Method for growing high-quality semiconductor single-walled carbon nanotube through in-situ weak hydrogen etching

A single-walled carbon nanotube, semiconducting technology, applied in the field of hydrogen in-situ weak etching to grow high-quality semiconducting single-walled carbon nanotubes, can solve the problem of damage to the intrinsic structure of single-walled carbon nanotubes, the introduction of impurities, and cumbersome steps and other issues, to achieve the effect of good industrial application prospects, low cost, and easy scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

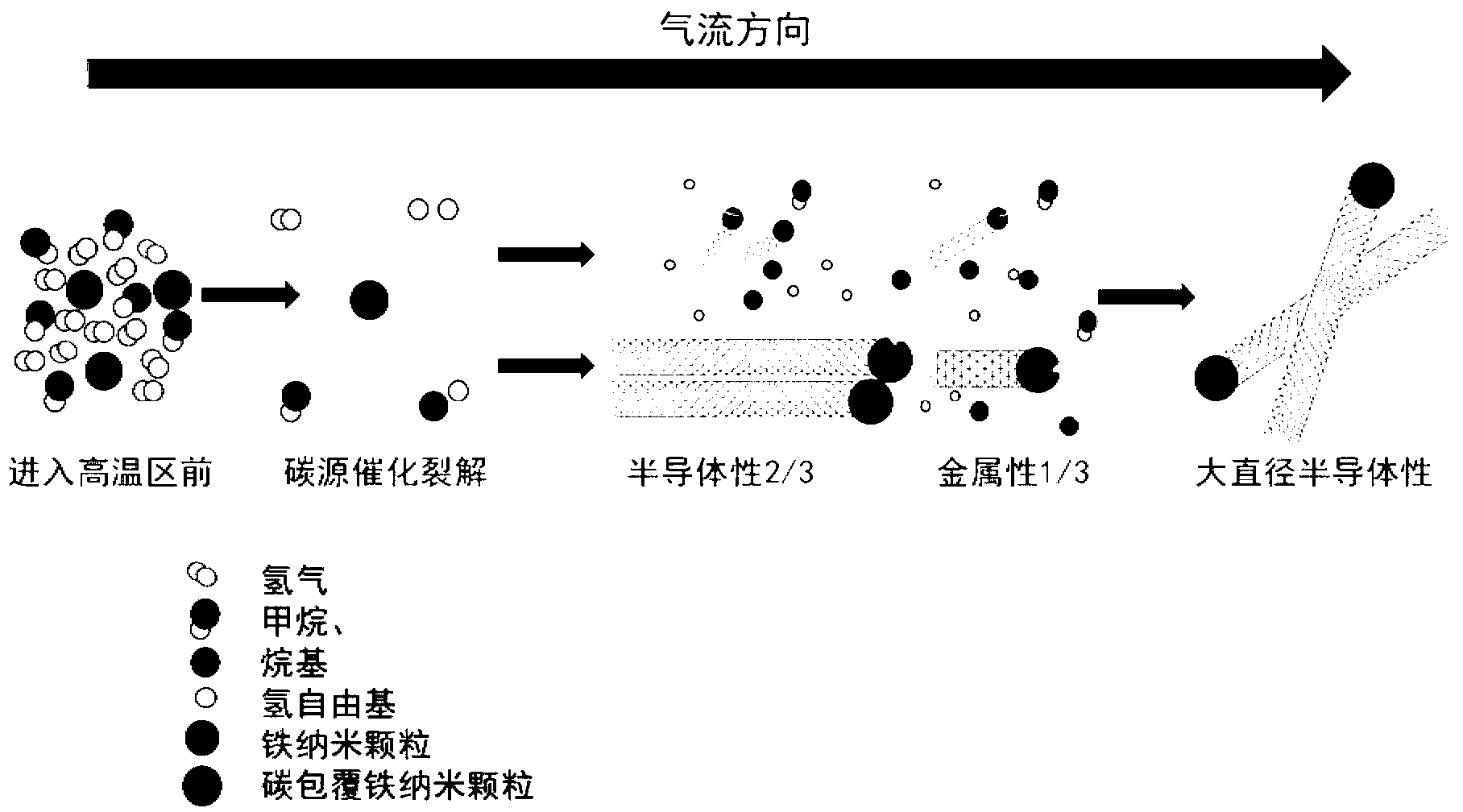

[0035] (1) figure 1 In order to prepare a schematic diagram of the principle of high-quality, semiconducting single-walled carbon nanotubes, the specific experimental steps are as follows: a piece of ferrocene containing sulfur powder (the weight ratio of sulfur powder to ferrocene is 1:200) is placed in the chemical vapor deposition In the low-temperature zone of the reaction furnace (50mm in diameter, 10cm in length of the constant temperature zone), the temperature rises to 1100°C at a rate of 22°C / min under a hydrogen atmosphere, and 30ml / min of methane is introduced, and