Preparation method of calcium carbonate whisker with continuously controllable morphology

A calcium carbonate whisker and morphology technology, applied in the field of calcium carbonate whisker preparation, can solve the problems of low production cost and high cost hindering large-scale application, and achieve increased growth points, good chemical properties and mechanical properties, and effects strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Add calcium oxide to deionized water to obtain Ca(OH) with a concentration of 0.1mol / L 2 Suspension, heated to 70°C at the same time, digested for 2h;

[0023] Step 2: Weigh magnesium chloride as the crystal form control agent, make the ratio of magnesium to calcium 1:1, add water to dissolve, and add the magnesium chloride solution to the digested Ca(OH) 2 In the suspension, stir for 0.5h to make it uniform; Step 3: use a three-neck round bottom flask, and pass CO2 through the openings on both sides at a flux of 150ml / min 2 Gas to the bottom of the reaction device for carbonation reaction;

[0024] Step 4: After the carbonization reaction was carried out for 2 hours, the obtained precipitate was suction-filtered, washed, and dried to obtain a sample.

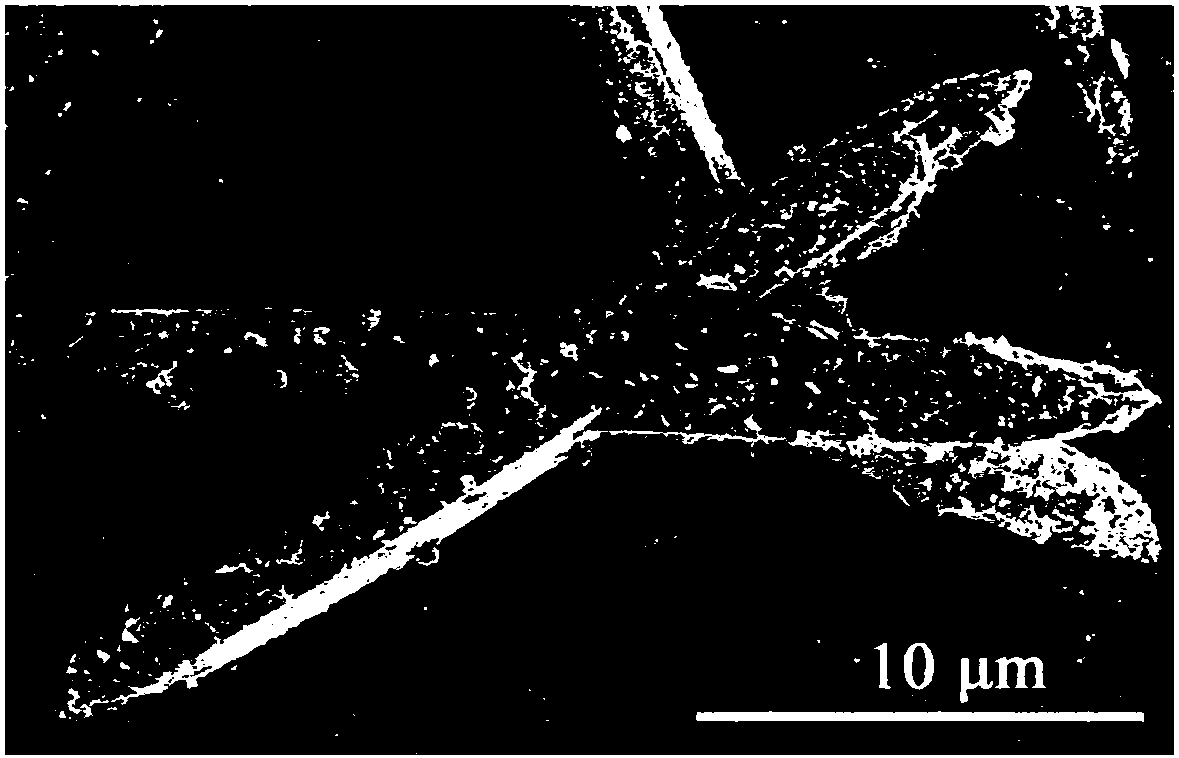

[0025] The number of branches of the prepared calcium carbonate whiskers is mainly 4, and its SEM image is shown in figure 1 .

