Salt-free high-chrome-absorption chrome tanning method for animal skin and application of salt-free high-chrome-absorption chrome tanning method

An animal skin, high absorption technology, applied in application, leather impregnation, chemical treatment before tanning, etc., can solve problems such as reducing product performance, affecting chromium penetration, and chromium excessively combining, improving overall performance and simplifying alkali extraction operations. , Conducive to the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 - Salt-free chrome high absorption chrome tanning of dairy cow sofa leather

[0050] The dairy cowhide used as tanning is processed through soaking, dehairing, liming, deliming, and softening processes, and then proceeds to the following two steps.

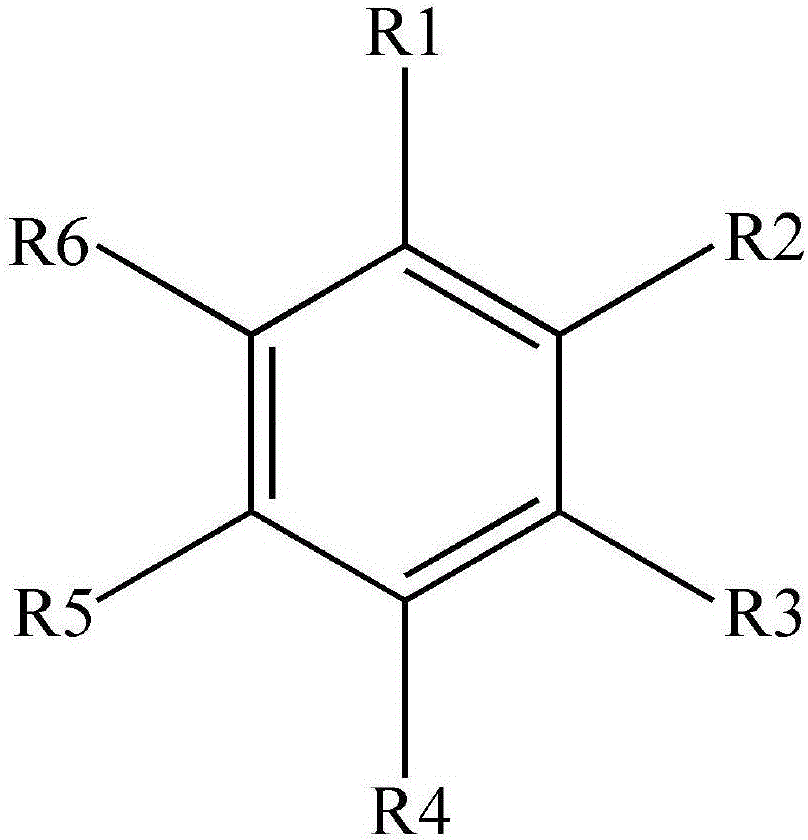

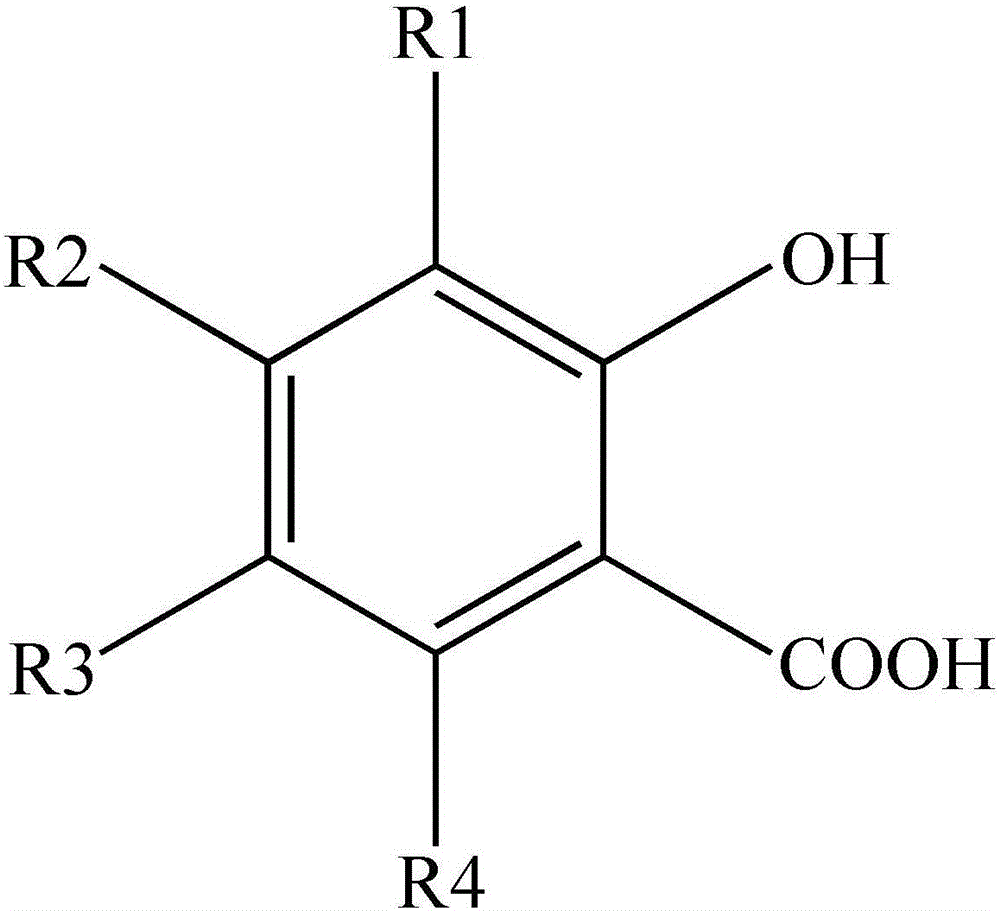

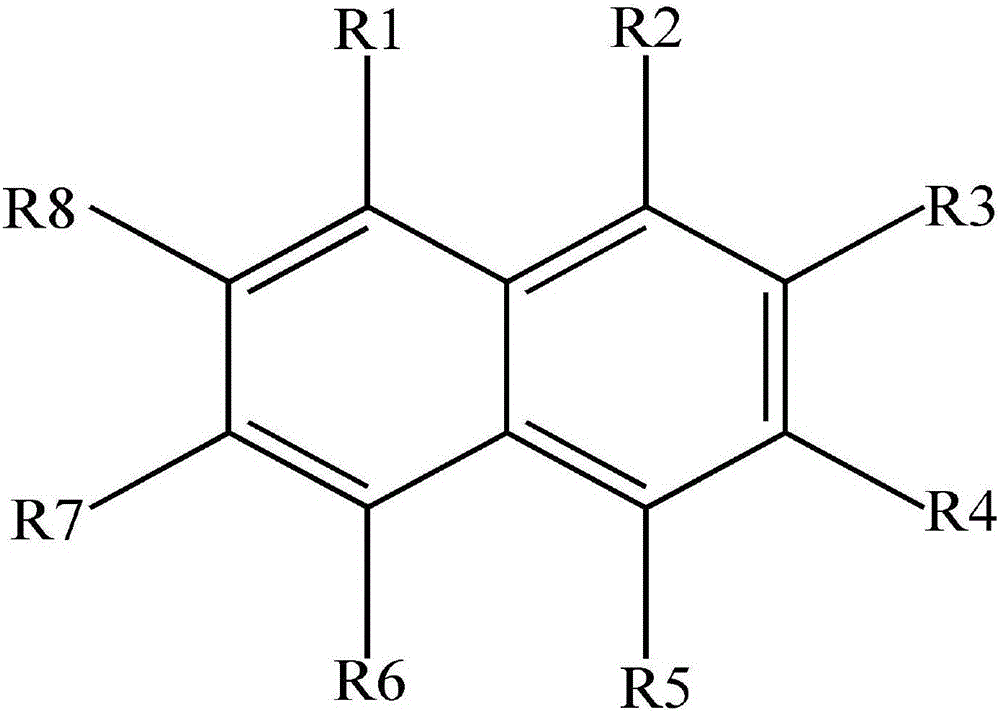

[0051] (1) softening and acidification of bare skin

[0052] After immersion, dehairing, liming, deliming, and softening processes, 100kg of cowhide is put into a drum, and about 50kg of water is added, and the temperature is adjusted to about 22°C. Add about 1.5 kg of naphthalenesulfonic acid. kg, rotate for about 180 minutes, and then rotate intermittently, the total time is about 24 hours, the softened bare skin is completely acidified, and the pH value of the bath is controlled to be about 4.5.

[0053] (2) Acidification of bare leather chrome tanning

[0054] Add DowellorGHL (a kind of anti-electrolyte fatliquor, Sichuan Dawei Technology Co., Ltd.) 2.0kg, rotate for about 30 minutes, add ChromosalB (a kind ...

Embodiment 2

[0055] Example 2—Salt-free chrome high absorption chrome tanning of cattle shoe upper leather

[0056] The yellow cowhide used for tanning is processed by soaking in water, dehairing, liming, deliming, and softening, and then proceeds to the following two steps.

