Pyrolytic graphite composite coating and applications thereof

A technology of pyrolytic graphite and composite coating, applied in the direction of coating, metal material coating process, phosphorus compound, etc., can solve the problems of low van der Waals bonding force between layers, affecting the appearance of products, and large distance between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

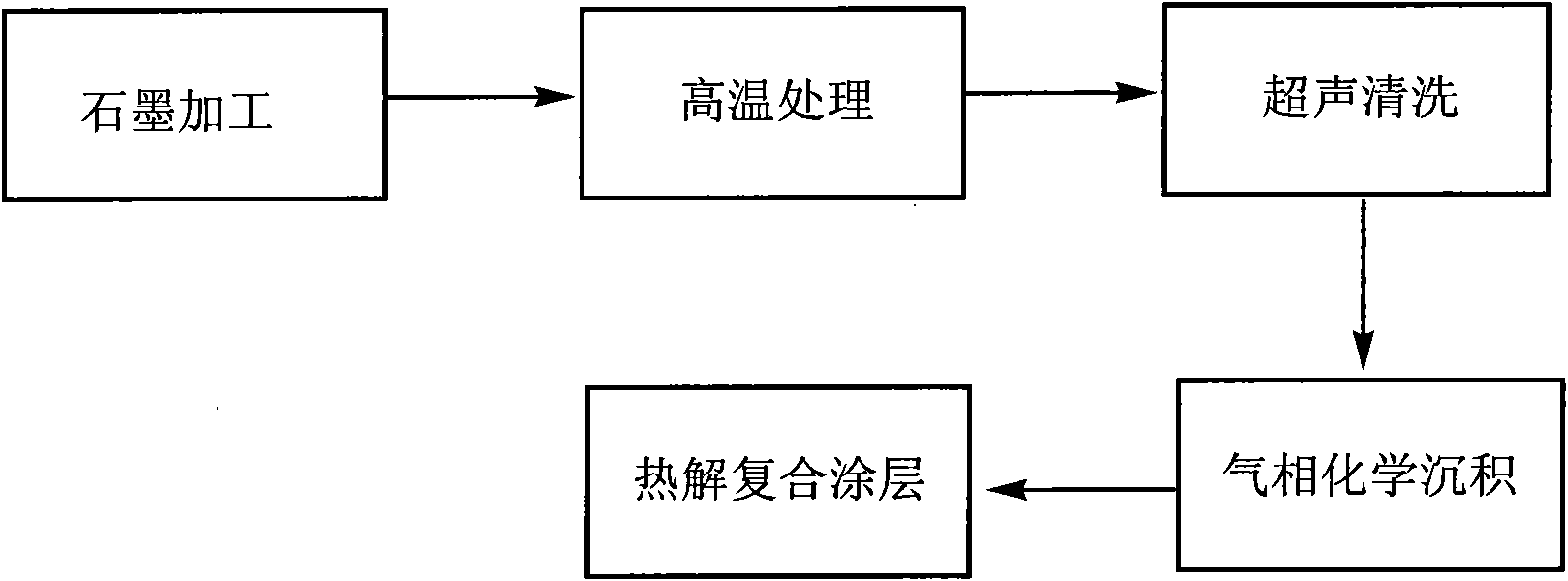

Method used

Image

Examples

Embodiment 1

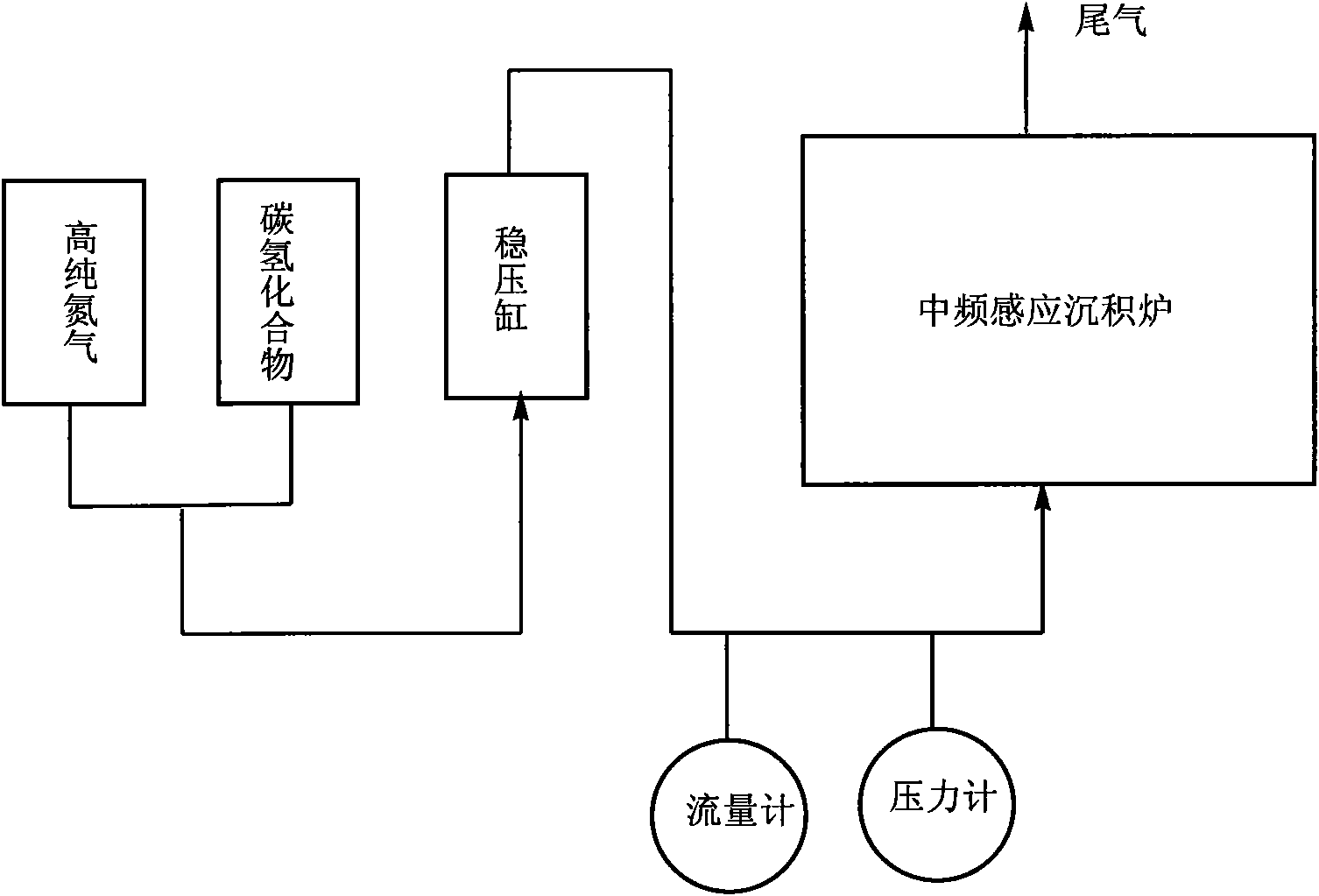

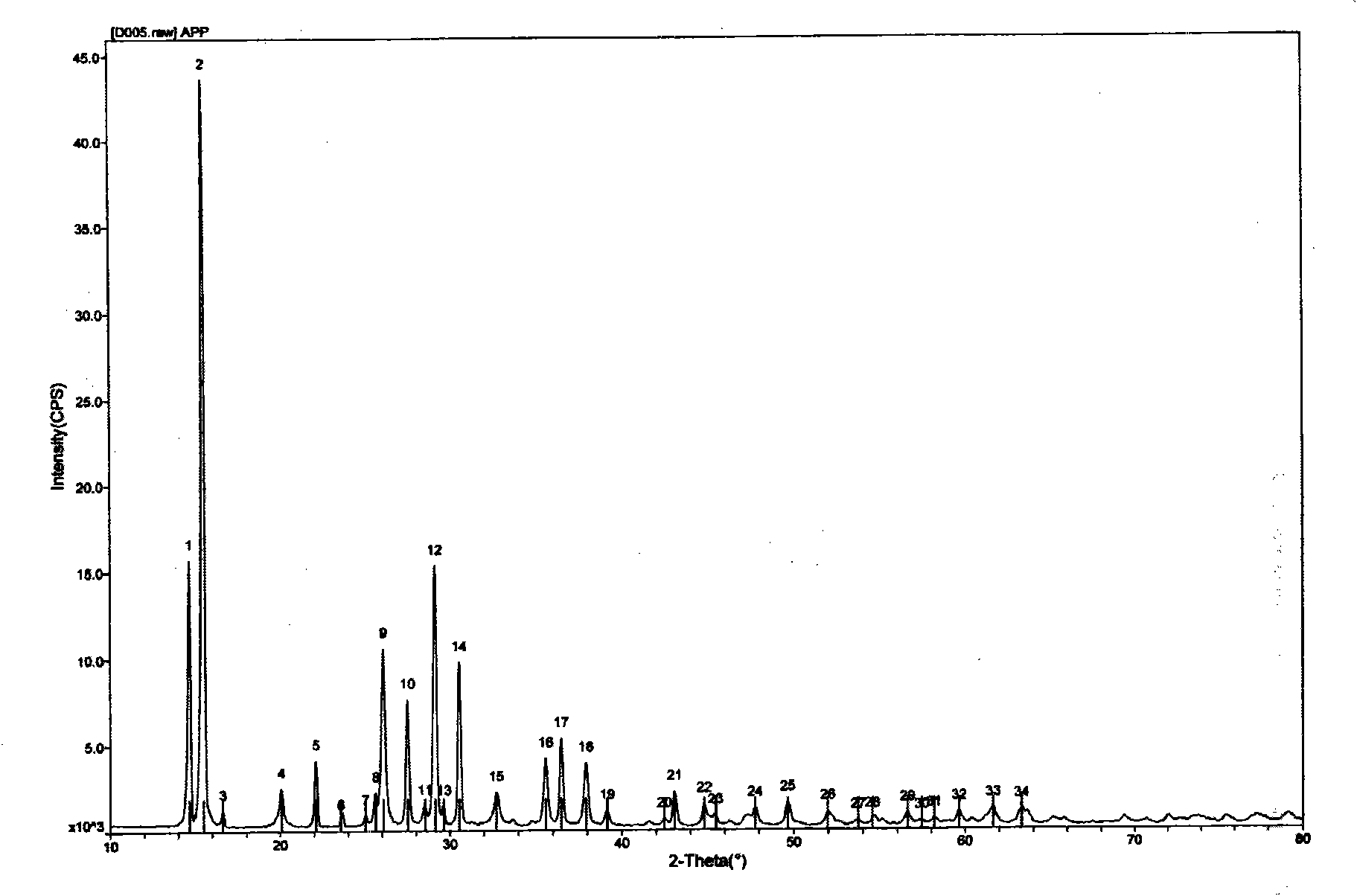

[0038]The machined graphite blank body is placed in an intermediate frequency induction deposition furnace, and the graphite plate on which the coated product is placed is evenly drilled, and the vacuum system is started to make the pressure in the