Embodiment 2

[0027] Step 1: Add calcium oxide to deionized water to obtain Ca(OH) with a concentration of 0.2mol / L 2 Suspension, heated to 80°C at the same time, digested for 2 hours;

[0028] Step 2: Weigh magnesium chloride as the crystal form control agent, make the ratio of magnesium to calcium 2:1, add water to dissolve, and add the magnesium chloride solution to the digested Ca(OH) 2 In the suspension, stir for 0.5h to make it uniform; Step 3: use a three-necked round bottom flask, and pass CO2 through the openings on both sides at a flux of 100ml / min 2 Gas to the bottom of the reaction device for carbonation reaction;

[0029] Step 4: The carbonization reaction ends after 2.5 hours, and the obtained precipitate is suction filtered, washed, and dried to obtain a sample.

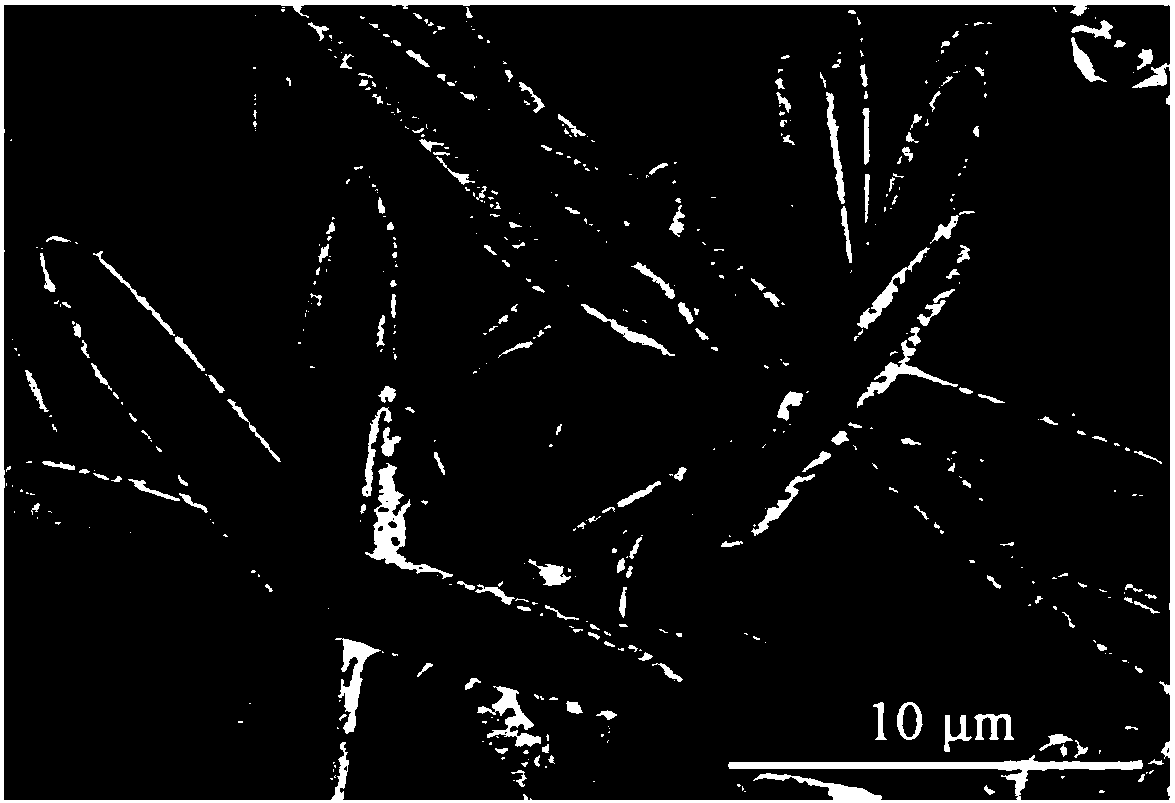

[0030] The number of branches of the prepared calcium carbonate whiskers is mainly about 7, and the SEM image is shown in figure 2 .

