Photothermal heat exchanger tube bundle supporting structure combined by baffle plates and longitudinal flow grid frames

A support structure and baffle technology, applied to solar collectors, heat exchanger shells, heat exchange equipment, etc. that use working fluids, can solve problems such as the inability to meet the maximum flow resistance of heat exchange tube bundles at the same time, and achieve heat exchange The effect of increasing the coefficient, reducing the flow resistance, and reducing the flow resistance on the shell side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

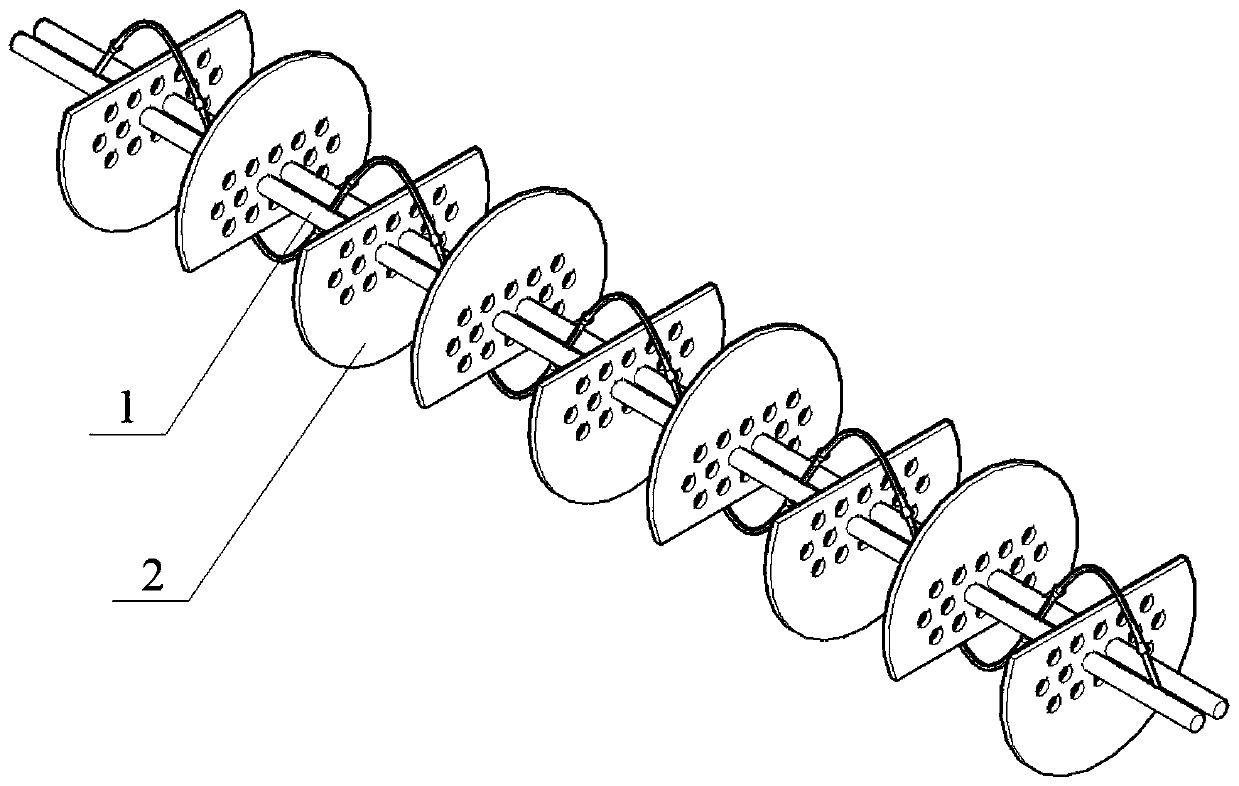

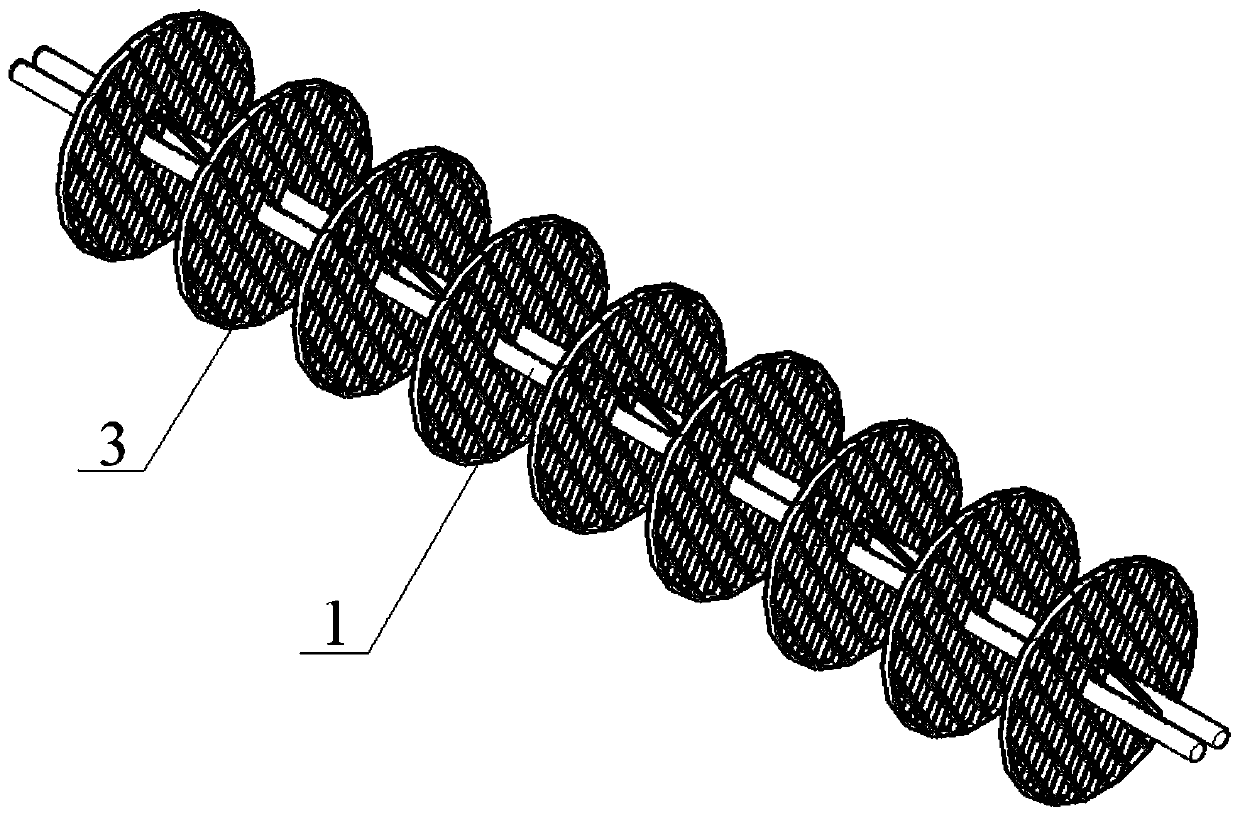

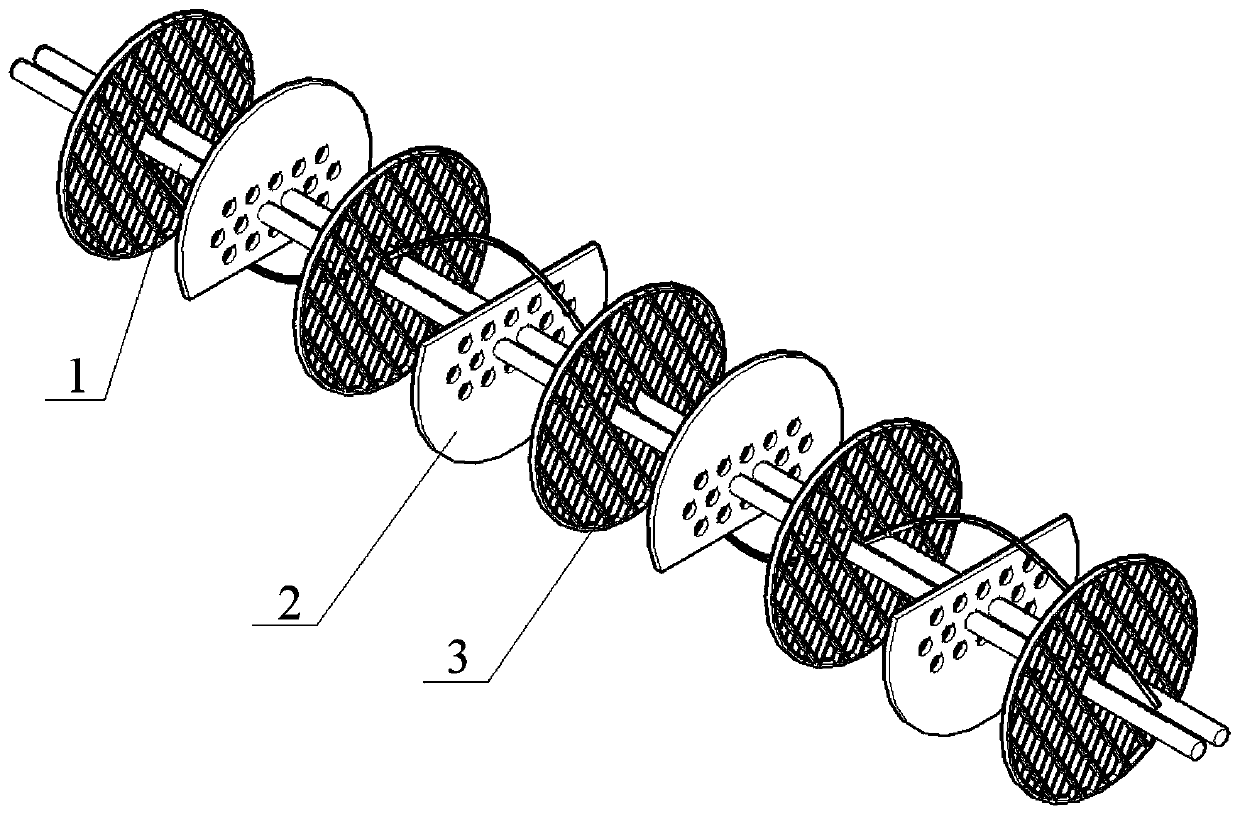

[0020] Such as image 3 As shown, the present invention provides a light-to-heat heat exchanger tube bundle support structure combined with baffles and vertical flow grids, which is characterized in that the tube bundle 1 is inserted into the regularly arranged baffles 2 and grids In the frame 3, two adjacent baffles 2 have a symmetrical structure, and a grid frame 3 is arranged between them.

[0021] The above structure is applied to the preheater in the photothermal steam generation system, the shell side medium is molten salt, and the tube side medium is feed water. The distance between the baffle plate 2 and the grid frame 3 is 500 mm, and the calculated flow resistance on the shell side is about 40 kPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com