Process of extracting collagen from waste chrome leather scraps

A technology of collagen and process method, which is applied in the field of collagen extraction process, can solve the problems of low yield, poor quality, low viscosity of gelatin, etc., and achieve the effect of improving extraction rate and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The process flow is chrome leather shavings→pretreatment→alkaline hydrolysis→centrifugation, and gelatin and filtrate are obtained after centrifugation; gelatin is desalted and dried, filtrate is hydrolyzed by enzymes→centrifugation, and amino acids, polypeptides and chromium cakes are obtained after centrifugation.

[0014] Chromium leather shavings contain a certain amount of impurities such as inorganic salts, so it is necessary to pretreat them with water. Washing can reduce the ash content, chromium content and free acid in the chrome leather shavings, help to reduce the ash content in the hydrolyzed protein product, and at the same time reduce the impact of these impurities on the later alkaline enzyme hydrolysis.

[0015] The washing pretreatment process is to wash twice with water, each time for 30 minutes, the water consumption is 300% (based on the dry basis of leather shavings), and the nonionic surfactant is 0.5%.

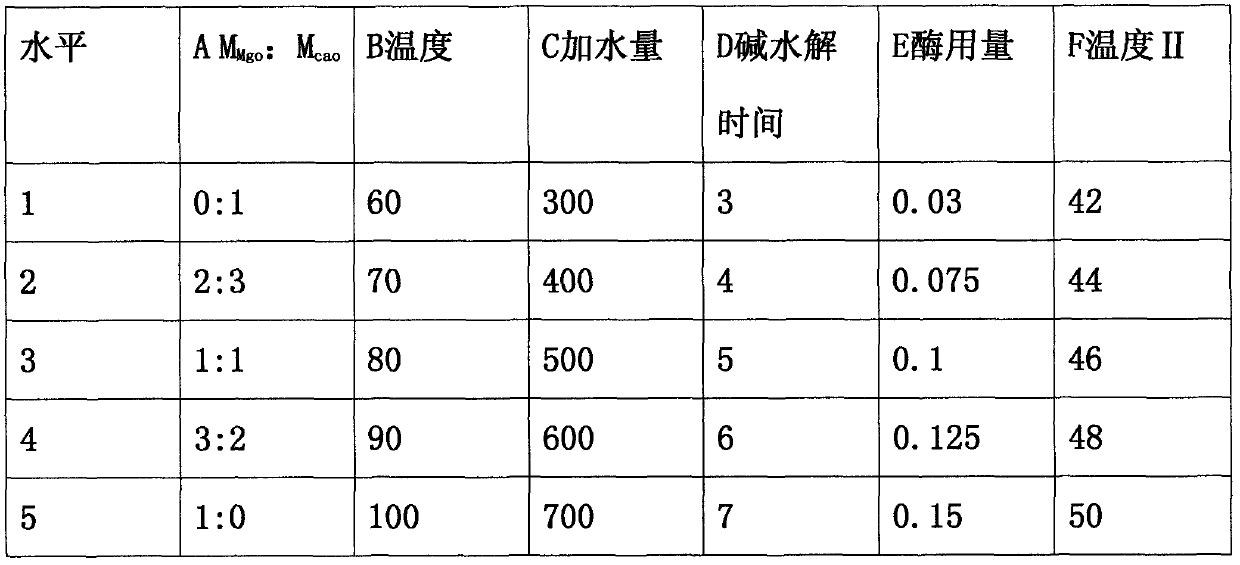

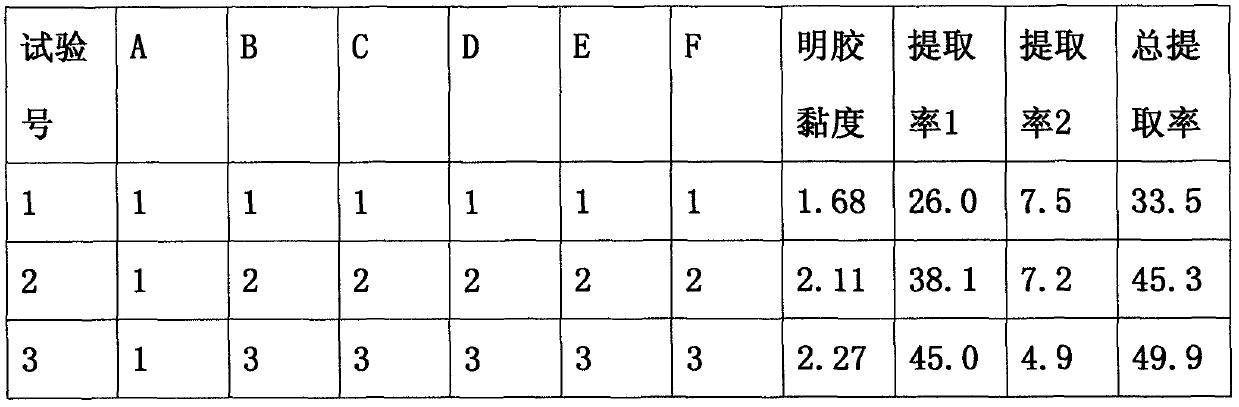

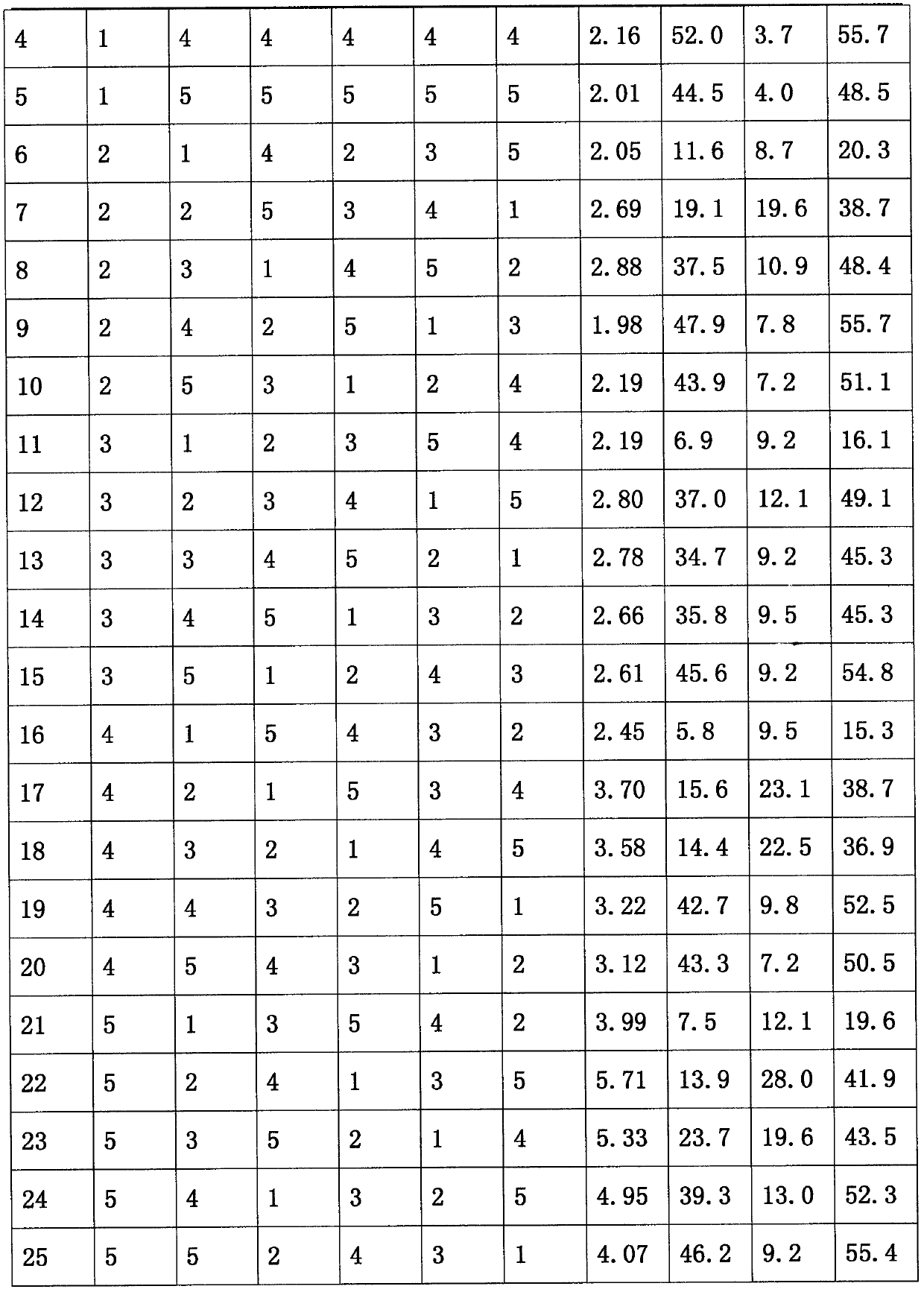

[0016] The main factors affecting the yiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com