Embodiment 3

[0032] Step 1: Add calcium oxide to deionized water to obtain Ca(OH) with a concentration of 0.3mol / L 2 Suspension, heated to 100°C at the same time, digested for 2 hours;

[0033] Step 2: Weigh magnesium chloride as the crystal form control agent, make the ratio of magnesium to calcium 2.5:1, add water to dissolve, and add the magnesium chloride solution to the digested Ca(OH) 2 In the suspension, stir for 0.5h to make it uniform;

[0034] Step 3: Using a three-neck round bottom flask, inject CO from both sides at a flow rate of 60ml / min 2 Gas to the bottom of the reaction device for carbonation reaction;

[0035] Step 4: The carbonization reaction is completed after 3 hours, and the obtained precipitate is suction filtered, washed, and dried to obtain a sample.

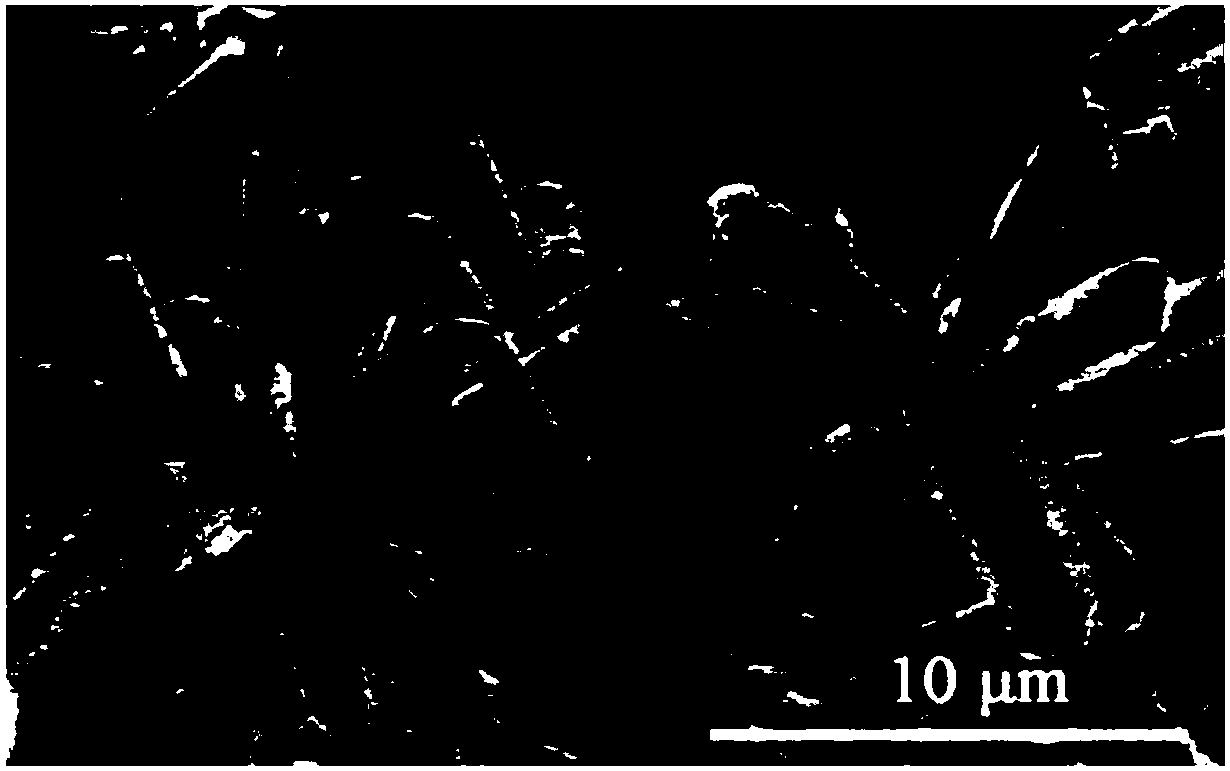

[0036] The number of branches of the prepared calcium carbonate whiskers can be as high as 16, and the SEM images of the whiskers are shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com