Movable gas shock-wave ash clearing gun

A gas shock wave, mobile technology, applied in combustion methods, removal of solid residues, combustion products treatment, etc., can solve the problems of high equipment operation failure rate, many failure points, limited number and other problems, and achieve equipment operation failure rate. The effect of low cost, simple equipment structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

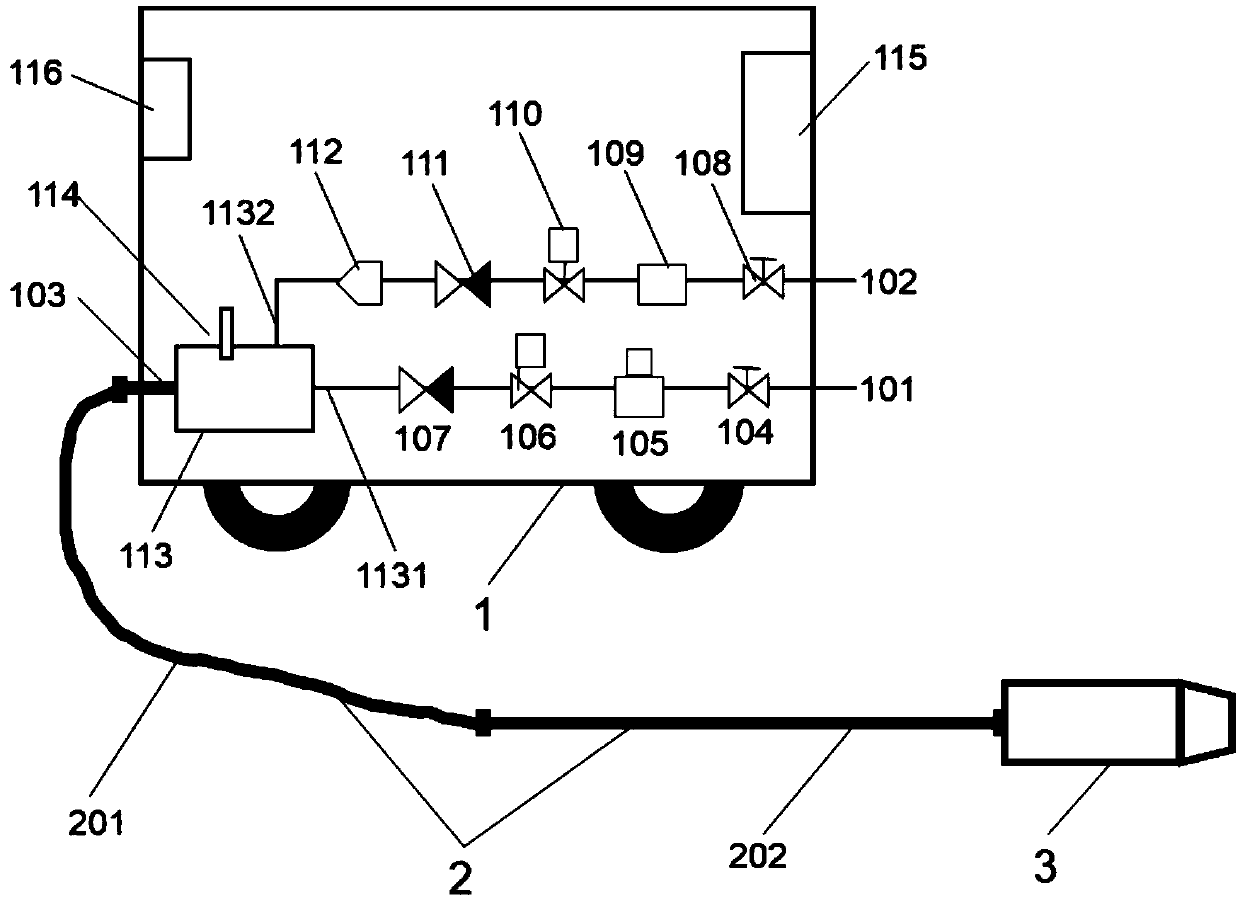

[0029] figure 1 It is a schematic structural diagram of a mobile gas shock wave cleaning gun in an embodiment of the present invention. Such as figure 1 As shown, the cleaning gun includes:

[0030] Ignition control box 1, described ignition control box 1 specifically comprises:

[0031] Electrical control device 115;

[0032] Further, the electrical control device 115 includes an air switch, a push button switch, a time relay, an igniter 116, an ignition wire, a control cable, and electrical components, wherein the igniter 116 is connected with the hybrid ignition through the ignition wire. The ignition head 114 of the device 113 is connected.

[0033] Further, four universal joint steering wheels are arranged at the bottom of the ignition control box 1 .

