Method for preparing graphene nanoribbon

A technology of graphene nanoribbons and epitaxy, applied in the direction of graphene, nanocarbon, chemical instruments and methods, etc., can solve the problems of unfavorable device technology of graphene nanoribbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

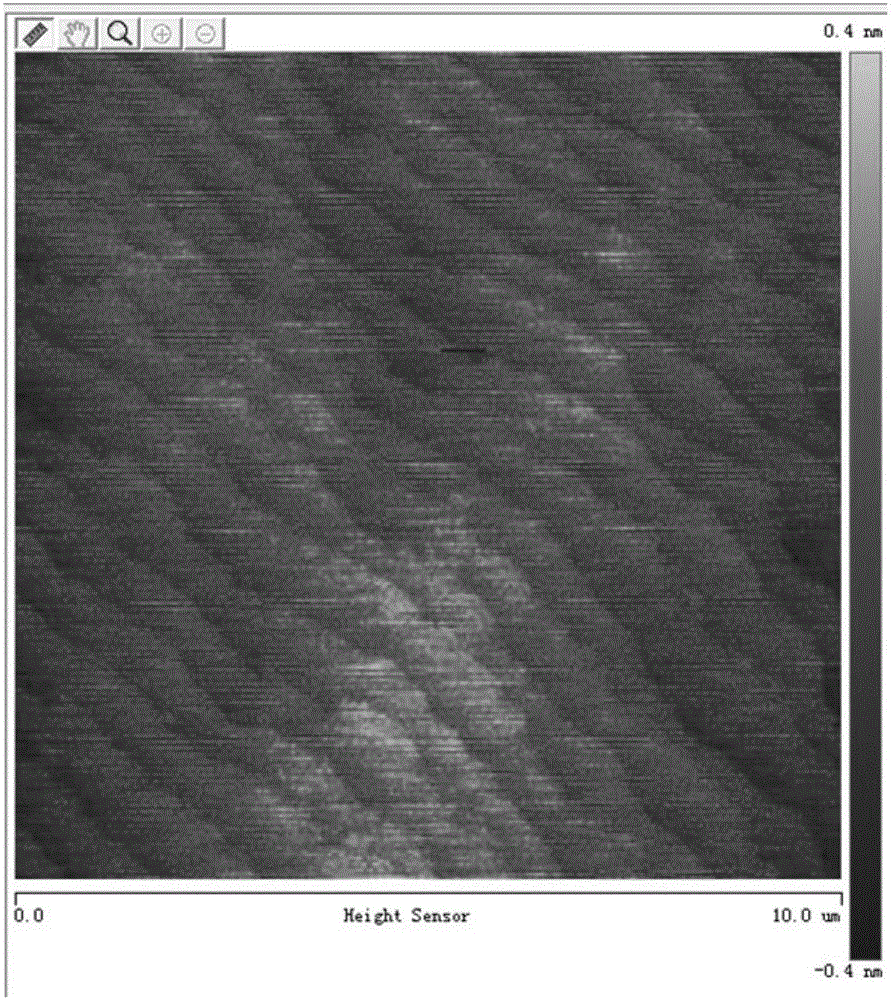

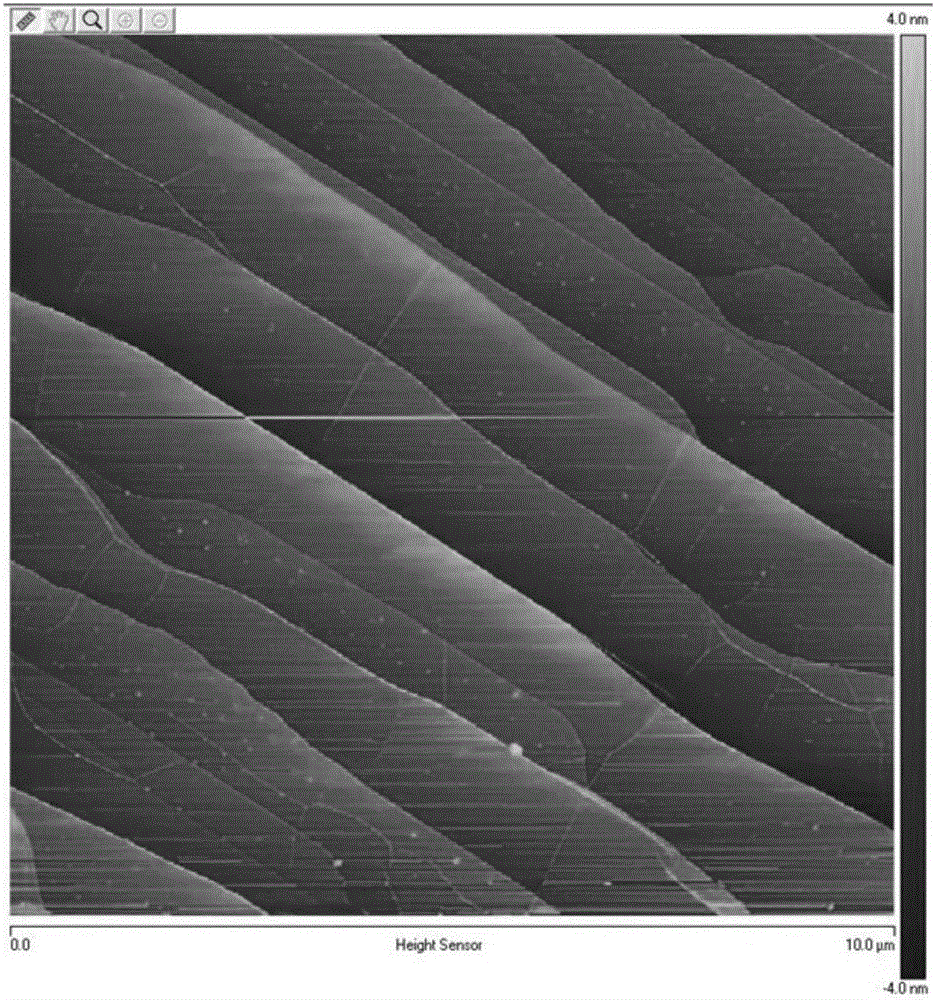

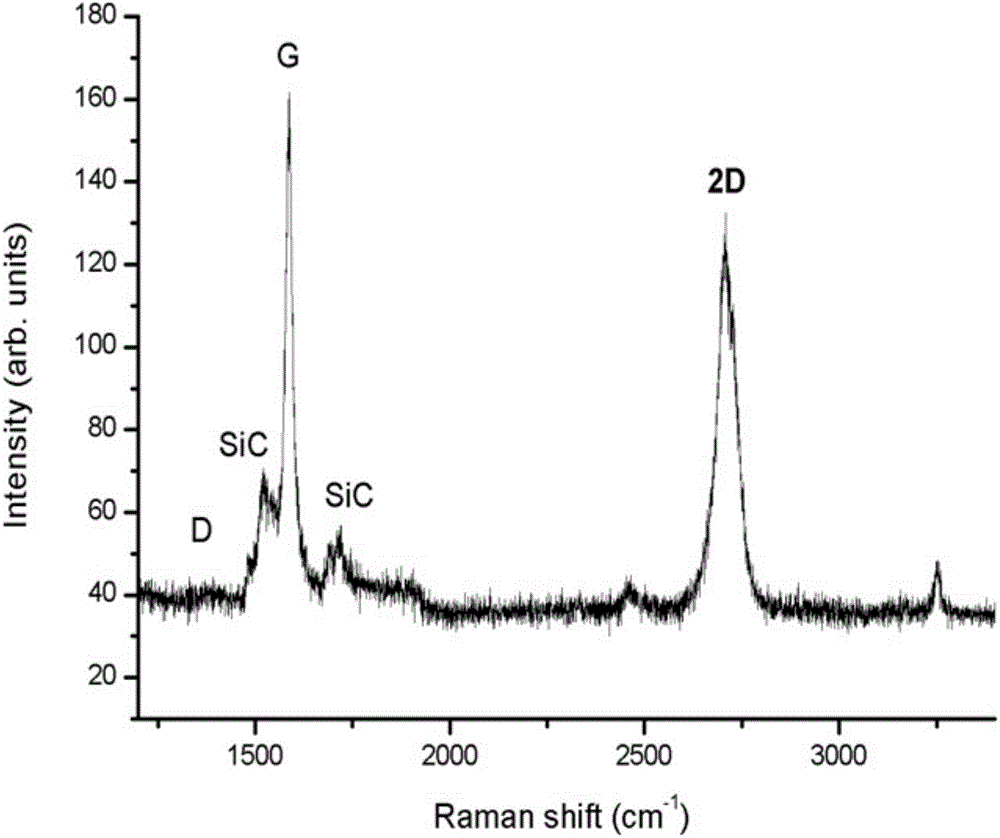

[0038] A graphene nanoribbon with a width of 200nm is prepared with a silicon carbide substrate, and the specific method is as follows:

[0039] First, polish the silicon carbide substrate; then perform chemical cleaning: the first step, immerse SiC in a mixture of ammonia: hydrogen peroxide: deionized water at a ratio of 1:2:5, boil for 10 minutes, and clean with deionized water for 3 times; the second step, immerse the substrate in hydrochloric acid: hydrogen peroxide: deionized water = 1:2:8, boil for 5 minutes, and wash with deionized water for 3 times; the third step, put it in 3% HF solution for 1 minute, and wash it with deionized water Rinse with water.