the flow rate of hydrogen is adjusted to 2000ml / min. min, and at the same time push the ferrocene to a furnace with a temperature of 80° C. to grow single-walled carbon nanotubes for 30 minutes. After the chemical vapor deposition is finished, turn off the methane, and reduce the hydrogen flow rate to 400ml / min, allowing the reaction furnace to cool down to room temperature naturally.

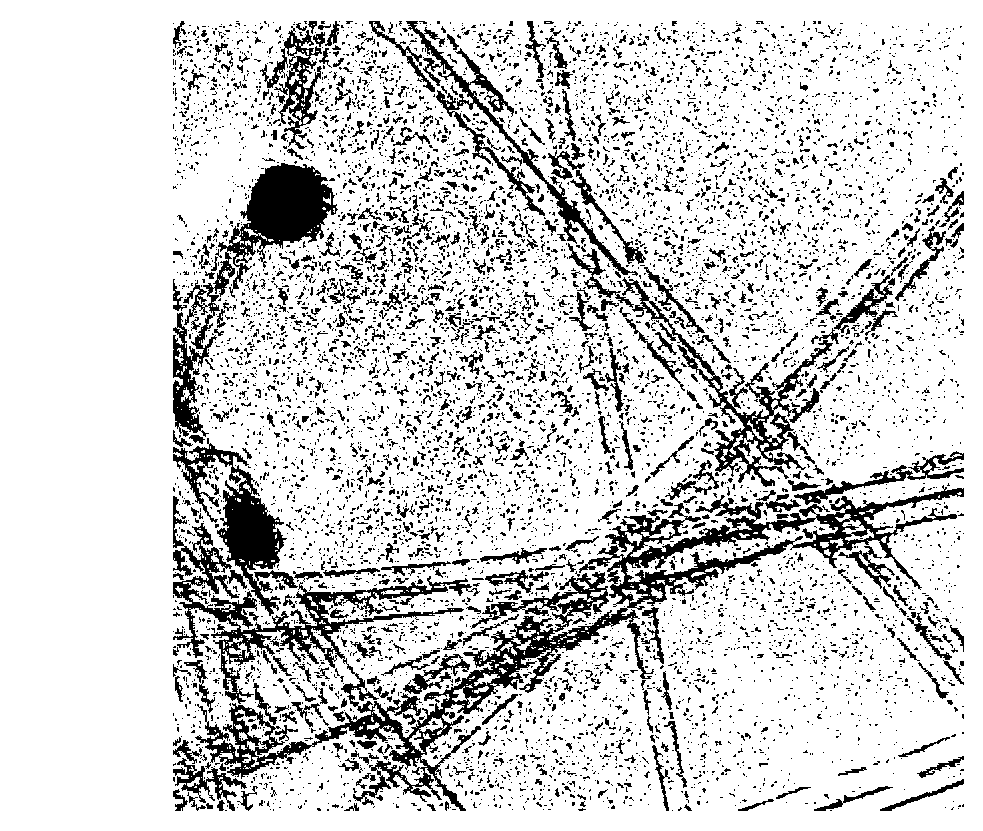

[0036] (2) The sa...

Embodiment 2

[0046] (1) Place a piece of nickelocene containing sulfur powder (the weight ratio of sulfur powder to nickelocene is 1:100) in the low temperature zone of the chemical vapor deposition reaction furnace (50mm in diameter, 10cm in length of the constant temperature zone). Under the hydrogen atmosphere, the temperature was raised to 1100°C at a rate of 22°C / min, and 20ml / min of methane was introduced, and the flow rate of hydrogen was adjusted to 2300ml / min. For the growth of walled carbon nanotubes, the growth time was 40 minutes. After the chemical vapor deposition is over, turn off the methane, and reduce the hydrogen flow rate to 400ml / min again, and allow the reaction furnace to cool down to room temperature by natural cooling.

