Inoculant for nodular cast iron flywheel shell and preparation method of inoculant

A ductile iron and inoculant technology, applied in the metallurgical field, can solve the problems of high carbon content and hardness, rapid inoculation recession, serious segregation, etc., and achieve the effect of improving the strength of the matrix, promoting the formation of ferrite, and having good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

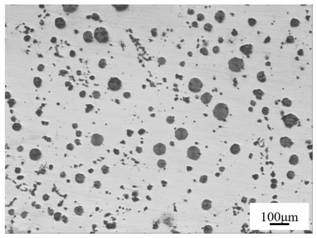

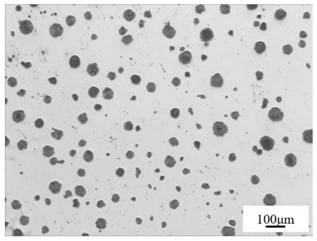

Image

Examples

Embodiment 1

[0029] The nodular cast iron inoculant used in the present invention contains the following components in weight percent: 70% silicon, 2% niobium, 0.5% yttrium, and the rest is Fe.

[0030] The above-described preparation method for nodular cast iron inoculant comprises the following specific steps:

[0031] S1. Weigh each raw material according to the proportion after drying;

[0032] S2, fully mixing the weighed raw materials at 1500°C and then sintering;

[0033] S3, adding the sintered inoculant into a ball mill for ball milling and mixing for 60 minutes, and pulverizing into a powder with an average particle size of about 500 μm;

[0034] S4. After passing the quality inspection, it is sealed and packaged for later use.

[0035] The above-described method for using the nodular cast iron inoculant comprises the following specific steps:

[0036] S1, drying the inoculant;

[0037] S2. After the molten iron is melted, the furnace temperature is 1500°C, and it is spheroid...

Embodiment 2

[0044] The inoculant used in the present invention for ductile iron contains the following components in weight percent: 65% silicon, 1% niobium, 0.2% yttrium, and the rest is Fe.

[0045] The above-described preparation method for nodular cast iron inoculant comprises the following specific steps:

[0046] S1. Weigh each raw material according to the proportion after drying;

[0047] S2, fully mixing the weighed raw materials at 1500°C and then sintering;

[0048] S3, adding the sintered inoculant into a ball mill for ball milling and mixing for 30 minutes, and pulverizing into a powder with an average particle size of about 400 μm;

[0049] S4. After passing the quality inspection, it is sealed and packaged for later use.

[0050] The above-described method for using the nodular cast iron inoculant comprises the following specific steps:

[0051] S1, drying the inoculant;

[0052] S2. After the molten iron is melted, the furnace temperature is 1520°C, and it is spheroidi...

Embodiment 3

[0058] The inoculant used for the ductile iron in the present invention contains the following components in weight percent: 60% silicon, 3% niobium, 0.5% yttrium, and the rest is Fe.

[0059] The above-described preparation method for nodular cast iron inoculant comprises the following specific steps:

[0060] S1. Weigh each raw material according to the proportion after drying;

[0061] S2, fully mixing the weighed raw materials at 1500°C and then sintering;

[0062] S3, adding the sintered inoculant into a ball mill for ball milling and mixing for 60 minutes, and pulverizing into a powder with an average particle size of about 600 μm;

[0063] S4. After passing the quality inspection, it is sealed and packaged for later use.

[0064] The above-described method for using the nodular cast iron inoculant comprises the following specific steps:

[0065] S1, drying the inoculant;

[0066] S2. After the molten iron is melted, the furnace temperature is 1510°C, and it is spheroi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com