Ceramic casting system

A casting system and ceramic technology, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problems affecting the appearance quality and processing performance of castings, sand casting system erosion, long casting time, etc., to achieve good feeding and The effects of transmitting static pressure, purifying molten iron, and facilitating manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

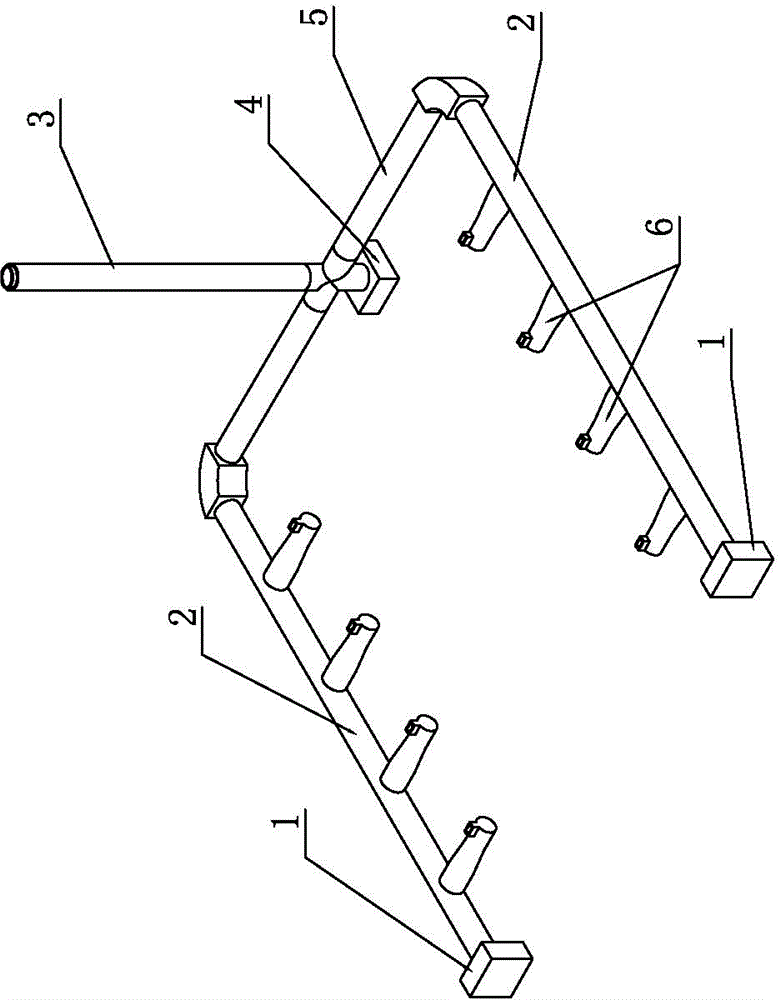

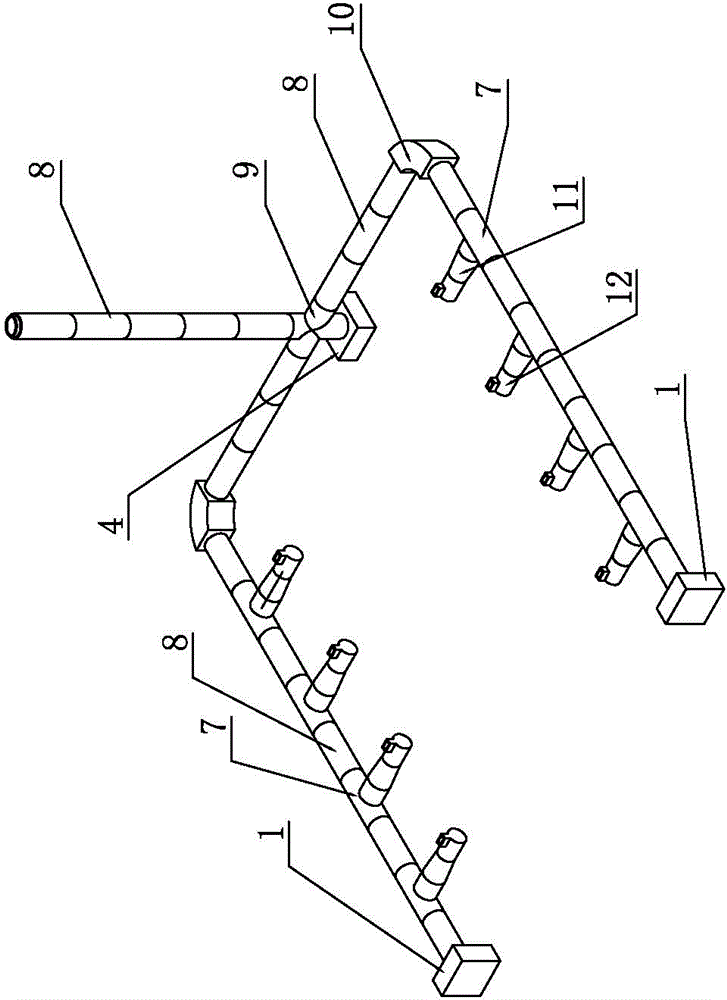

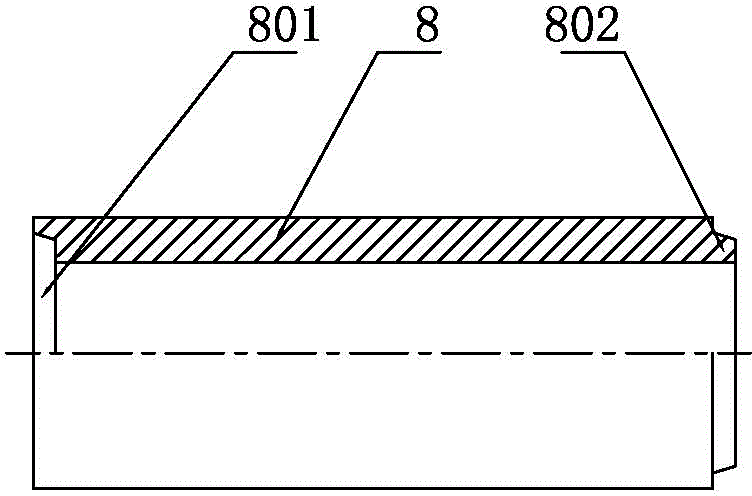

[0023] Such as Figure 1-12 As shown, it is a ceramic casting system, including a sprue 3, a runner and an ingate 6, the sprue 3 is set upright, the runner is set horizontally, and the bottom of the sprue 3 is connected to the ingate through the runner The sprue 3, the runner and the inrunner 6 are made of ceramic materials such as several equal-diameter straight pipes 8, four-way pipes 9, bent pipes 10, variable-diameter straight pipes 11, three-way pipes 7 and flat mouth Tubes 12 are connected; the runner includes a connected runner inlet section 2 and a runner outlet section 5, and the sprue 3 and runner inlet section 2 are sequentially connected by a plurality of equal-diameter straight pipes 8; The four-way pipe 9 has four openings, which are respectively upward openings, openings on both sides and downward openings. The upward opening of the four-way pipe 9 is connected to the lower end of the sprue 3, and the downward opening of the four-way pipe 9 is provided with Blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com