Method and device for recovering ammonia nitrogen from oxidative dehydration catalyst preparation wastewater

A technology for oxidative dehydrogenation and ammonia nitrogen recovery, applied in chemical recovery, chemical instruments and methods, ammonia preparation/separation, etc., to solve storage risks and reduce preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

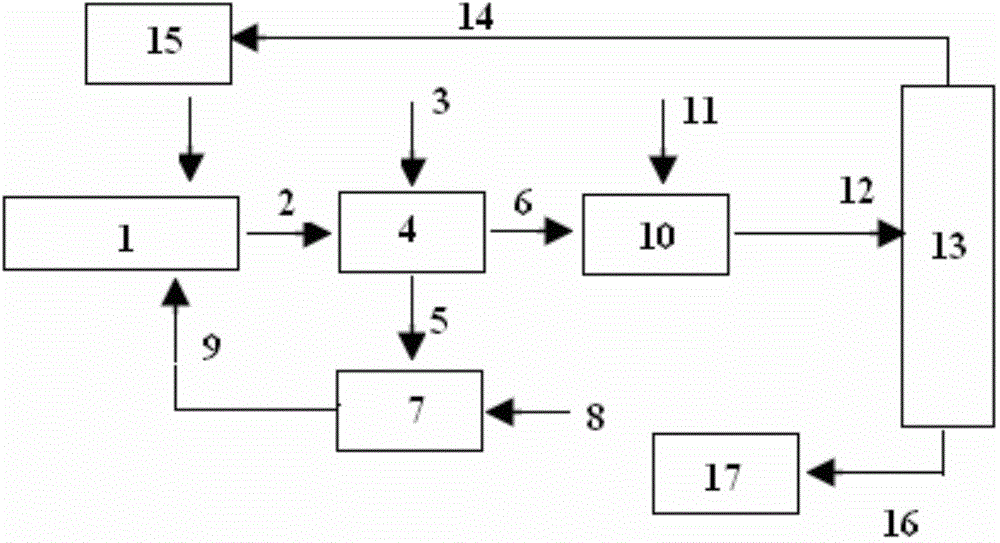

[0065] Oxidative dehydrogenation catalyst preparation device (1) produced high-concentration wastewater (2) in the preparation process of W-201, collected 8000ml, ammonia nitrogen concentration was 3.05%, and continuously fed carbon dioxide gas (3) precipitation 2h into the carbon dioxide precipitation device (4) , The product zinc carbonate precipitate (5) obtained by filtration enters the precipitation collection container (7), and the obtained metal-removed wastewater (6) is collected in the metal-removed wastewater storage tank (10), and added to the wastewater storage tank (10) 6% lye (sodium hydroxide solution) (11), the solution after lye neutralization (ammonia nitrogen recovery tower feed) (12) is injected into the 30mm diameter ammonia rectification tower with a metering pump at a flow rate of 480g / h ( In 13), the tower is equipped with 2mmθ mesh ring packing, the number of theoretical plates is 35, the feed inlet is at the upper end 1 / 3, the reflux ratio is 0.5, and 1...

Embodiment 2

[0068] Oxidative dehydrogenation catalyst preparation device (1) produced high-concentration wastewater (2) in the preparation process of W-201, collected 15000ml, containing ammonia nitrogen concentration of 5.98%, and continuously fed carbon dioxide gas (3) precipitation 2h into the carbon dioxide precipitation device (4) , The product zinc carbonate precipitate (5) obtained by filtration enters the precipitation collection container (7), and the obtained metal-removed wastewater (6) is collected in the metal-removed wastewater storage tank (10), and added to the wastewater storage tank (10) 10% lye (sodium hydroxide solution) (11), the solution after lye neutralization (ammonia nitrogen recovery tower feed) (12) is injected into the 30mm diameter ammonia rectification tower with a metering pump at a flow rate of 680g / h ( In 13), the tower is equipped with 2mmθ mesh ring packing, the number of theoretical plates is 35, the feed inlet is at the upper end 1 / 3, the reflux ratio i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com