CVD monocrystalline diamond growth pretreatment method

A single crystal diamond, pretreatment technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of surface contamination of the seed crystal, influence of the quality and purity of single crystal diamond, etc., to improve the quality and purity, improve The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

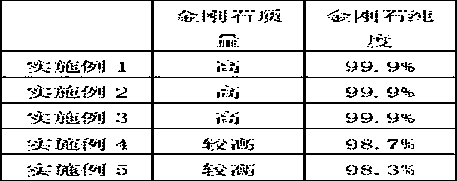

Examples

Embodiment 1

[0027] Select an ultra-thin single-crystal diamond with appropriate size, no obvious defects, and good quality as the substrate, put the diamond substrate into a cleaning container filled with 45°C acetone cleaning solution, and put the container into an ultrasonic cleaning tank, adjust The temperature in the ultrasonic cleaning tank is 45°C, and the ultrasonic cleaning is carried out for 30 minutes. The diamond substrate after ultrasonic cleaning is taken out and placed in a drying oven for drying treatment at a temperature of 65°C; 100ml of concentrated hydrochloric acid is measured, and Measure 900ml of distilled water, slowly pour 100ml of concentrated hydrochloric acid into 900ml of distilled water in a fume hood, and keep stirring to mix evenly. Soak in dilute hydrochloric acid solution for 45s for chemical cleaning. After cleaning, take out the diamond substrate and put it in a drying oven for drying at a temperature of 120°C;

[0028] Adopt the diamond substrate after ...

Embodiment 2

[0030] Select an ultra-thin single-crystal diamond with appropriate size, no obvious defects, and good quality as the substrate, put the diamond substrate into a cleaning container filled with 45°C acetone cleaning solution, and put the container into an ultrasonic cleaning tank, adjust The temperature in the ultrasonic cleaning tank is 45°C, and the ultrasonic cleaning is carried out for 30 minutes. The diamond substrate after ultrasonic cleaning is taken out and placed in a drying oven for drying treatment at a temperature of 65°C; 100ml of concentrated hydrochloric acid is measured, and Measure 900ml of distilled water, slowly pour 100ml of concentrated hydrochloric acid into 900ml of distilled water in a fume hood, and keep stirring to mix evenly. Soak in dilute hydrochloric acid solution for 45s for chemical cleaning. After cleaning, take out the diamond substrate and put it in a drying oven for drying at a temperature of 120°C;

[0031] Adopt the diamond substrate after ...

Embodiment 3

[0033] Select an ultra-thin single-crystal diamond with appropriate size, no obvious defects, and good quality as the substrate, put the diamond substrate into a cleaning container filled with 45°C acetone cleaning solution, and put the container into an ultrasonic cleaning tank, adjust The temperature in the ultrasonic cleaning tank is 45°C, and the ultrasonic cleaning is carried out for 30 minutes. The diamond substrate after ultrasonic cleaning is taken out and placed in a drying oven for drying treatment at a temperature of 65°C; 100ml of concentrated hydrochloric acid is measured, and Measure 900ml of distilled water, slowly pour 100ml of concentrated hydrochloric acid into 900ml of distilled water in a fume hood, and keep stirring to mix evenly. Soak in dilute hydrochloric acid solution for 45s for chemical cleaning. After cleaning, take out the diamond substrate and put it in a drying oven for drying at a temperature of 120°C;

[0034]Adopt the diamond substrate after c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com