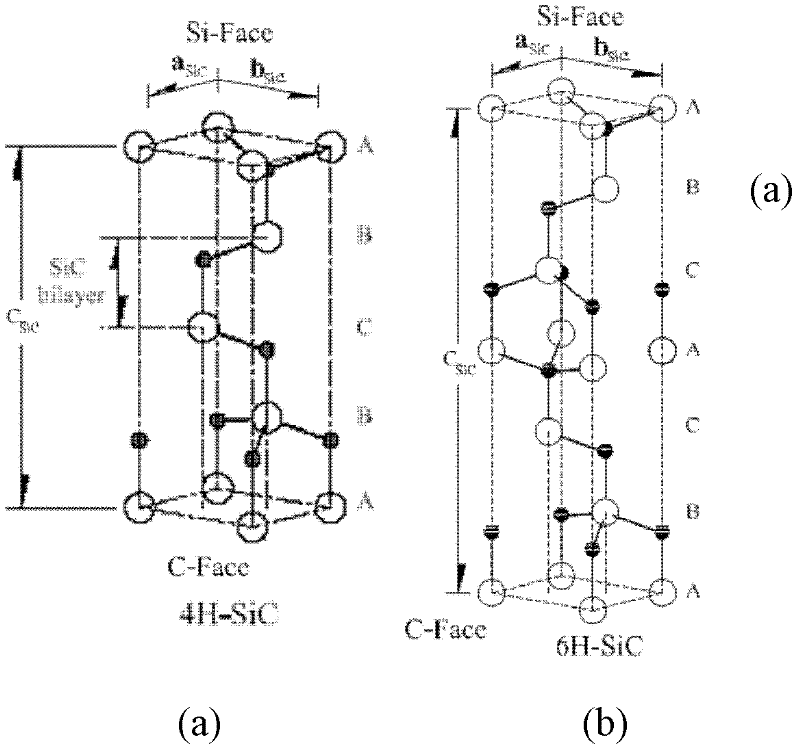

Method for epitaxial growth of wafer-level graphene on 4H/6H-SiC (0001) surface

An epitaxial growth, wafer-level technology, applied in the field of microelectronics, can solve the problems of low uniformity and small graphene area, and achieve the effect of improving the area and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

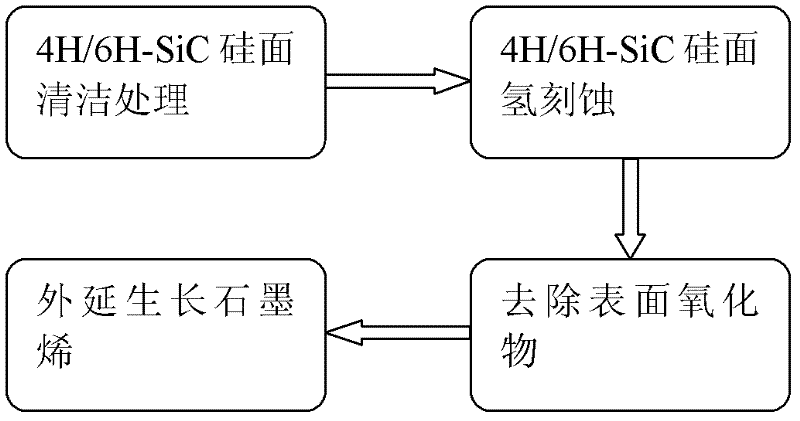

[0020] Embodiment 1, the steps of the present invention to epitaxially grow Graphene on the 4H-SiC(0001) silicon surface are as follows:

[0021] Step 1, remove sample surface pollutants.

[0022] Clean the silicon surface of 4H-SiC(0001). Place the SiC in deionized water for ultrasonic cleaning for 15 minutes, take it out, and rinse repeatedly; soak the SiC in a solution of ammonia: hydrogen peroxide: deionized water = 1:2:5, boil, soak for 15 minutes, and wash repeatedly with deionized water; SiC was immersed in hydrochloric acid: hydrogen peroxide: deionized water = 1:2:8 solution and boiled for 15min, then washed repeatedly with deionized water; put SiC in 5% HF solution for 1min, and rinsed with deionized water; place SiC in deionized water Clean in the ultrasonic wave of ion water for 15min, rinse repeatedly, take out and dry.

[0023] Step 2, performing hydrogen etching on the 4H-SiC(0001) silicon surface.

[0024] Place the cleaned 4H-SiC silicon surface in the CVD ...

Embodiment 2

[0029] Embodiment 2, the step of the present invention epitaxially growing graphene on the 6H-SiC silicon surface is as follows:

[0030] Step 1, cleaning the surface of the 6H-SiC(0001) silicon surface to remove pollutants on the sample surface.

[0031] 1a) Place the SiC in deionized water for ultrasonic cleaning for 15 minutes, take it out, and rinse repeatedly;

[0032] 1b) Soak the SiC in a solution of ammonia water: hydrogen peroxide: deionized water = 1:2:5, boil, soak for 15 minutes, and wash repeatedly with deionized water;

[0033] 1c) Immerse the SiC in a solution of hydrochloric acid: hydrogen peroxide: ionized water = 1:2:8 and boil for 15 minutes, then wash it repeatedly with deionized water;

[0034] 1d) Put SiC in 5% HF solution for 1 min, and rinse with deionized water;

[0035] 1e) Place the SiC in deionized water for ultrasonic cleaning for 15 minutes, rinse repeatedly, take it out and dry it.

[0036] Step 2, performing hydrogen etching on the 6H-SiC (00...

Embodiment 3

[0042] Embodiment 3, the steps of the present invention to epitaxially grow Graphene on the 6H-SiC silicon surface are as follows:

[0043] Step A, cleaning the surface of the 6H-SiC(0001) silicon surface to remove pollutants on the surface of the sample.

[0044] Place the SiC in the ultrasonic wave of deionized water and clean it for 15 minutes, take it out, and rinse it repeatedly;

[0045] Soak SiC in a solution of ammonia: hydrogen peroxide: deionized water = 1:2:5, boil, soak for 15 minutes, and wash repeatedly with deionized water;

[0046] Immerse SiC in a solution of hydrochloric acid: hydrogen peroxide: deionized water = 1:2:8, boil for 15 minutes, and wash with deionized water repeatedly;

[0047] Put SiC in 5% HF solution for 1min, rinse with deionized water;

[0048] Place the SiC in deionized water for ultrasonic cleaning for 15 minutes, rinse repeatedly, take it out and dry it.

[0049] Step B, performing hydrogen etching on the 6H-SiC (0001) silicon surface....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com