Array spherical hot runner plate heat exchanger

A technology of plate heat exchanger and hot runner plate, which is applied in heat exchange equipment, heat transfer modification, heat treatment furnace and other directions, can solve the problems of low cost, polluted raw materials, easy generation of aluminum ions, etc., and achieves light weight and moderate cost. , the effect of biosafety biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

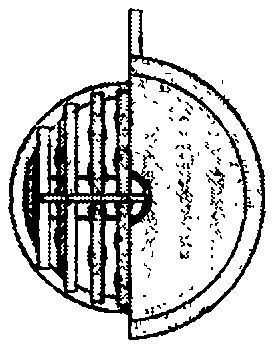

[0036] First, the hot runner welding of the two plates is completed simultaneously to increase the strength and thermal conductivity of the titanium-coated nano-diamond and the solid solution of the 6063 plate.

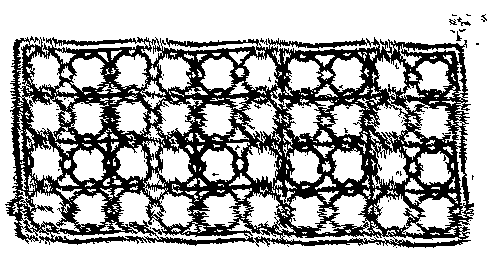

[0037] Hot forging 6063 plate mold to form microchannel array spherical plate surface.

[0038] The surface of the plate was pickled, and the surface was vacuum-sprayed with 30 μm thick titanium-plated nano-diamond.

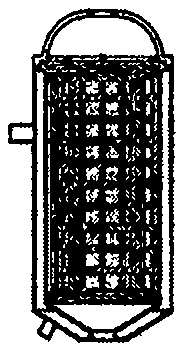

[0039] Merge and align the two boards, leaving a full channel.

[0040] Put them in the vacuum furnace one by one, and at the same time give it an appropriate temperature and diffusion pressure, and quench.

[0041] Slowly infiltrate nano-diamonds into the aluminum alloy to enhance its strength and thermal conductivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com