Austenite grain size refining control method for high-temperature carburized gear steel

An austenite grain, high-temperature carburizing technology is applied in the metallurgical field to achieve the effects of excellent processing performance and service performance, good austenite grain size stability, and a simple and easy control method for grain size refinement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

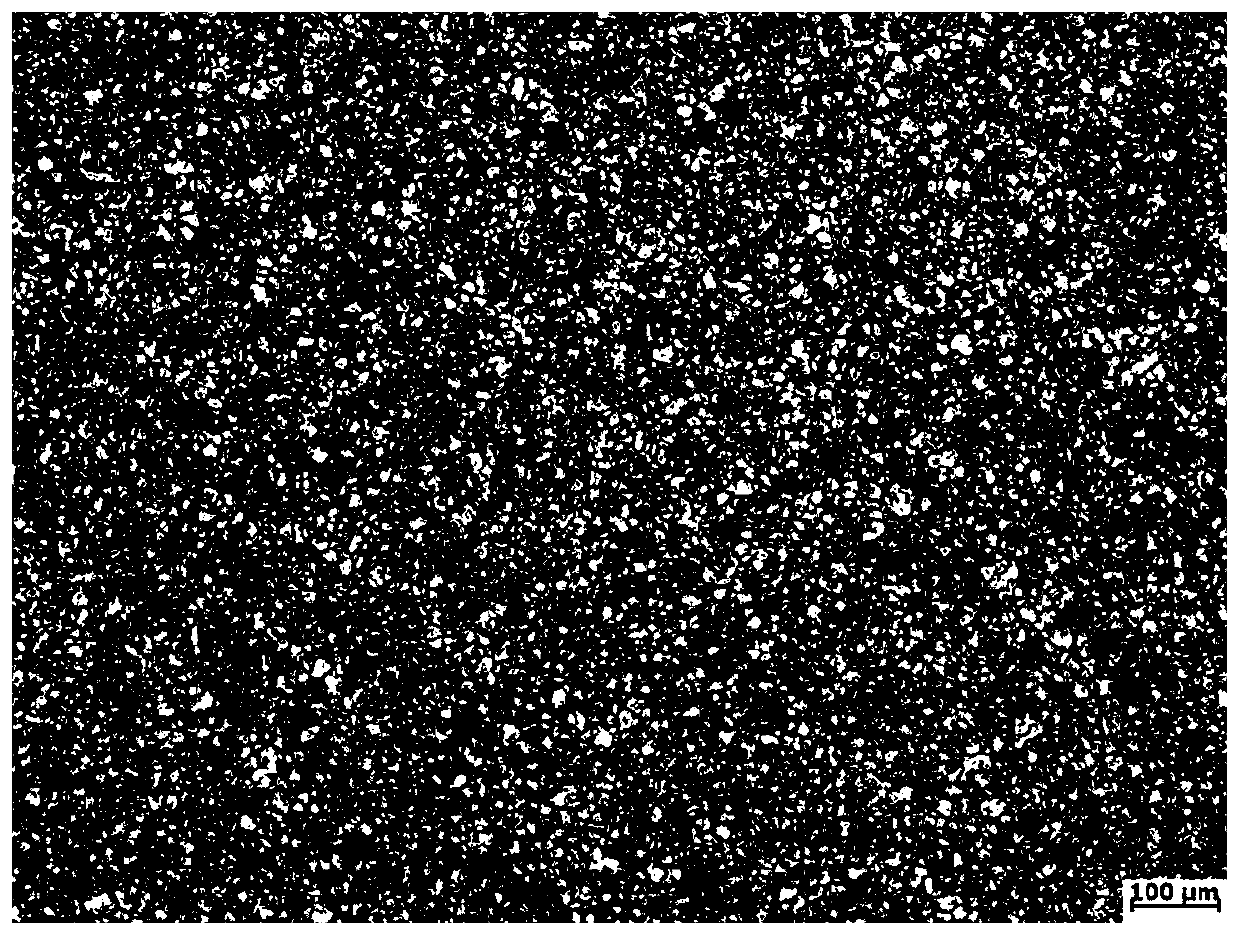

[0018] Take the specification Bars for gear steel, including the following components by weight percentage: C: 0.20%, Mn: 0.75%, Si: 0.15%, P: 0.010%, S: 0.005%, Cr: 0.50%, Ni: 0.55%, Mo: 0.19%, Al: 0.025%, N: 0.018, and the rest are Fe and unavoidable impurities. Through EAF smelting, LF refining, VD vacuum degassing, continuous casting, slab slow cooling, primary heating, billet rolling, billet dephosphorization, secondary heat rolling heating, secondary heat rolling dephosphorization, final rolling, slow The gear steel prepared by cooling, straightening, peeling, ultrasonic flaw detection, and magnetic flux leakage flaw detection, the photo of the austenite grain after being corroded by saturated picric acid is as follows figure 1 shown.

[0019] Among them, EAF smelting: oxygen blowing slagging, control of electric furnace endpoint C 0.06%, P 0.007%, tapping temperature 1620°C, deoxidation and alloying operations during tapping.

[0020] LF refining: Add aluminum block...

Embodiment 2

[0030] Take the specification Bars for gear steel, including the following components by weight percentage: C: 0.23%, Mn: 0.90%, Si: 0.20%, P: 0.012%, S: 0.030%, Cr: 0.40%, Ni: 0.70%, Mo: 0.15%, Al: 0.040%, N: 0.015, and the rest are Fe and unavoidable impurities. After EAF smelting, LF refining, VD vacuum degassing, continuous casting, slab slow cooling, primary heating, billet rolling, billet dephosphorization, secondary heat rolling heating, secondary heat rolling dephosphorization, final rolling, slow The gear steel is prepared by cooling, straightening, peeling, ultrasonic flaw detection, and magnetic flux leakage flaw detection.

[0031] Among them, EAF smelting: oxygen blowing slagging, control of electric furnace end point C 0.07%, P 0.010%, tapping temperature 1600°C, deoxidation and alloying operations during tapping.

[0032] LF refining: the aluminum content in the molten steel is reduced to 0.010% by adding aluminum blocks, adding slagging materials for pre-sla...

Embodiment 3

[0042] Take the specification Bars for gear steel, including the following components by weight percentage: C: 0.18%, Mn: 0.70%, Si: 0.35%, P: 0.020%, S: 0.035%, Cr: 0.60%, Ni: 0.40%, Mo: 0.25%, Al: 0.044%, N: 0.014, and the rest are Fe and unavoidable impurities. After EAF smelting, LF refining, VD vacuum degassing, continuous casting, slab slow cooling, primary heating, billet rolling, billet dephosphorization, secondary heat rolling heating, secondary heat rolling dephosphorization, final rolling, slow The gear steel is prepared by cooling, straightening, peeling, ultrasonic flaw detection, and magnetic flux leakage flaw detection.

[0043] Among them, EAF smelting: oxygen blowing slagging, control of electric furnace end point C 0.10%, P 0.015%, tapping temperature 1650°C, deoxidation and alloying operations during tapping.

[0044] LF refining: Add aluminum blocks to make the aluminum content in molten steel 0.045%, add slagging materials for pre-slagging, and keep whit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com