Method for preparing graphene and graphene device by epitaxy of pretreated SiC substrate

A graphene and pretreatment technology, applied in the field of microelectronic materials, can solve the problems of reduced growth rate, random microscopic nucleation sites, etc., and achieve the effects of reducing nucleation density, high-quality surface morphology, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing graphene and graphene devices by pretreatment of SiC substrate epitaxy, comprising steps as follows:

[0053] The SiC wafer obtained by cutting, grinding, mechanical polishing and chemical mechanical polishing of the SiC block has regular atomic-level steps on the surface, and is then cleaned by RCA standard cleaning method. Introduce hydrogen gas into the furnace cavity for hydrogen etching. The hydrogen etching temperature is 1600°C, the hydrogen flow rate is 50 sccm, the argon gas flow rate is 800 sccm, the pressure is 900 mbar, and the hydrogen etching time is 30 minutes; after that, vacuuming is performed, and the vacuum degree is 5×10 -5 Pa; completely pump out the gas in the furnace chamber;

[0054] (2) oxidation

[0055] Perform pre-oxidation treatment on the wafer after hydrogen etching, the oxygen flow rate is 20 sccm, the argon gas flow rate is 800 sccm, the chamber pressure is 800 mbar, the temperature ...

Embodiment 2

[0061] A method for preparing graphene and graphene devices by pretreatment of SiC substrate epitaxy, comprising steps as follows:

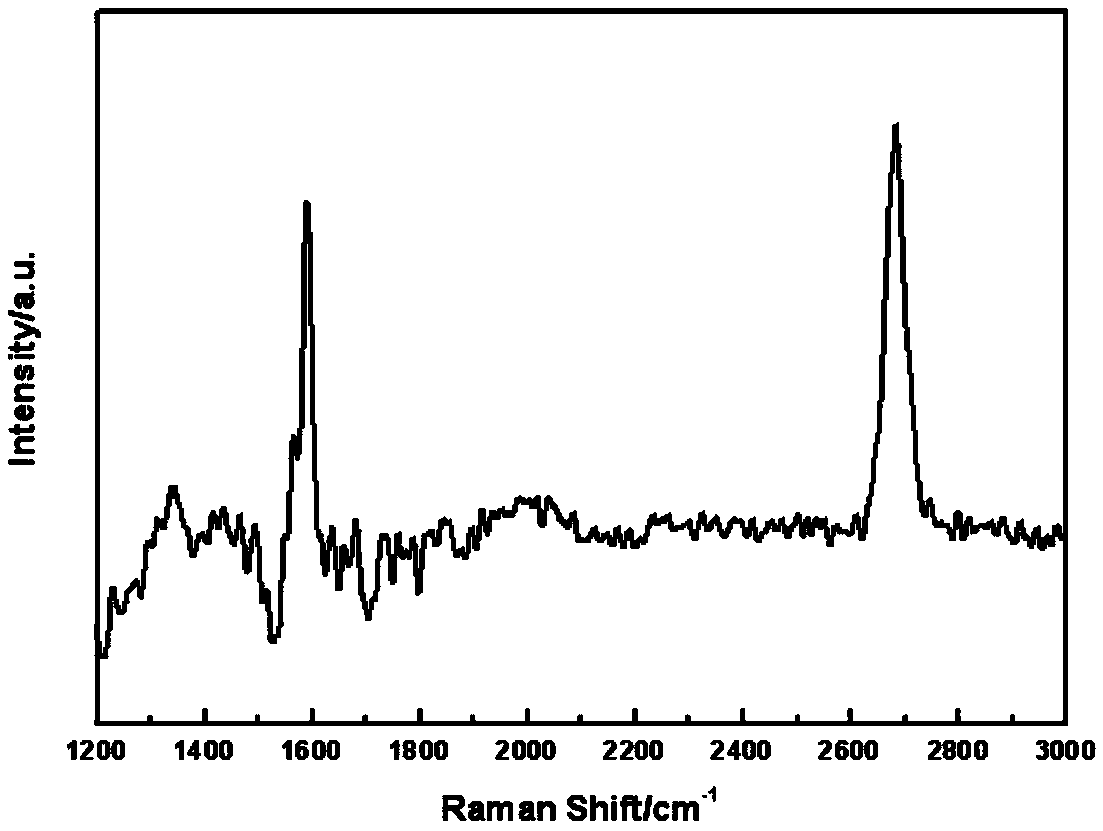

[0062] As described in Example 1, the difference is that the growth surface used is the (000-1) carbon surface of SiC, the SiC wafer is placed in the furnace chamber, and then the oxidation treatment process is carried out, the oxidation temperature is 500°C, and the oxygen flow rate 50sccm, oxidation treatment time 60min; graphene growth temperature 1450°C, growth time 120min.

[0063] The epitaxially grown graphene wafer on the SiC substrate is subjected to metal evaporation, photolithography and integration procedures, and finally the corresponding MOSFET device is prepared, and the carrier mobility of the obtained SiC epitaxial graphene is ~10000cm 2 ·V -1 ·s -1 .

