Self-supporting silicon carbide nanowire paper and preparing method thereof

A silicon carbide nanowire, self-supporting technology, applied in nanotechnology and other directions, can solve the problems of small area of nanowire paper, and achieve the effects of low equipment requirements, adjustable thickness and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

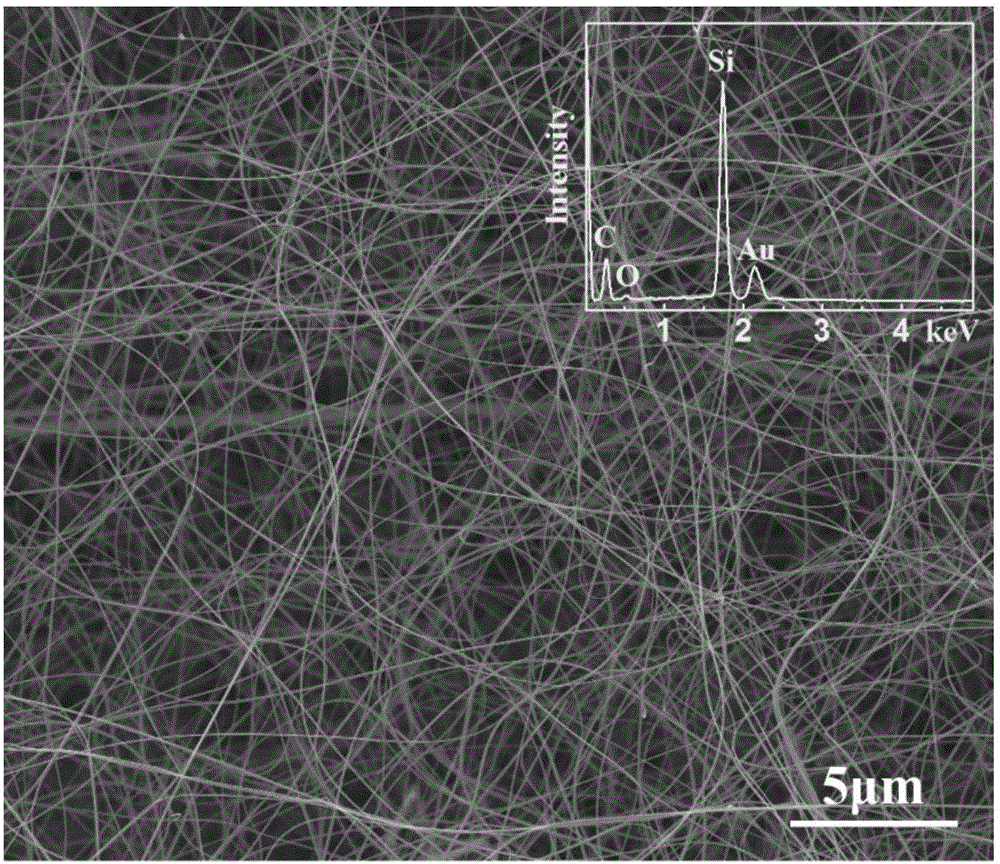

[0033] In this example, a SiC nanowire paper with a thickness of 200 μm is prepared, and the specific steps are as follows:

[0034] 1) Using methyltrimethoxysilane (20wt.%) and dimethyldimethoxysilane (77.9wt.%) as raw materials, using nitric acid as a crosslinking catalyst (0.1wt.%), using a co-hydrolysis method ( The amount of water added is 2wt.%) to prepare a silica gel, and place the prepared gel in an oven at 80° C., keep it warm for 2 hours and dry to obtain a dry gel;

