Low activation steel and making method thereof

A low-activation steel and steel ingot technology, applied in the field of materials, can solve the problems of high temperature mechanical properties deterioration, material failure and other problems, and achieve the effect of improving mechanical properties and radiation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 (Influence of Composition Design on Performance)

[0043] Preparation:

[0044] Qualified low-activation steel was prepared by adopting the composition of the present invention, and its composition is: C: 0.085% by weight; N: 0.028% by weight; Ta: 0.035% by weight; Mn: 0.51% by weight; W: 1.51% by weight; Cr: 9.12% by weight; V: 0.24% by weight; total amount of P and S: ≤0.010% by weight; the rest is Fe. After casting, forging and rolling the raw materials of the above ingredients into 16 mm steel plates (the effective thickness is 16), the following heat treatment process is adopted: at 1000 ° C for 45 minutes, and then moved to another temperature of 855 ° C ~ 860 ° C ℃ furnace for 30 minutes, air-cooled to room temperature; then heated to 750 ℃ ~ 755 ℃ tempering 75 minutes, air-cooled to room temperature.

[0045] Evaluation indicators:

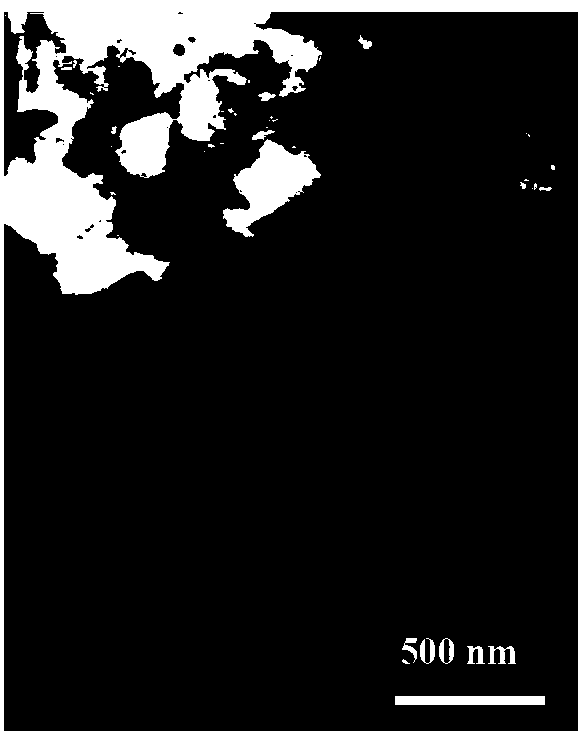

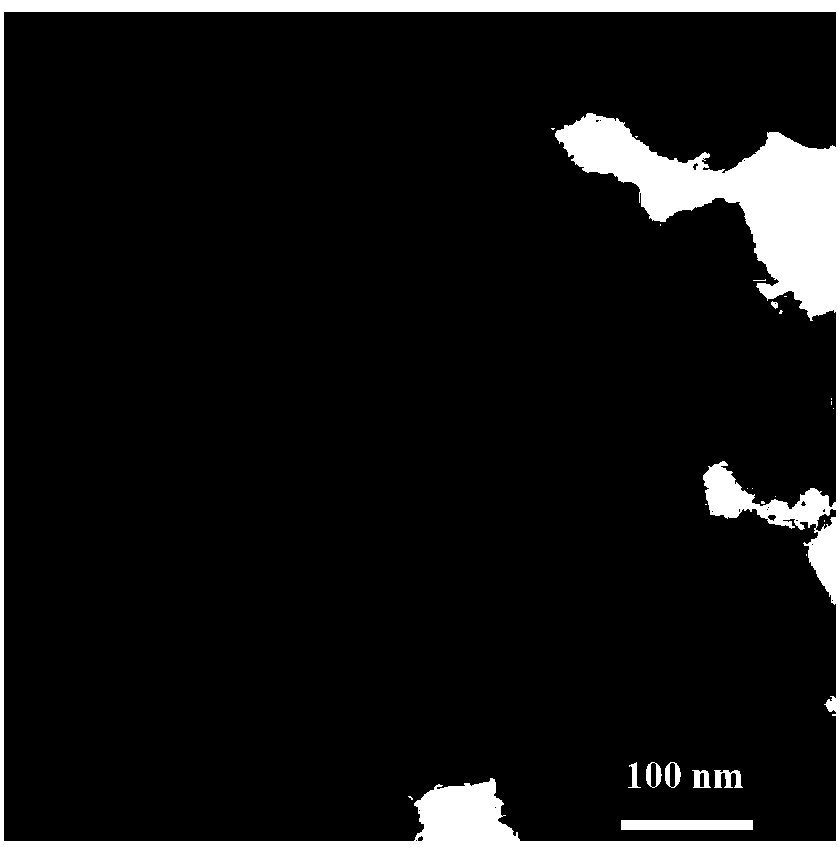

[0046] The microstructure and morphology diagram of the steel alloy prepared by the above-mentioned embodiment meth...

