Preparation method of graphene conductive film

A conductive film, graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problem of high production cost, and achieve the effect of reducing damage, shortening preparation time, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below with reference to the drawings and embodiments.

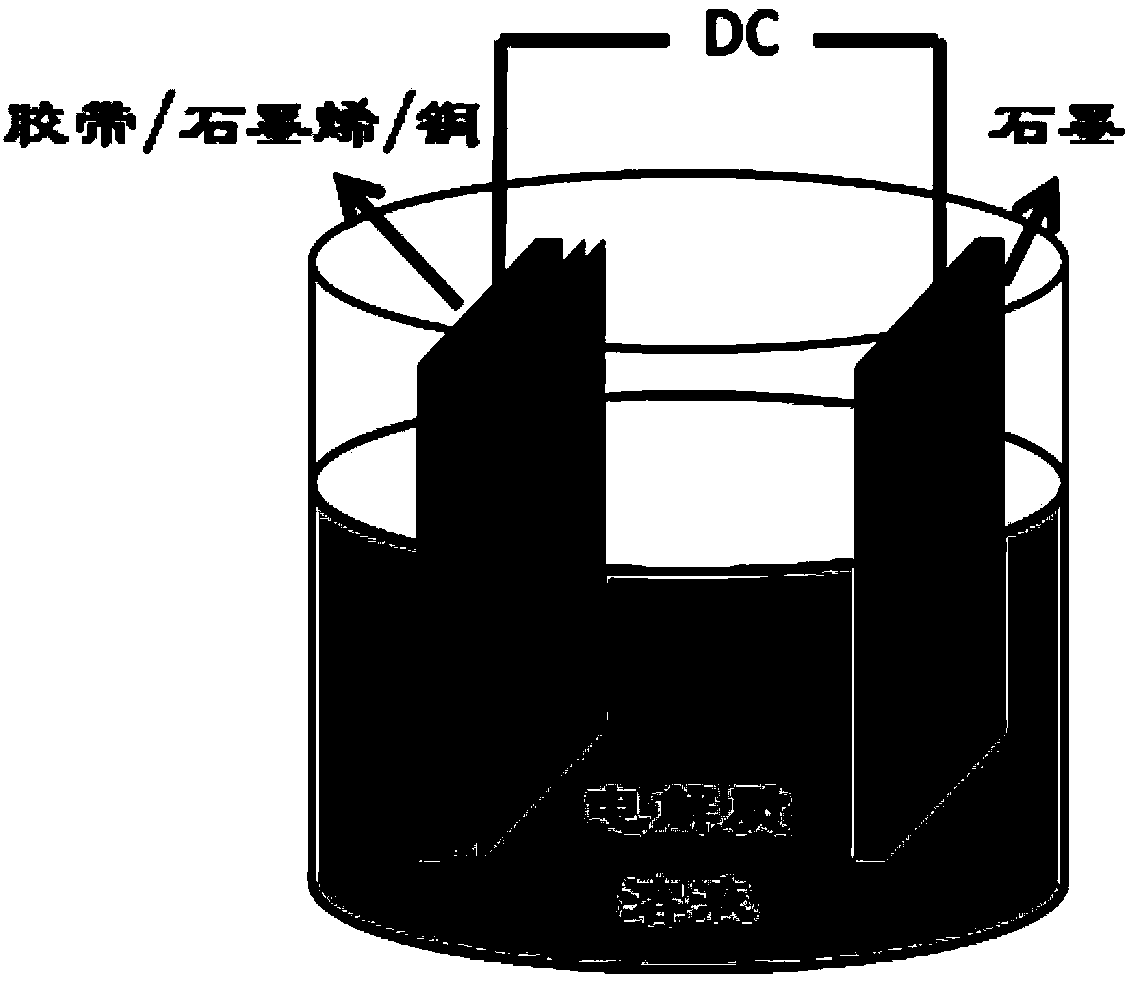

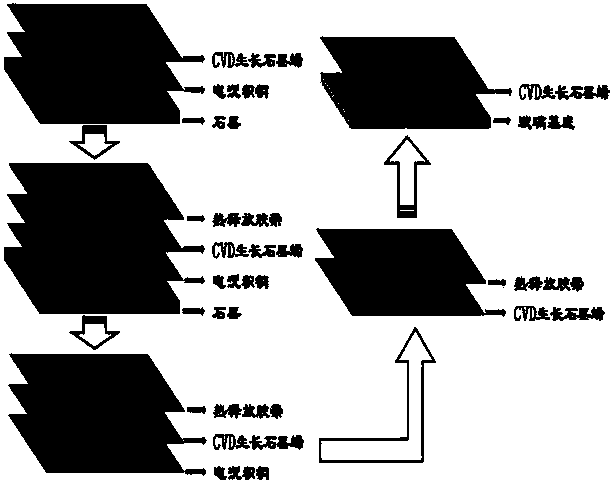

[0021] In the embodiment of the present invention, the copper film obtained by the electrodeposition method on the graphite surface is used as the growth substrate, instead of the growth substrate of the metal copper foil, and the growth of graphene is realized by the CVD method under high temperature conditions; at the same time, the graphite electrode is used as the cathode. The electrochemical corrosion method is used to remove the metal copper, and the copper corrosion and the preparation of the copper film on the graphite surface are carried out simultaneously, which not only greatly reduces the production cost, but also improves the production efficiency.