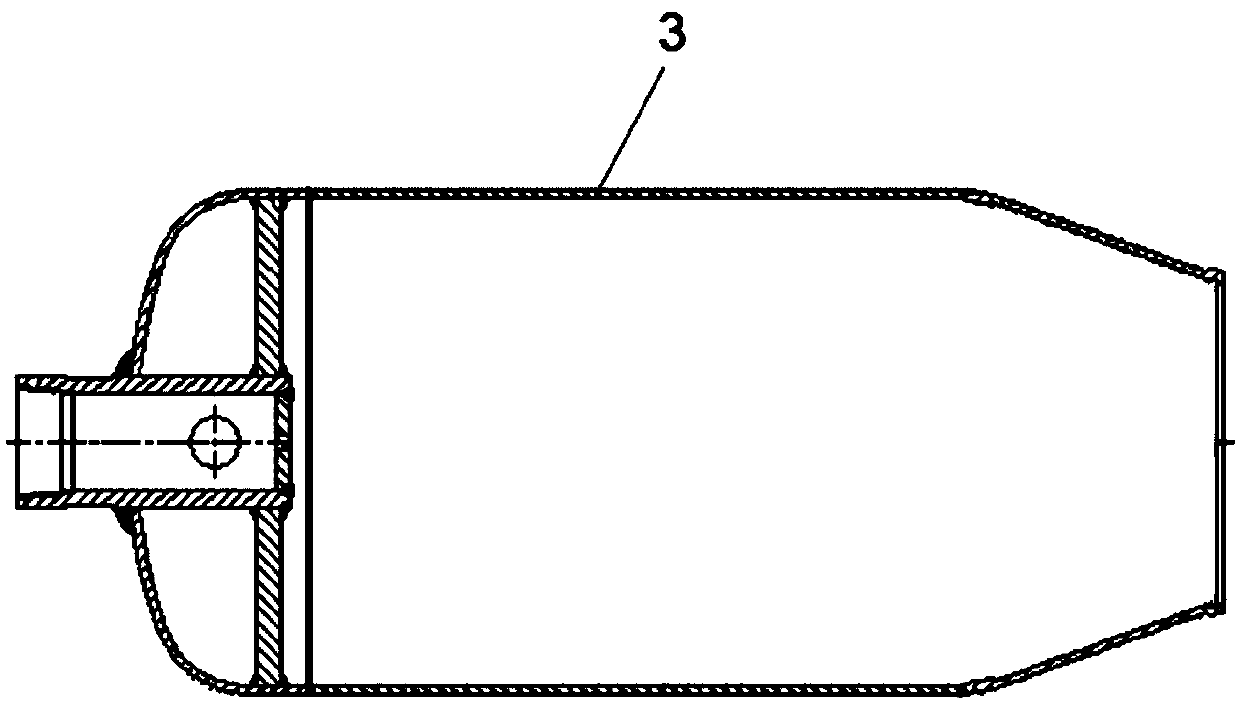

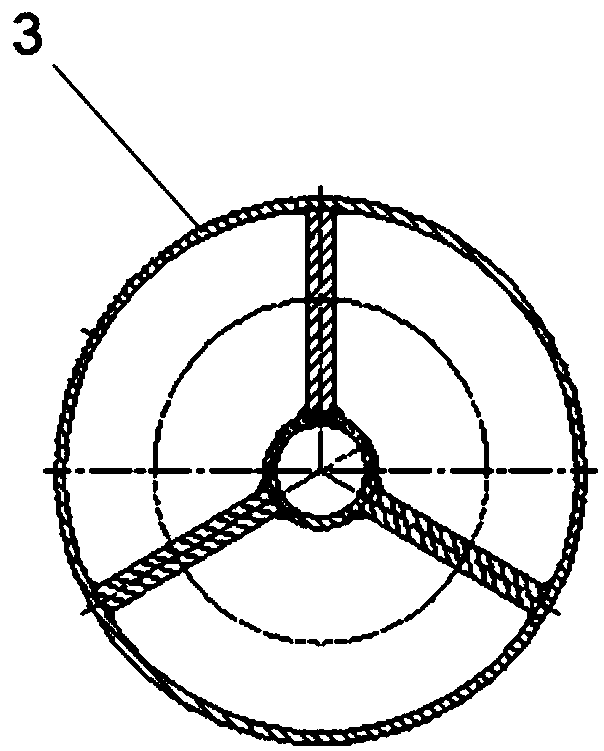

[0034]Specifically, the electrical control device 115 automatically delivers quantitative air and gas according to the set ash removal control program, and fills the gun barrel head 3 after being fully mixed in the mi...

Embodiment 2

[0054] The following is a detailed description of the use method of a mobile gas shock wave cleaning gun in the embodiment of the present invention, as follows:

[0055] When the heating surface of a certain part of the boiler needs to be cleaned, the movable mixed ignition control box 1 of the mobile gas shock wave cleaning gun is moved to the nearest platform of the heated surface of the part, and the mixed ignition control is turned on. The power supply of the box 1, and open the air manual valve 104 of the air pipeline device and the gas manual valve 108 of the gas pipeline device by a certain ratio. Then, according to the cleaning position and distance conditions, select the flexible connection pipe 201, the hard connection pipe 202 and a certain gun barrel head 3 to be connected by a quick connector.

[0056] The soot removal operator puts the above-mentioned gun barrel head 3 deep into the position to be cleaned in the furnace through the soot removal hole of the boiler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com