Embodiment 2

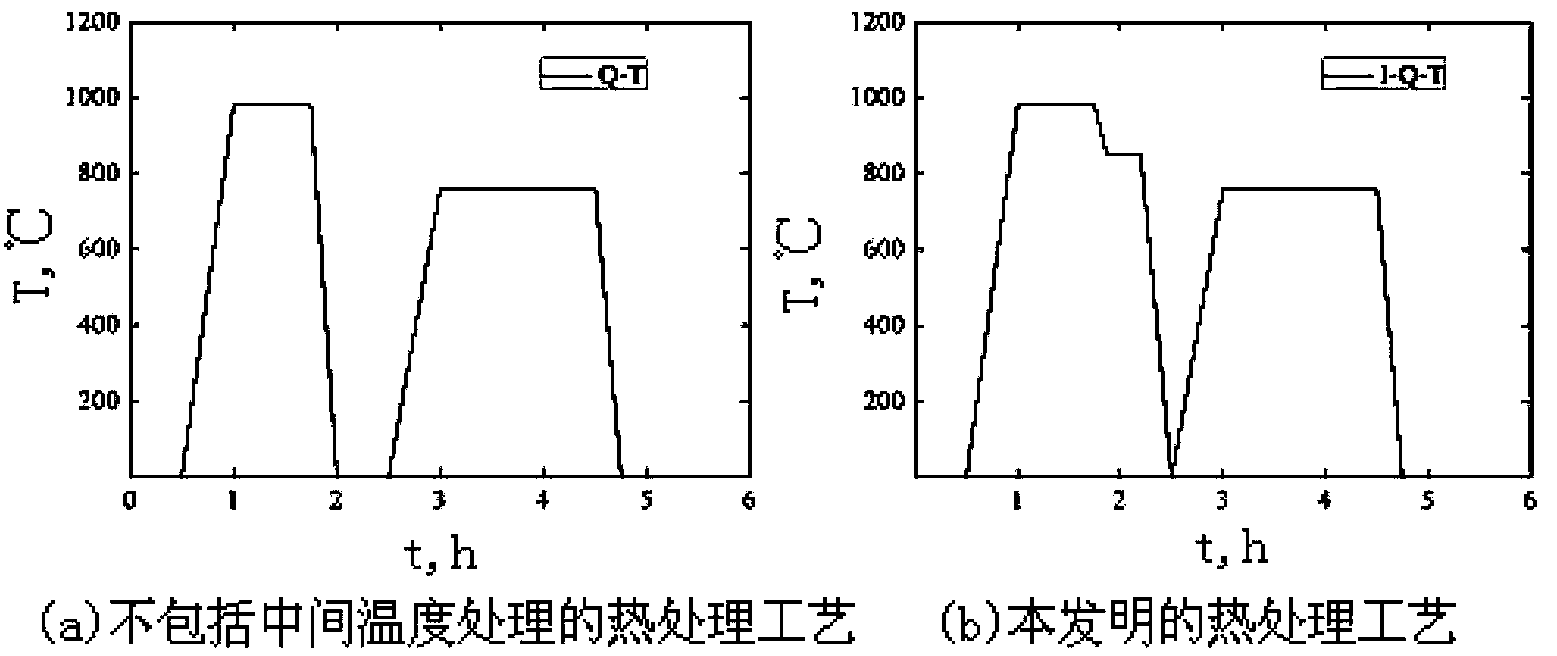

[0055] Example 2 (Influence of thermal insulation heat treatment on high temperature mechanical properties)

[0056] Sample 1: low activation steel prepared in Example 1

[0057] Sample 2: raw materials: C: 0.085% by weight; N: 0.028% by weight; Ta: 0.035% by weight; Mn: 0.51% by weight; W: 1.51% by weight; Cr: 9.12% by weight; And the total amount of S: ≤0.010% by weight; the rest is Fe. After casting, forging and rolling the raw materials of the above ingredients into 16 mm steel plates (the effective thickness is 16), the following heat treatment process is adopted: at 1000 ° C for 45 minutes, then air cooled to room temperature; then heated to 750 ° C ~ Temper at 755°C for 75 minutes, then air cool to room temperature. Finally, sample 2 was prepared.

[0058] Determination of high temperature creep mechanical properties:

[0059] Experimental conditions: 550°C, 270MPa. The specific experimental method is carried out according to GB / T2039-2012.

[0060] The measuremen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com