Method for extracting kaempferol

An extraction method and technology for kaempferol, applied in the field of extraction of kaempferol, can solve the problems of poor solubility, less extraction of kaempferol, product loss, etc., and achieve the effects of improving the utilization rate of raw materials, improving the extraction rate and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

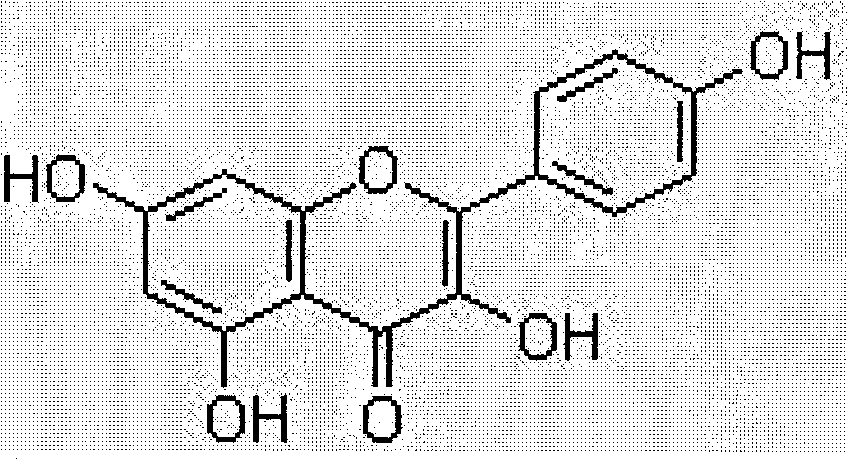

Image

Examples

Embodiment 1

[0030] Grind 10kg of raw materials (2.4% equivalent content of kaempferol and its derivatives), add 80L of 1% lime water, stir and heat in a boiling water bath for 1.5 hours, cool; add phosphoric acid to the filtrate to adjust pH to 5, filter, add 50g of fiber Suzyme, heat up to 40°C in a stirring heating device, stabilize for 15 hours and hydrolyze to obtain 84L hydrolyzate; heat and concentrate the hydrolyzate to 8L, add ethyl acetate to stir and extract, take the ester phase and recover ethyl acetate under reduced pressure to obtain 487g Extraction: use 2L 95% methanol for the extract, and finally obtain 210g of kaempferol finished product with a content of 99.1%.

Embodiment 2

[0032] Grind 10kg of raw materials (the equivalent content of kaempferol and its derivatives is 3.1%), add 90L of 1.5% lime water, stir and heat in a boiling water bath for 1.7 hours, and cool; add phosphoric acid to the filtrate to adjust the pH to 6, filter, and add 75g of fiber Suzyme, heat up to 45°C in a stirring heating device, stabilize for 18 hours and hydrolyze to obtain 95L hydrolyzate; heat and concentrate the hydrolyzate to 8L, add ethyl acetate to stir and extract, take the ester phase and recover ethyl acetate under reduced pressure to obtain 496g Extract: 2.5L 85% methanol is used for the extract to finally obtain 274g of kaempferol finished product with a content of 98.3%.

Embodiment 3

[0034] Grind 10kg of raw materials (2.7% equivalent content of kaempferol and its derivatives), add 100L of 1.5% lime water, stir and heat in a boiling water bath for 2 hours, cool; add acetic acid to the filtrate to adjust the pH to 7, filter, add 100g of fiber Suzyme, heat up to 50°C in a stirring heating device, stabilize for 20 hours and hydrolyze to obtain 107L hydrolyzate; heat and concentrate the hydrolyzate to 7L, add ethyl acetate to stir and extract, take the ester phase and recover ethyl acetate under reduced pressure to obtain 491g Extract: use 3L 80% methanol for the extract, and finally obtain 243g of kaempferol finished product with a content of 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com