[0057] (1) softening and acidification of bare skin

[0058] After soaking, dehairing, liming, deliming, and softening processes, 100kg of cowhide is put into the drum, and about 40kg of water is added, and the temperature is adjusted to about 20°C, and α-naphtholsulfone is added. Acid 1.2kg, rotate for about 240 minutes, and then rotate intermittently, the total time is about 24 hours, the softened bare skin is completely acidified, and the pH value of the bath is controlled at about 5.0.

[0059] (2) Chrome tanned

[0060] Add DowellorGHL (a kind of anti-electrolyte fatliquoring agent, Sichuan Dawei Science and Technology Co., Ltd.) 3.0kg, rotate 40 minutes, add ChromosalB (a kind of alkalinity is 33%, Cr 2 o 3...

Embodiment 3

[0061] Example 3—Salt-free chromium high absorption chrome tanning of goat garment leather

[0062] After the goatskin used as tanning is soaked in water, depilated, limed, delimed and softened, the following two steps are carried out.

[0063] (1) softening and acidification of bare skin

[0064] 100kg of goatskin after soaking, dehairing, liming, deliming and softening process is put into the drum, add about 50kg of water, adjust the temperature to about 20°C, add dihydroxyphenyl sulfone Acid 1.2kg, rotate for about 240 minutes, and then rotate intermittently, the total time is about 24 hours, the softened bare skin is completely acidified, and the pH value of the bath is controlled at about 5.5.

[0065] (2) Chrome tanned

[0066] Add ChromosalB (a basicity of 33%, Cr 2 o 3 Content is 26% chrome tanning agent, Lanxess Company) 3.5kg, rotate about 240 minutes. After the chrome tanning agent has completely penetrated into the skin, add 0.1-0.3kg of baking soda in 1-2 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com