Method for coating high temperature-resistant diamond on graphite substrate

A technology of diamond coating and graphite base material, which is applied in the direction of metal material coating process, coating, superimposed layer plating, etc., which can solve the problems of short life of graphite mold, easy occurrence of dust, and lower yield rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] see figure 1 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

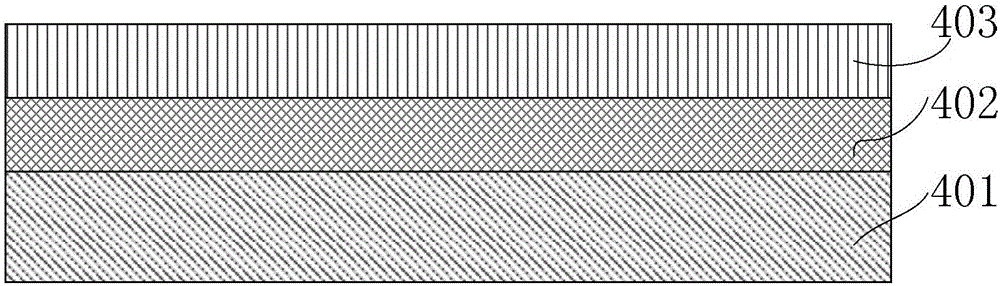

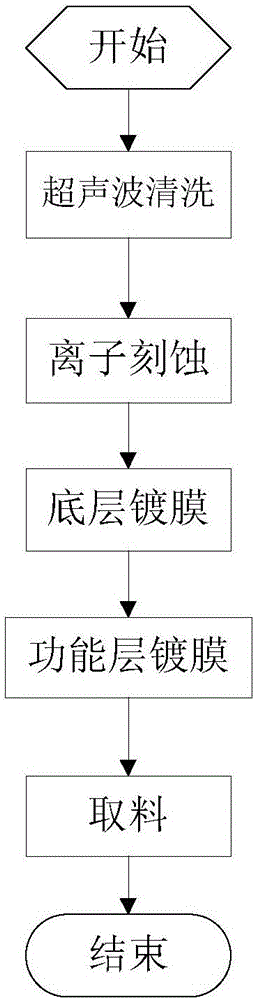

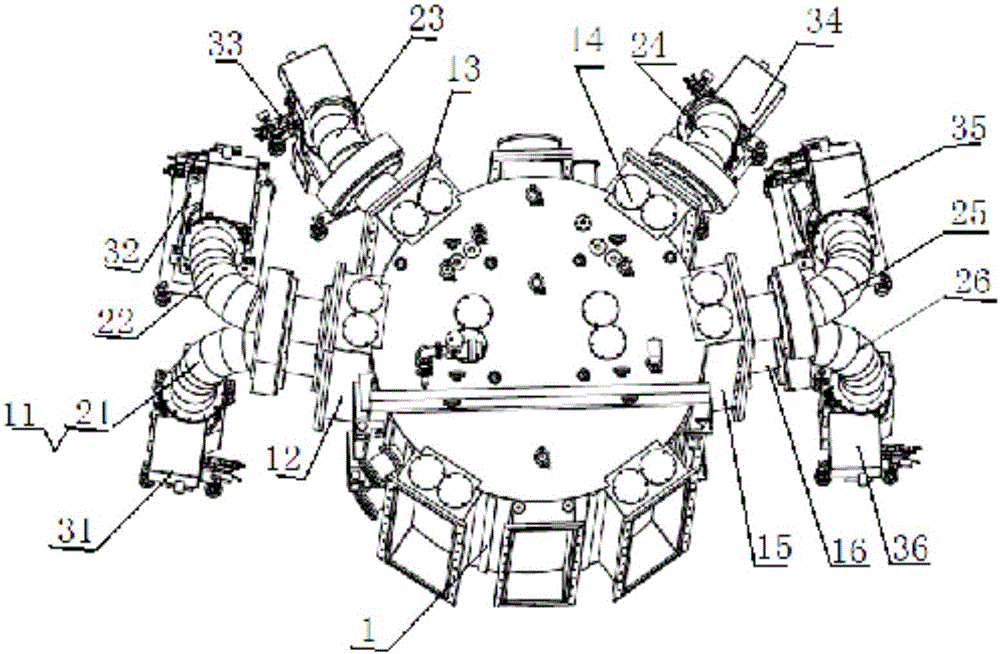

[0033] The diamond-like carbon film prepared by a method of high-temperature-resistant diamond-like carbon coating on a graphite substrate of the present invention includes a bottom layer 402 coated on the surface of a graphite substrate 401 and a functional layer 403 coated on the surface of the bottom layer. The function of the bottom layer 402 is to realize the adhesion of the functional layer 403 on the surface of the graphite substrate 401 and enhance the stability of the functional layer 403 at high temperature. The bottom layer 402 can be one of SiC layer, AlTi layer, AlTiN layer, Si layer or SiN layer, and the coating process adopted is magnetron sputtering process, or multi-arc ion plating process, or vacuum vapor deposition c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com