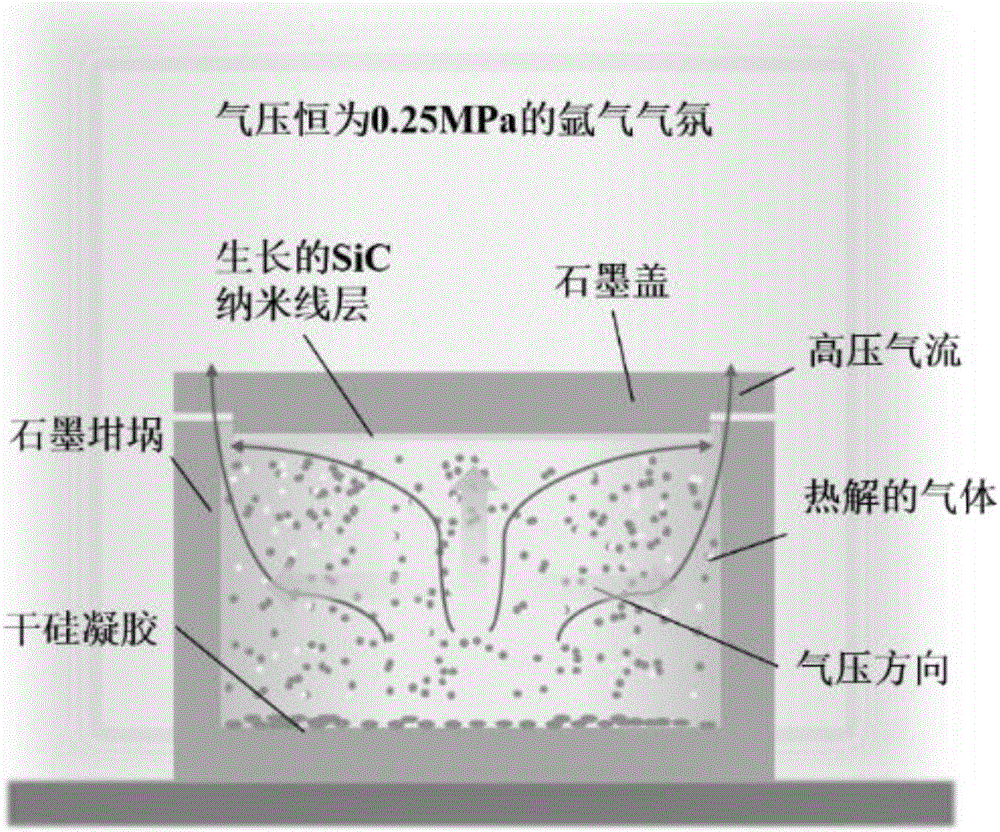

[0035] 2) Put 10g of xerogel into a graphite crucible with a graphite cover, and place it in an air pressure sintering furnace; pump the air pressure of the air pressure furnace to 0.05Pa, and then use high-purity argon (>99.9%) to decompress the air pressure in the furnace. Charge to 0.25MPa, raise the furnace temperature to 1320°C at a rate of 2°C / min and hold for one hour;

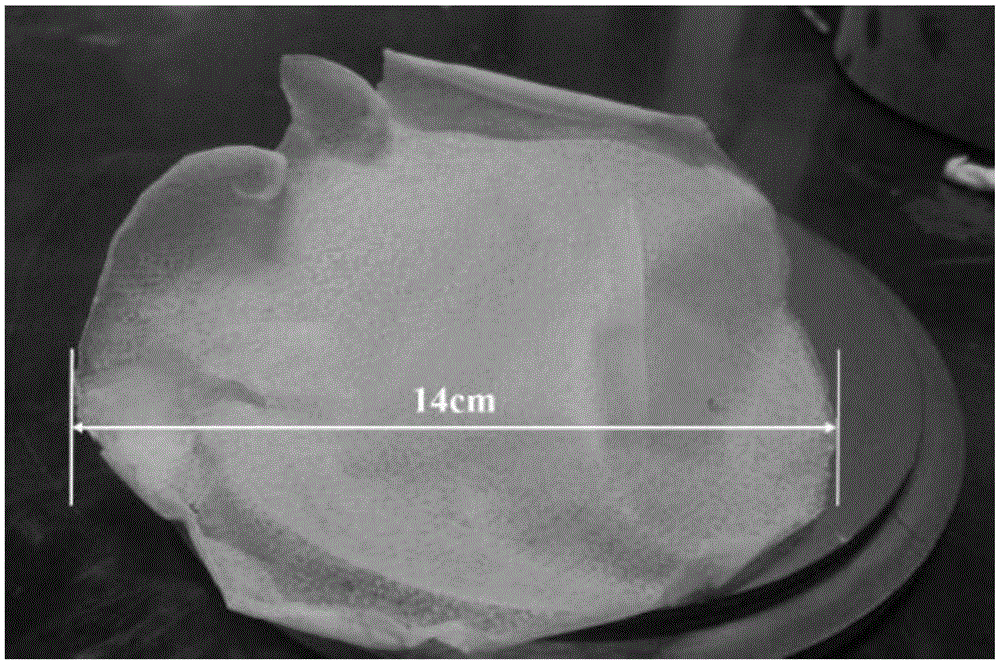

[0036] 3) As the furnace cools down to room temperature, a layer of green nanowire layer grows on the graphite substrate, and...

Embodiment 2

[0038] In this example, a SiC nanowire paper with a thickness of 50 μm is prepared, and the specific steps are as follows:

[0039] 1) Using methyltrimethoxysilane (60wt.%) and dimethyldimethoxysilane (24wt.%) as raw materials, nitric acid (2wt.%) as a cross-linking catalyst, co-hydrolysis (water addition 14wt.%) to prepare silica gel, and place the prepared gel in an oven at 100° C., keep it warm for 2 hours and dry to obtain a dry gel;

[0040] 2) Put 3g of xerogel into a graphite crucible with a graphite cover, and place it in an air pressure sintering furnace; pump the air pressure of the air pressure furnace to 0.01Pa, and then use high-purity argon (>99.9%) to depressurize the furnace Charge to 0.25MPa, raise the furnace temperature to 1450°C at a rate of 5°C / min and hold for one hour;

[0041] 3) As the furnace cools down to room temperature, a green nanowire layer grows on the graphite substrate, and the nanowire layer is peeled off from the graphite substrate to obtain...

Embodiment 3

[0043] In this example, a SiC nanowire paper with a thickness of 100 μm was prepared, and the specific steps were as follows:

[0044] 1) Using methyltrimethoxysilane (45wt.%) and dimethyldimethoxysilane (45wt.%) as raw materials, nitric acid (1wt.%) as a crosslinking catalyst, using co-hydrolysis (water addition The amount is 8wt.%) to prepare silica gel, and place the prepared gel in an oven at 120°C, keep it warm for 2 hours and dry to obtain a xerogel;

[0045] 2) Put 10g of xerogel into a graphite crucible with a graphite cover, and place it in an air pressure sintering furnace; pump the air pressure of the air pressure furnace to 0.008Pa, and then use high-purity argon (>99.9%) to depressurize the air pressure in the furnace. Charge to 0.15MPa, raise the furnace temperature to 1500°C at a rate of 10°C / min and hold for one hour;

[0046] 3) As the furnace cools down to room temperature, a layer of green nanowire layer grows on the graphite substrate, and the nanowire lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com