A technology of waste heat recovery and finned tubes, applied in heat exchange and heating equipment, improving the field of H-shaped finned tubes, achieving the effects of reduced flow pressure loss and improved convective heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. The following examples are helpful for those skilled in the art to better understand the present invention, but do not limit the present invention in any form. And it should be pointed out that for those skilled in the art of research, improvements can be made on the basis of the concept of the present invention, which all belong to the protection scope of the present invention.

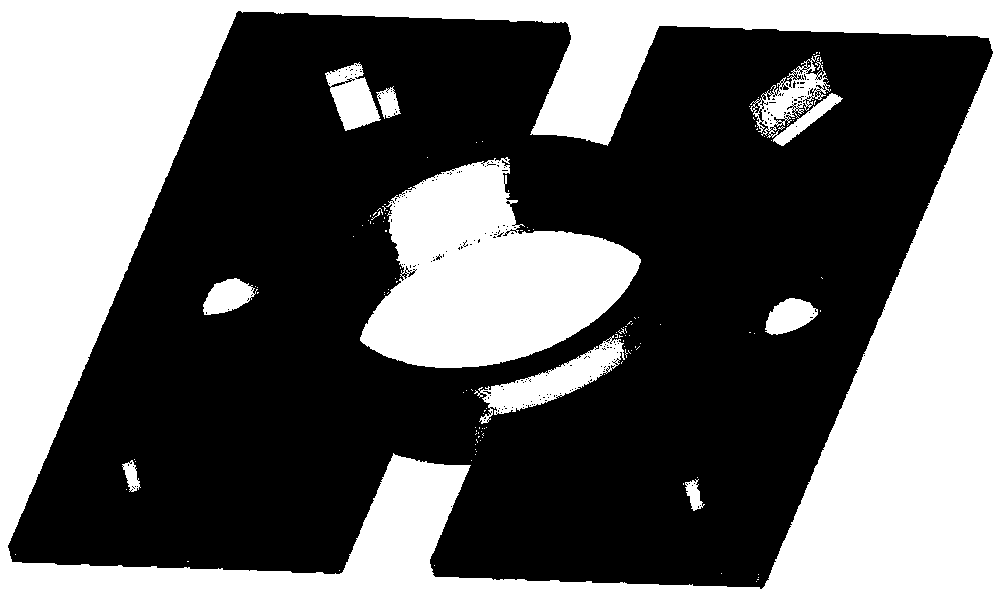

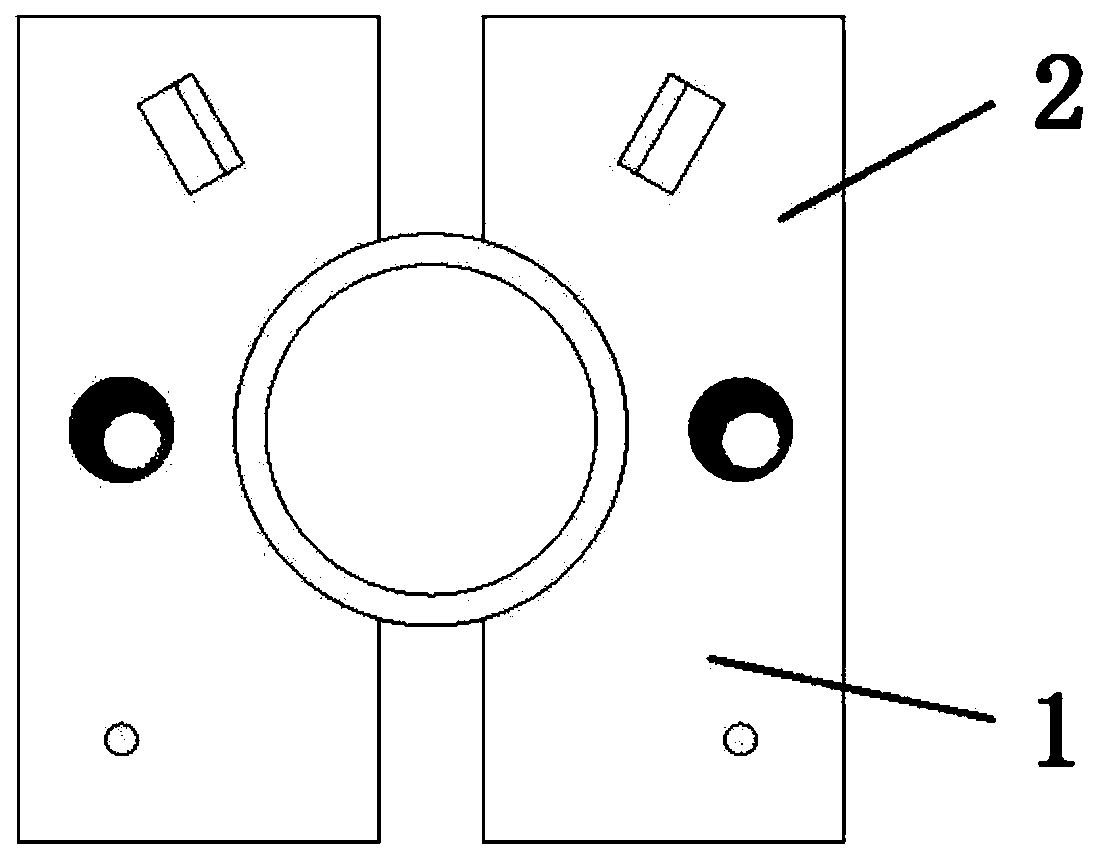

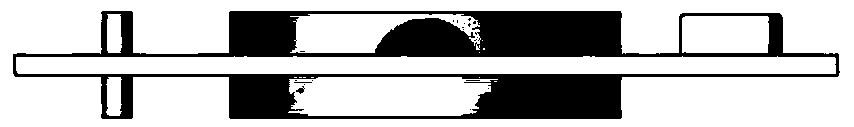

[0015] Figure 1-3 It is a structural schematic diagram of the present invention, including a circular base tube and a pair of fins.

[0016] As shown in the figure, a structurally improved H-shaped finned tube includes a base tube and a fin group. There is a flowing heat exchange working medium inside the base tube, which is generally liquid, and its heat conduction capacity is greater than that of the fluid outside the fins. The fin group includes a group of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com