Method for realizing microstructure on pyrolytic graphite chip

A technology of pyrolytic graphite and a realization method, which is applied in the field of micro-electromechanical and achieves the effects of strong bonding force and high relative position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

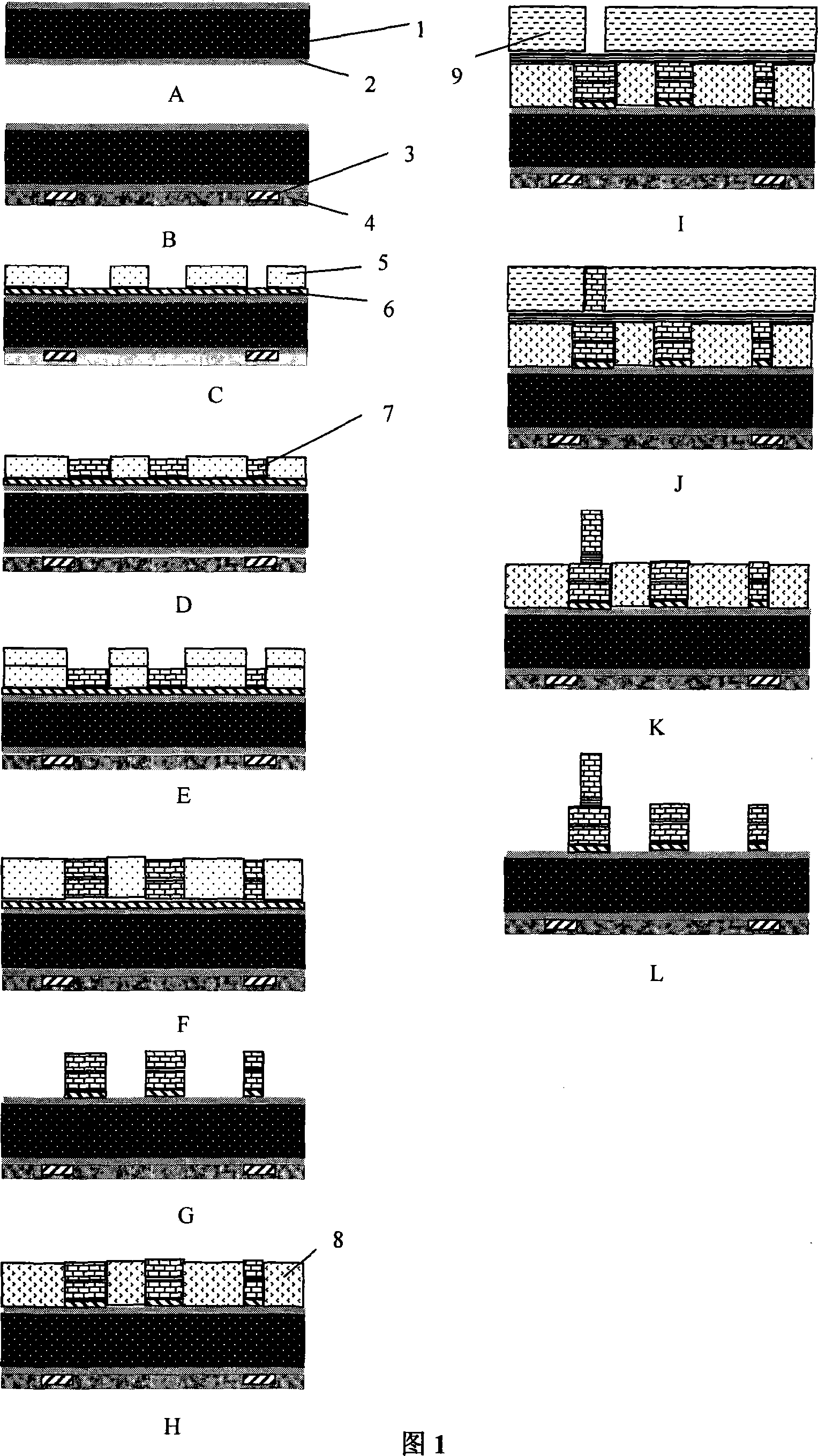

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

[0020] Taking the combination of positive resist AZ P4620 and SU8-100 negative resist process to process the microstructure as an example, the seed layer is made of Cr / Cu metal composite film, the material of the electroplated structural layer is copper (Cu), and a double-sided exposure photolithography machine is used. In the present embodiment, the specific parameter conditions of some processes are: (1) the sputtering seed layer Cr / Cu metal composite film adopts the Z550 type AC and DC magnetron sputtering system of German Leybold-Heraus company, and the basic condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com