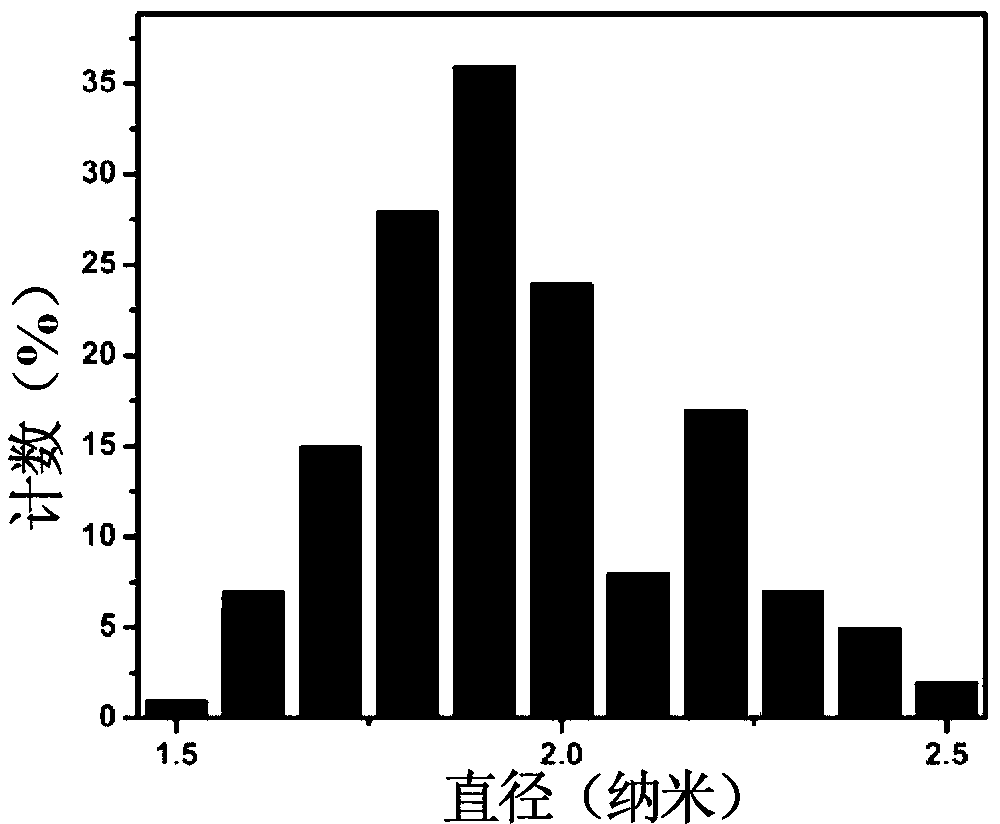

[0047] (2) The samples obtained in step (1) were characterized by transmission electron microscope, Raman spectrum and absorption spectrum respectively. The diameters of 146 single-walled carbon nanotubes were measured and counted under a transmis...

Embodiment 3

[0050](1) Place a piece of cobaltocene containing sulfur powder (the weight ratio of sulfur powder to cobaltocene is 1:150) in the low temperature zone of a chemical vapor deposition reaction furnace (50mm in diameter, 10cm in length of the constant temperature zone), in the Under a hydrogen atmosphere, the temperature was raised to 1050°C at a rate of 22°C / min, 25ml / min of ethylene was introduced, and the hydrogen flow rate was adjusted to 2500ml / min. For the growth of walled carbon nanotubes, the growth time was 50 minutes. After the chemical vapor deposition is finished, turn off ethylene, reduce the hydrogen flow rate to 400ml / min, and allow the reaction furnace to cool down to room temperature naturally.

[0051] (2) The samples obtained in step (1) were characterized by transmission electron microscope, Raman spectrum and absorption spectrum respectively. The diameters of 132 single-walled carbon nanotubes were measured and counted under the transmission electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com