A kind of diamond substrate and preparation method thereof

A technology for diamond and diamond micropowder is applied in the field of diamond substrate and its preparation, which can solve the problem of high price of single crystal diamond, and achieve the effects of high mechanical strength, increased growth rate, and improved deposition quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The invention provides a method for preparing a novel diamond substrate, which specifically includes the following steps:

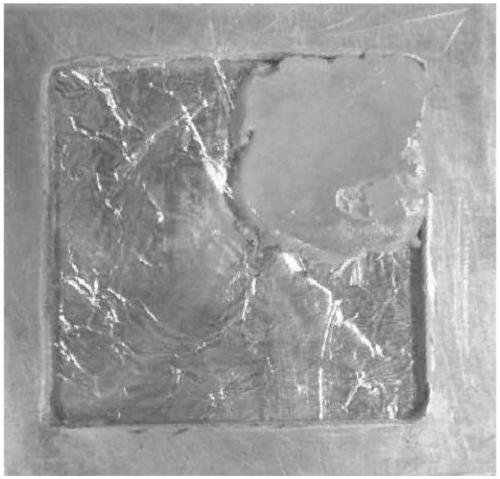

[0052] 1) First weigh 1.5g of diamond powder with a particle size of 2μm, and then weigh 0.3g of the prepared polyimide solution with a mass fraction of 7.5%, so that the diamond powder accounts for the total amount of diamond powder and polyimide. The percentage of mass is 98.5%, figure 1 ;

[0053]Polyimide solution: Produced by Changzhou Furunte Plastic New Material Co., Ltd. (thermoplastic PAA-1), the solvent is N-methylpyrrolidone (NMP), the solid content is 19%, environmental protection, non-dangerous goods, adhesive high sex.

[0054] 2) Mix the above mixed mixture in a DAC 150.1 FVZ type mixer, the mixing time is 1min, and the mixing speed is 3000r / min;

[0055] 3) Put the above mixed mixture into a size of 30×30mm 2 In the aluminum sheet-tin foil mold, the aluminum sheet and the tin foil mold have been cleaned with alcohol before use....

Embodiment 2

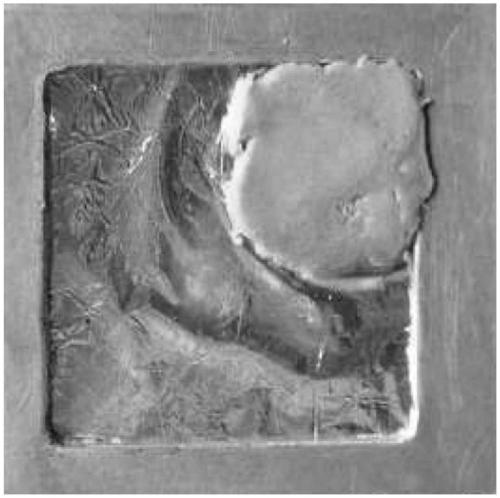

[0062] 1) First weigh 1.5g of diamond powder with a particle size of 20μm, and then weigh 0.3g of the prepared polyimide solution with a mass fraction of 7.5%, so that the diamond powder accounts for the total amount of diamond powder and polyimide. The percentage of mass is 98.5% (this ratio is one of the more ideal ratios obtained through experiments conducted at different mass ratios, and the fluctuation range of this ratio can be considered ideal within the range of 98.5% ± 0.5%) ;

[0063] 2) Put the above mixed mixture into a mixer for mixing, the mixing time is 1min, and the mixing speed is 3000r / min;

[0064] 3) Put the above mixed mixture into a size of 30×30mm 2 In the aluminum sheet-tin foil mold, the aluminum sheet and the tin foil mold have been cleaned with alcohol before use;

[0065] 4) Put the mold containing the mixture into the oven. Since the adhesive used is polyimide adhesive, according to the relevant literature research and the verification process of...

Embodiment 3

[0071] 1) First weigh 1.5g of diamond powder with a particle size of 200μm, and then weigh 0.2g of the prepared polyimide solution with a mass fraction of 7.5%, so that the diamond powder accounts for the total amount of diamond powder and polyimide. The percentage of mass is 99%;

[0072] 2) Put the above mixed mixture into the mixer and mix it for 1min, and the mixing speed is 3000r / min;

[0073] 3) Put the above mixed mixture into a size of 30×30mm 2 In the aluminum sheet-tin foil mold, the aluminum sheet and the tin foil mold have been cleaned with alcohol before use;

[0074] 4) Put the mold containing the mixture into the oven. Since the adhesive used is polyimide adhesive, according to the relevant literature research and the verification process of this experiment, the temperature rise program is set as shown in Table 1;

[0075] 5) Demoulding the solidified diamond and polyimide mixture;

[0076] 6) Grind the above-mentioned mixture after demoulding on SiC sandpape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com