furnace reach a vacuum state. After confirming that there is no leakage in the system, it is powered on for heating To 1700°C, the holding time is 3 hours. When the furnace temperature reaches the specified requirements, turn on the ultrasonic cleaning device to clean the dust and other impurities on the graphite surface, and then feed 99.99% nitrogen and 75% propane in sequence according to the process regulations The hydrocarbon gas is continuously pumped out by the mechanical pump and discharged into the atmosphere. The pressure in the furnace is 4-8mmHg, the deposition time is 2-6 hours, and the cooling time is 3-6 hours. After the ventilation time reaches the process requirements, stop heating, and the furnace chamber is cooled ...

Embodiment 2

[0040] All the other operations are the same as in Example 1, the temperature in the furnace is increased by 100°C to 1800°C, and the holding time is shortened to 2.5 hours. Fill the alkane gas containing 80% propane and 99.99% nitrogen, and keep the rest of the conditions unchanged to prepare pyrolytic graphite coated products.

Embodiment 3

[0042] All the other operations are the same as in Example 1, the temperature in the furnace is increased by 100°C to 1900°C on the basis of Example 2, the holding time is shortened from half an hour to 2 hours on the basis of Example 2, and the furnace is filled with 85% The alkane gas of propane and the nitrogen of 99.99%, keep furnace pressure 6~8mmHg, deposition time 7~14 hours, cooling 6~8 hours, all the other conditions are identical with embodiment 1, make pyrolytic graphite coating product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com