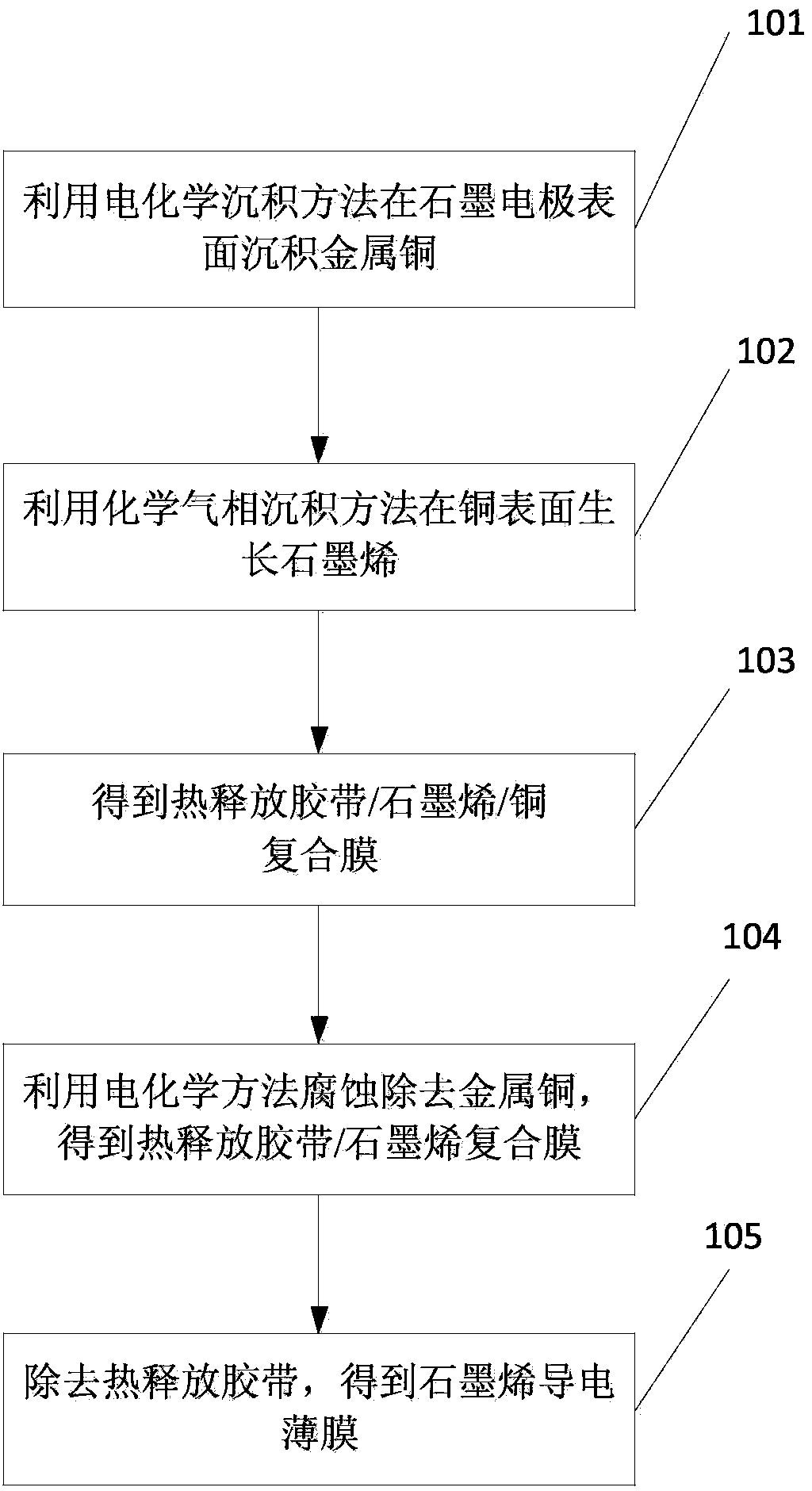

[0022] See figure 1 with figure 2 , The embodiment of the present invention provides a method for preparing a graphene conductive film. The method includes the following steps:

[0023] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| exothermic temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com