Lithium-ion battery negative electrode material and preparation method thereof, lithium-ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of affecting the electrochemical performance of negative electrode materials, battery cycle performance degradation, conductive network damage resistance, etc., to improve reversible capacity, The effect of improving the discharge capacity and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method one of lithium ion battery negative electrode material of the present invention comprises the following steps:

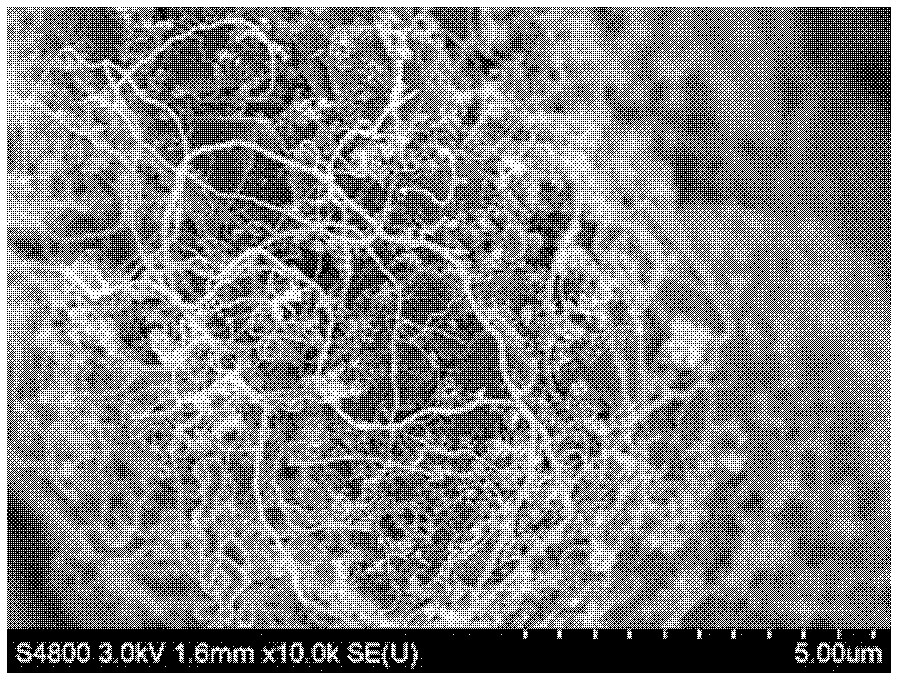

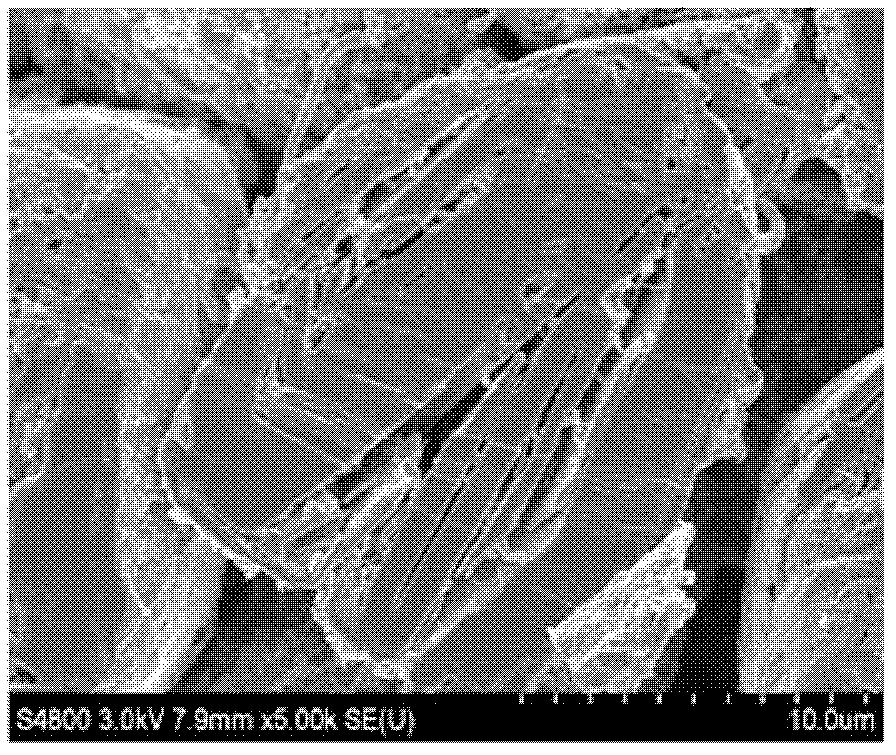

[0035] 1. Mixing, adding a catalyst to the graphite matrix material, the mass of the catalyst is greater than 0 to 5% of the mass of the graphite matrix, and the addition method is solid phase mixing or liquid phase mixing to obtain a mixture. As a carbon source, the catalyst decomposes the active center and the graphite carbon deposition center, and plays a vital role in the morphology and structure of the network carbon nanotubes and / or carbon fibers formed on the surface of the graphite matrix by the cracking products of carbon on the surface of the graphite matrix material. A good catalyst and other conditions of the present invention can form networked carbon nanotubes and carbon fiber structures.

[0036] The graphite matrix is more than one of natural flake graphite, microcrystalline graphite, artificial graphite, carbon micros...

Embodiment 1

[0079] Embodiment 1: the particle size D 50 Spherical natural graphite with a size of 3 to 40 μm and a carbon content of 85% was put into a VC-500 mixer, and 5% of the catalyst Fe(NO 3 ) 3 Solid-phase mixing, rotating speed is 500r / min, mixing time is 180min, obtains mixture; Put mixture in the furnace cavity of rotary furnace, the volume of mixture is 10% of furnace capacity, with 10m 3 The flow rate of / h is fed into nitrogen, the temperature is raised to 1300°C at a speed of 0.1°C / min, and the furnace chamber is rotated at a speed of 20rpm, and kept for 0.5h; 3The carbon source gas methane is fed at a flow rate of / h, and the carbon source gas is stopped after 0.1h (keep 0h under the condition of 1300°C); the temperature is lowered by passing cooling water between the furnace wall and the heat conduction layer in the furnace wall way to below 100°C; continue at 10m 3 The flow rate of / h is passed into nitrogen protection, the temperature is raised to 300°C at a speed of ...

Embodiment 2

[0080] Embodiment 2, the particle size D 50 Spherical natural graphite with a size of 3 to 40 μm and a carbon content of 85% was put into a VC-500 mixer, and 3% of the catalyst Fe(NO 3 ) 3 Solid-phase mixing, the rotating speed is 5000r / min, and the mixing time is 5min to obtain the mixture; the mixture is put into the furnace cavity of the rotary furnace, and the volume of the mixture is 50% of the furnace capacity, and the volume of the mixture is 0.05m 3 The flow rate of / h is fed into nitrogen, and the temperature is raised to 300°C at a rate of 50°C / min, and the furnace chamber is not rotated for 0.1h; 3 The carbon source gas methane is fed at a flow rate of / h, and the carbon source gas is stopped after being kept for 5 hours, and kept at 300°C for 6 hours; naturally cooled to room temperature; 3 The flow rate of / h is fed into nitrogen protection, and the temperature is raised to 3000°C at a rate of 50°C / min and kept for 0.5h. into nitrogen; the material moisture con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com