Preparation method of tin dioxide/titanium dioxide spherical particle and graphene nanoribbon composite material

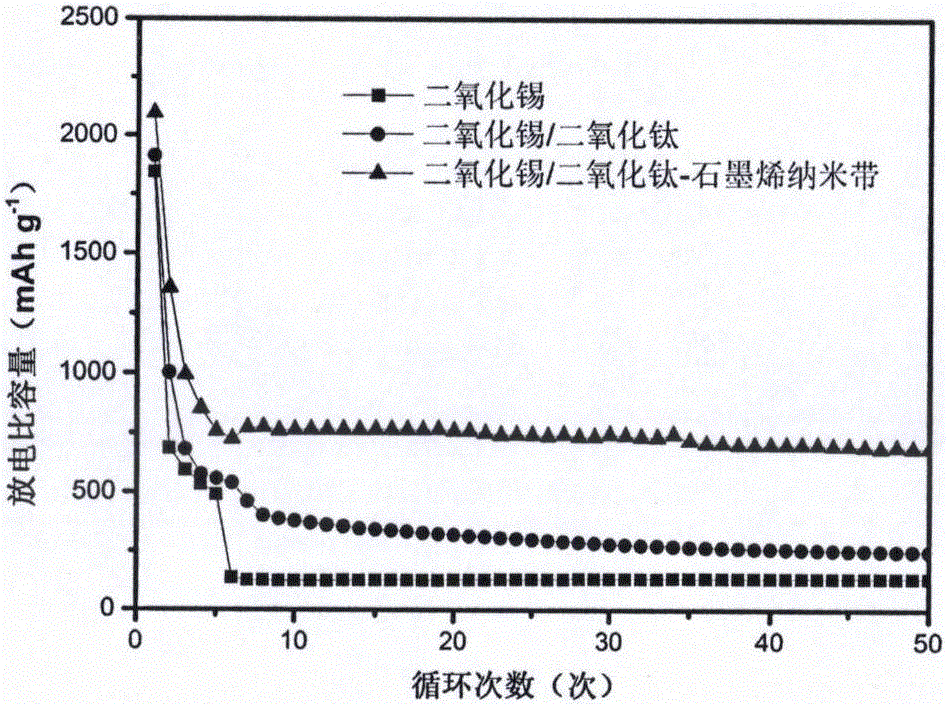

A graphene nanoribbon and tin dioxide technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of tin dioxide volume expansion that has not been fundamentally solved, poor conductivity of titanium dioxide, strong corrosion and volatility, etc. , to achieve the effect of large-scale production, good conductivity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The concrete steps of a kind of preparation method of tin dioxide / titanium dioxide spherical particle and graphene nanoribbon compound are as follows:

