Preparation method of polystyrene/gold composite microspheres

A technology of polystyrene microspheres and polystyrene, applied in the field of nano-functional materials, can solve the problems of poor bonding, low coverage, time-consuming and laborious, etc., and achieve the effect of dense coating, ensuring uniformity, and simplifying operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

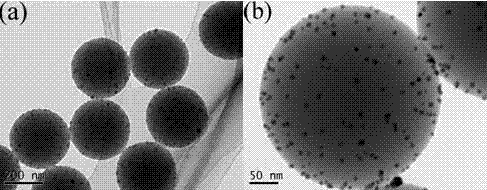

[0032] In a three-necked flask, dissolve 0.0244 g sodium dodecyl sulfate and 0.0222 g potassium persulfate in a mixed solution of ethanol (95%) / water (50ml:20ml), and stir under the protection of argon. Add 1 ml of styrene monomer washed with 10% sodium hydroxide solution dropwise to the solution, heat to 70 °C, and react for 8 h. After the reaction, centrifuge and wash with ethanol for 3 times; use 95% ethanol as a solvent to prepare a 1 mg / ml ethanol solution of polystyrene microspheres. The particle size of the polystyrene microspheres obtained by the reaction is about 300 nm.

[0033]At room temperature, add 0.4 ml of an ethanol solution of 3-aminopropyltriethoxysilane with a volume ratio of 1:49 to 20 ml of a 1 mg / ml polystyrene ethanol solution. Magnetic stirring, reaction 2 h. Aminated polystyrene microspheres were centrifuged and washed with ethanol several times, then dispersed in double distilled water, made into a 1 mg / ml aqueous solution, and allowed to stand for...

Embodiment 2

[0036] Use the 300 nm polystyrene emulsion and the aminated polystyrene aqueous solution in Example 1, let stand for 13 hours, and fully disperse.

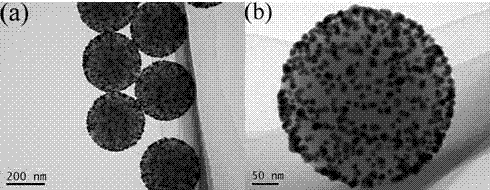

[0037] At room temperature, 0.6 ml of 1 wt% chloroauric acid aqueous solution was added dropwise to the aminated polystyrene aqueous solution, heated to boiling with magnetic stirring, and 2.4 ml of 1 wt% trisodium citrate aqueous solution was added to react for 30 min , the reaction system is dark purple. Polystyrene / gold composite microspheres were centrifuged and washed several times with double distilled water. Transmission electron microscopy showed that the product was gold nanoparticles uniformly and densely attached to the surface of polystyrene microspheres, and the average particle size of gold nanoparticles was 8.0±2.0 nm. And the number of gold colloid particles adsorbed on the surface of a single polystyrene microsphere is about 413.

Embodiment 3

[0039] Use the 300 nm polystyrene emulsion and the aminated polystyrene aqueous solution in Example 1, let stand for 22 hours, and fully disperse.

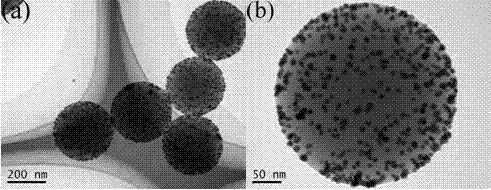

[0040] At room temperature, add 0.2 ml of 1 wt% chloroauric acid aqueous solution dropwise to the aminated polystyrene aqueous solution, stir magnetically and heat up to boiling, add 0.8 ml of 1 wt% trisodium citrate aqueous solution, and react for 30 min , the reaction system is purple. Polystyrene / gold composite microspheres were centrifuged and washed several times with double distilled water. Transmission electron microscopy showed that the product was gold nanoparticles uniformly attached to the surface of polystyrene microspheres, and the average particle size of gold nanoparticles was 6.5±1.8 nm. And the number of gold colloid particles adsorbed on the surface of a single polystyrene microsphere is about 140.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com