[0040] Then carry out hydrogen etching: hydrogen etching off angle is 2°, temperature is 1500°C, H 2 The flow rate is 80L / min, the pressure is 120mbar, and the time is 5min.

[0041] Then remove the oxide: place the substrate in a high-temperature furnace, the temperature in the high-temperature furnace is 1100 ° C,...

Embodiment 2

[0044] A graphene nanoribbon with a width of 80 nm is prepared with a silicon carbide substrate, and the specific method is as follows:

[0045] First, polish the silicon carbide substrate; then perform chemical cleaning: the first step, immerse the SiC in a mixture of ammonia water: hydrogen peroxide: deionized water at a ratio of 2:3:5, boil for 5 minutes, and clean with deionized water for 3 times; the second step, immerse the substrate in hydrochloric acid: hydrogen peroxide: deionized water = 1:3:8, boil for 10 minutes, and wash with deionized water for 3 times; the third step, put it in 10% HF solution for 5 minutes, use deionized Rinse with water.

[0046] Then carry out hydrogen etching: the off angle of hydrogen etching is 4°, the temperature is 1300°C, H 2 The flow rate is 50L / min, the pressure is 100mbar, and the time is 5min.

[0047] Then remove the oxide: place the substrate in a high-temperature furnace, the temperature in the high-temperature furnace is 900 °...

Embodiment 3

[0050] The graphene nanobelts with a width of 30nm are prepared on a silicon carbide substrate, and the specific method is as follows:

[0051] First, polish the silicon carbide substrate; then perform chemical cleaning: the first step, immerse the SiC in a mixture of ammonia: hydrogen peroxide: deionized water at a ratio of 2:4:5, boil for 10 minutes, and clean with deionized water for 4 times; the second step, immerse the substrate in hydrochloric acid: hydrogen peroxide: deionized water = 1:5:8, boil for 5 minutes, and wash with deionized water for 3 times; the third step, put it in 15% HF solution for 10 minutes, use deionized water Rinse with water.

[0052] Then carry out hydrogen etching: hydrogen etching off angle is 8°, temperature is 1800°C, H 2 The flow rate is 100L / min, the pressure is 120mbar, and the time is 30min.

[0053] Then remove the oxide: put the substrate in a high-temperature furnace, the temperature in the high-temperature furnace is 1300 ° C, H 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com