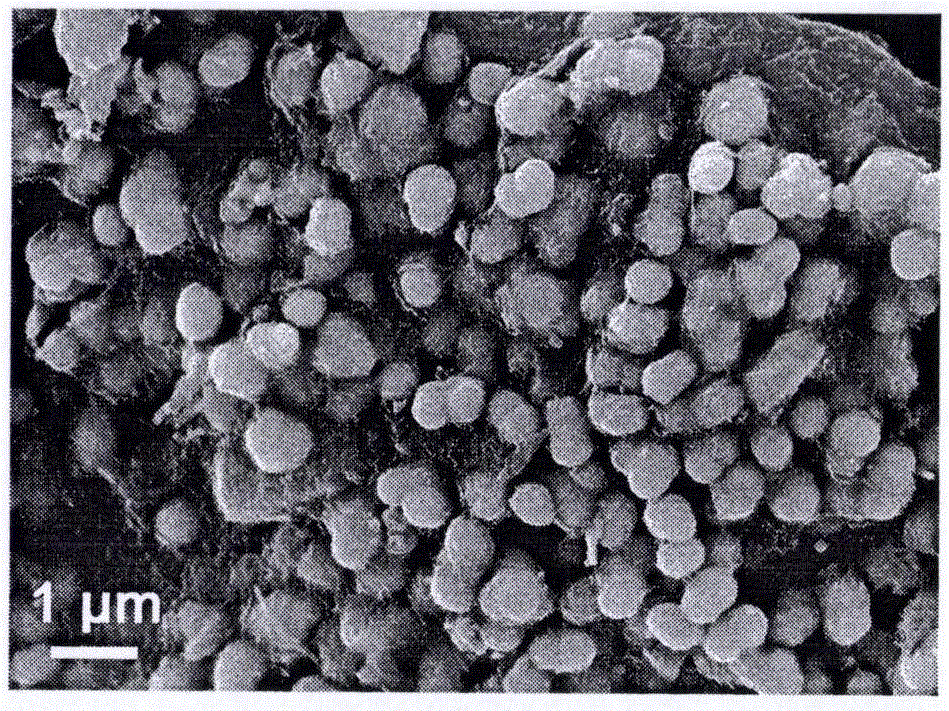

[0025] 1) Preparation of tin dioxide / titanium dioxide spherical particles

[0026] 1.1) according to the quality (g) of potassium stannate: the quality (g) of urea: the volume (mL) of dehydrated alcohol: the ratio of the volume (mL) of deionized water is 1: 2: 60: 70 ratio, will Potassium stannate and urea were added to absolute ethanol and deionized water, and ultrasonically oscillated for 1 hour to obtain the mixed solution A;

[0027] 1.2) Put the mixed liquid A in a reaction kettle, carry out a hydrothermal reaction at a temperature of 150°C for 12 hours, let the collected liquid stand for 1 hour, and then dry the lower layer of solid matter at 60°C for 12 hours, Just make tin dioxide hollow sphere powder;

[0028] 1.3) According to the ratio of the mass (g) of tin dioxide: the volume (mL) of absolute ethanol is 1...

Embodiment 2

[0036] The concrete steps of a kind of preparation method of tin dioxide / titanium dioxide spherical particle and graphene nanoribbon compound are as follows:

[0037] 1) Preparation of tin dioxide / titanium dioxide spherical particles

[0038] 1.1) according to the quality (g) of potassium stannate: the quality (g) of urea: the volume (mL) of dehydrated alcohol: the ratio of the volume (mL) of deionized water is 1: 1: 70: 60 ratio, will Potassium stannate and urea were added to absolute ethanol and deionized water, and ultrasonically oscillated for 2 hours to obtain a mixed solution A;

[0039] 1.2) Put the mixed liquid A in a reaction kettle, carry out a hydrothermal reaction at a temperature of 160°C for 18 hours, let the collected liquid stand for 2 hours, and then dry the solid substance in the lower layer at 50°C for 10 hours, Just make tin dioxide hollow sphere powder;

[0040]1.3) According to the ratio of the mass (g) of tin dioxide: the volume (mL) of absolute ethano...

Embodiment 3

[0048] 1) Preparation of tin dioxide / titanium dioxide spherical particles

[0049] 1.1) according to the quality (g) of potassium stannate: the quality (g) of urea: the volume (mL) of dehydrated alcohol: the ratio of the volume (mL) of deionized water is 1: 3: 100: 100 ratio, will Potassium stannate and urea were added to absolute ethanol and deionized water, and ultrasonically oscillated for 3 hours to obtain a mixed solution A;

[0050] 1.2) Put the mixed solution A in a reaction kettle, carry out a hydrothermal reaction at a temperature of 180°C for 30 hours, let the collected liquid stand for 3 hours, and dry the lower layer of solid matter at 110°C for 23 hours, Just make tin dioxide hollow sphere powder;

[0051] 1.3) According to the ratio of the mass (g) of tin dioxide: the volume (mL) of absolute ethanol is 1: 1000, mix to obtain the mixed solution B, according to the volume (ml) of ammonia water: the volume of tetrabutyl titanate (ml): The ratio of volume (mL) of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com