H-shaped finned pipe formed by combining turbulence rods and delta vortex generators

A vortex generator, triangular technology, applied in the field of heat exchange and heating equipment, to achieve the effect of improving convective heat transfer coefficient, reducing pressure drop loss, and increasing disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

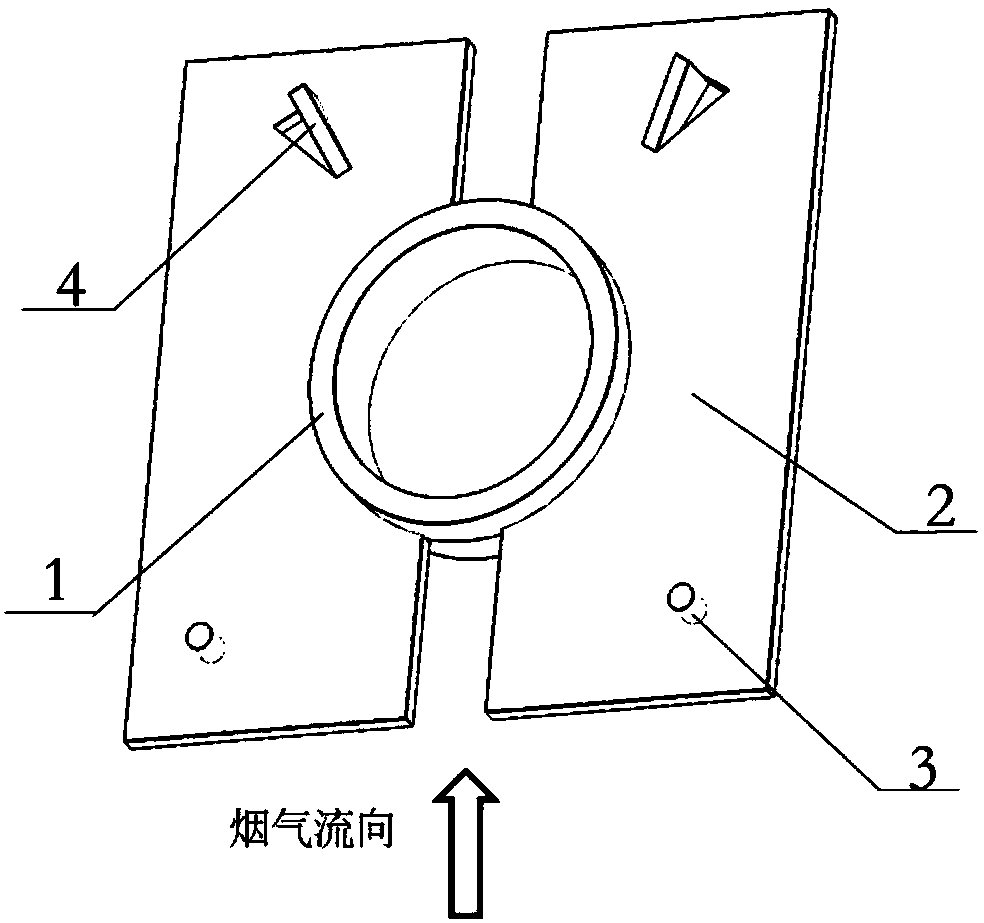

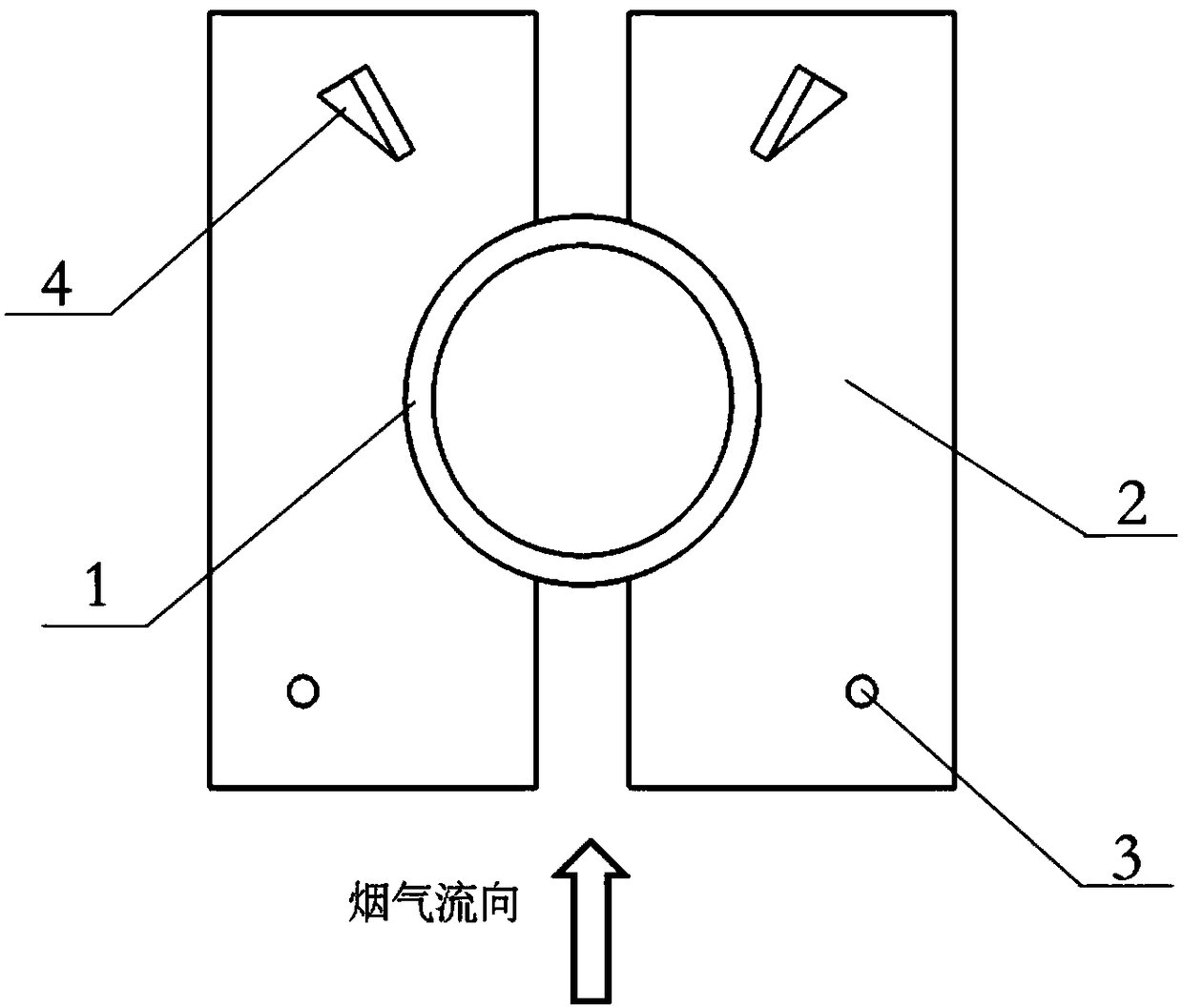

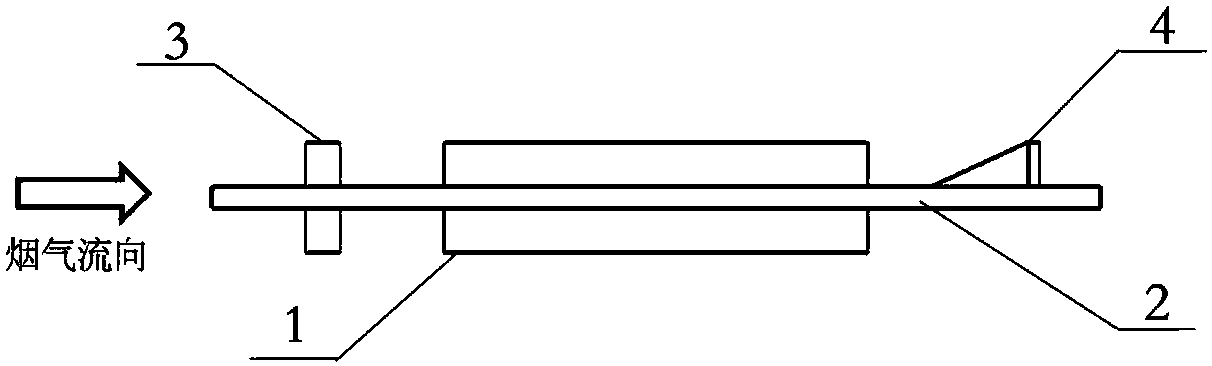

[0026] Such as figure 1 , figure 2 and image 3 As shown, an H-shaped finned tube combined with a spoiler bar and a triangular vortex generator includes a base tube 1 and several groups of H-shaped fin groups 2 set in parallel on the base tube 1, and the H-shaped fins The sheet group 2 is composed of two fins; each group of H-shaped fin group 2 is located on the two sides of the base pipe 1. Several pairs of spoiler rods 3 are symmetrically arranged on the windward side, and a pair of triangular vortex generators 4 are symmetrically arranged on the leeward side. , the windward side fins on both sides of the base pipe 1 are axially penetrated by the spoiler rod. The present invention cooperates with the base tube and the fin, and the fluency of the straight channel type flue gas channel formed by the base tube, the fin, the spoiler ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com