Waste gas treatment system for VOCs recovery

A waste gas treatment and waste gas technology, which is applied in gas treatment, air quality improvement, dispersed particle filtration, etc., can solve problems such as environmental pollution, rising unit consumption cost of solvent production, etc., and achieve the effect of enhanced recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific examples.

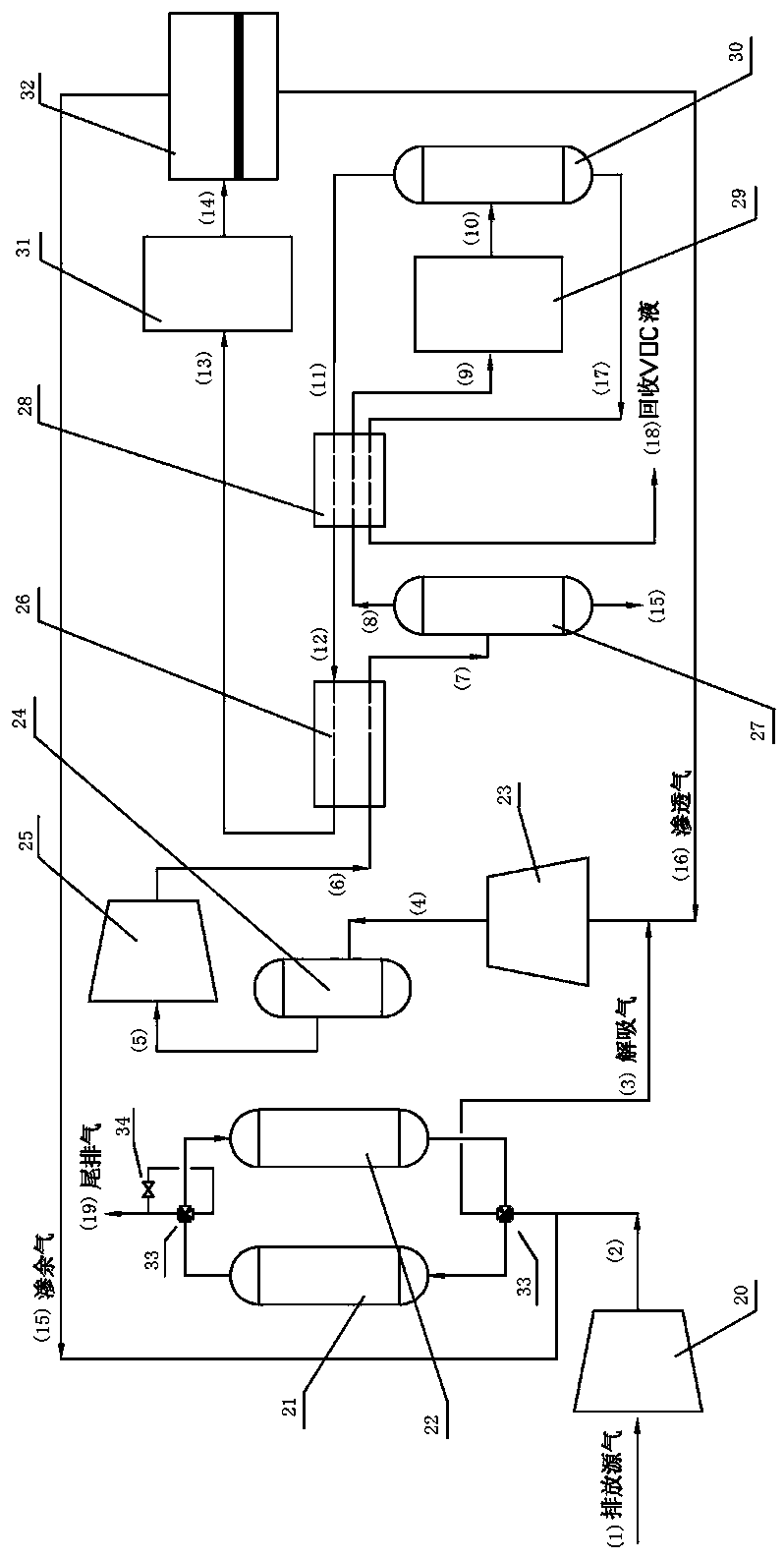

[0024] Such as figure 1 As shown, a waste gas treatment system for VOCs recovery, the waste gas (1) is sent to the adsorption equipment after the waste gas (1) is first passed through the supercharger-20 as the raw material gas, and the adsorption equipment is two groups of adsorption tanks, and the adsorption tank A 21 and adsorption tank B 22, the gas is discharged as tail gas (19) after being adsorbed by adsorption tank A 21, and the analytical gas (3) after passing through adsorption tank B 22 is pumped by vacuum pump 23 (4), and then passes through buffer tank 24. The material (5) is sent to the inlet of supercharger two 25, and the exhaust gas of supercharger two 25 (6) is sent to heat exchanger one 26 as heat flow. After heat exchange, the gas (7) first passes through the liquid separation tank one 27 tanks The liquid water (15) that is pre-cooled and separated is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com