Embodiment 3

[0065] A method for preparing graphene and graphene devices by pretreatment of SiC substrate epitaxy, comprising steps as follows:

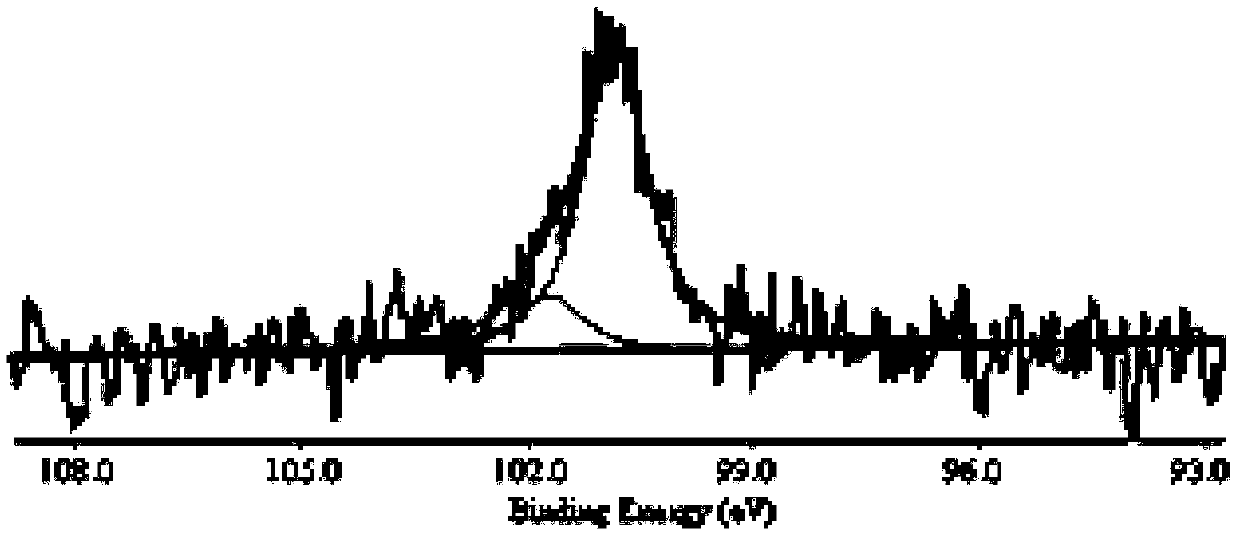

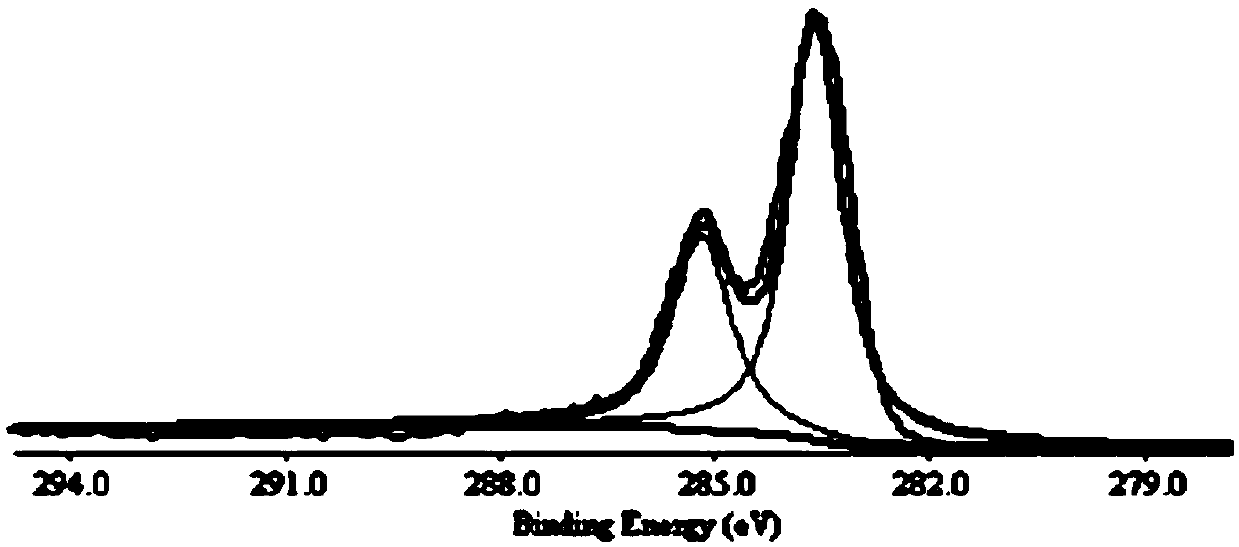

[0066] As described in Example 1, the differences are: oxidation temperature 1300°C, oxygen flow 5sccm, oxidation treatment time 120min; graphene growth temperature 1700°C, growth time 30min; temperature rise rate to reach the target growth temperature 5°C / min, During the cooling process, the cooling rate was 5°C / min. The number of layers of the grown graphene is uniform, and its morphology is as follows: Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com