A skin-like oscillating hair heat dissipation coating

A technology of heat dissipation coating and fluff, which is applied in the field of skin-like oscillating fluff heat dissipation coating, can solve the problems of decreased heat dissipation effect and unsatisfactory effect, and achieves the effect of improving heat dissipation effect, improving heat dissipation effect and improving heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

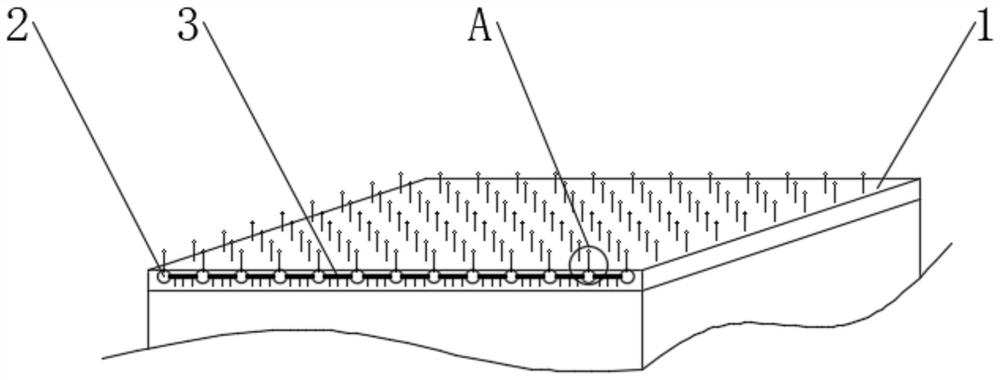

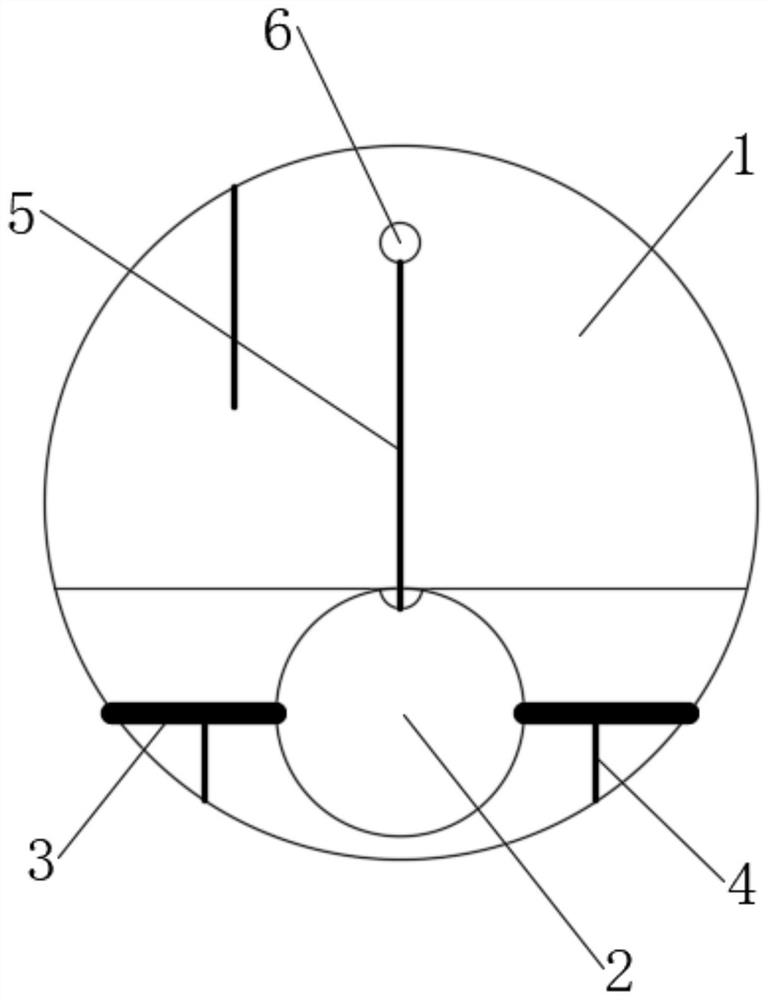

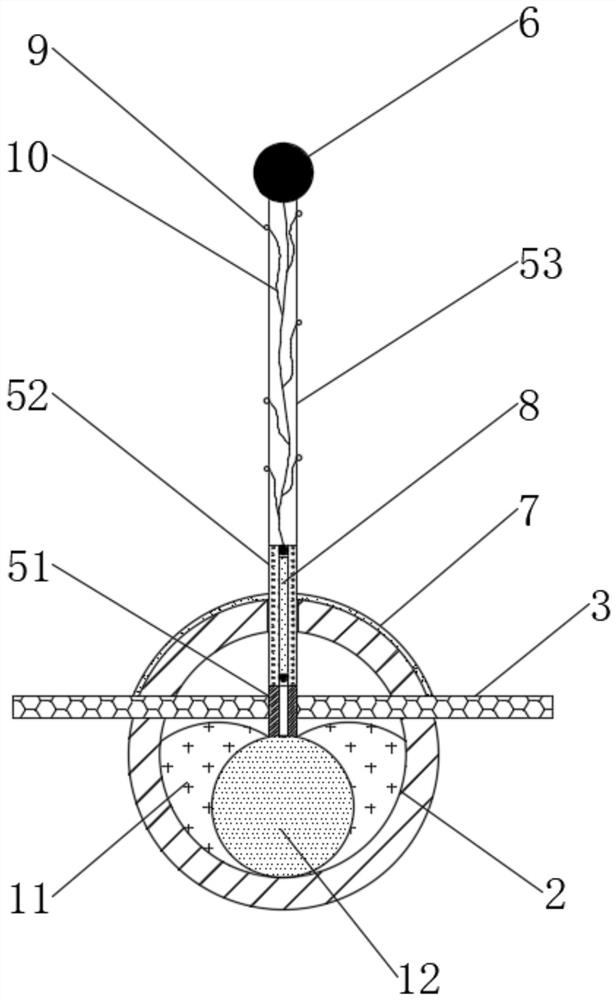

[0044] see Figure 1-2 , a skin-like swinging fluff heat dissipation coating, comprising a coating body 1, a plurality of uniformly distributed heat collecting balls 2 are inlaid and connected in the coating body 1, the heat collecting balls 2 are hollow structures, and the inside of the heat collecting balls 2 The air-supply base ball 12 is connected, and the thermal expansion wrap 11 is connected between the air-supply base ball 12 and the inner wall of the heat-collecting ball 2, and the upper end of the air-supply base ball 12 is connected with a double-effect heat dissipation composite rod 5, and the double-effect heat dissipation composite rod 5 runs through the heat collecting ball 2 and extends to the outside of the coating body 1, and the end of the double-effect heat dissipation composite rod 5 away from the heat collecting ball 2 is connected with a magnetic weight ball 6.

[0045] A heat conduction rod 3 is connected between adjacent heat collection balls 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com