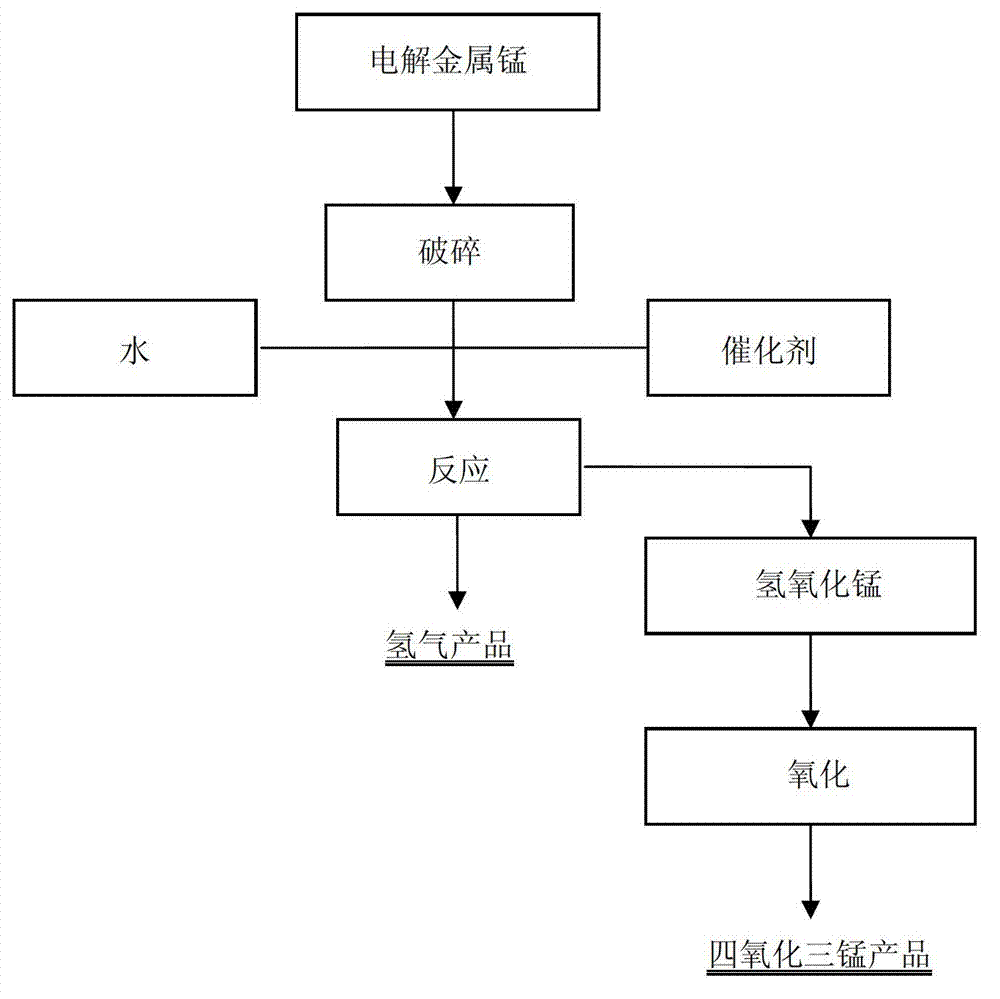

Method for preparing hydrogen in process of producing trimanganese tetroxide from electrolytic manganese metal

A technology of electrolytic manganese metal and trimanganese oxide, which is applied in the production of manganese oxide/manganese hydroxide and hydrogen, can solve problems such as combustion explosion, low hydrogen concentration, and no recycling value, and achieve energy saving and economic cost The effect of low and good economic benefits and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The method for preparing hydrogen in a kind of electrolytic manganese metal production process of manganese tetraoxide of the present embodiment comprises the following steps:

[0042] (1) Weigh 1000g of electrolytic manganese metal, crush it in a ball mill for 1 hour to make electrolytic manganese metal powder, and use an analytical sieve to test that its particle size is 100% less than 100 μm;

[0043] (2) Add 3L of distilled water to the electrolytic manganese metal powder to prepare a slurry, and put the slurry into the hydrogen generator;

[0044] (3) Weigh 10g of ammonium chloride, add it to the slurry, control the temperature of the system at 65°C, stir for 1 hour, and control the pH at 6. After the slurry is hydrolyzed, manganese hydroxide will be generated and hydrogen will be released;

[0045] (4) After discharging the gas released in the first 3 minutes of reaction, use a collection bag to collect the gas released in the subsequent reaction, and pass the man...

Embodiment 2

[0048] The method for preparing hydrogen in a kind of electrolytic manganese metal production process of manganese tetraoxide of the present embodiment comprises the following steps:

[0049] (1) Weigh 2000 g of electrolytic manganese metal, crush it in a ball mill for 1.5 hours to make electrolytic manganese metal powder, and use an analytical sieve to test that its particle size is 100% less than 75 μm;

[0050] (2) Add 5L of distilled water to the electrolytic metal manganese powder to prepare a slurry, and put the slurry into the hydrogen generator;

[0051] (3) Weigh 25g of ammonium sulfate, add it to the slurry, control the system temperature at 80°C, stir for 1 hour, and control the pH at 7. After the slurry is hydrolyzed, manganese hydroxide will be generated and hydrogen will be released;

[0052](4) After discharging the gas released in the first 3 minutes of reaction, use a collection bag to collect the gas released in the subsequent reaction, and pass the manganese...

Embodiment 3

[0055] The method for preparing hydrogen in a kind of electrolytic manganese metal production process of manganese tetraoxide of the present embodiment comprises the following steps:

[0056] (1) Weigh 1500g of electrolytic manganese metal, add 4L of distilled water to make a slurry;

[0057] (2) Put the slurry into a ball mill and grind it for 1 hour to make a slurry with a particle size of 100% less than 60 μm, and put the slurry into a hydrogen generator;

[0058] (3) Weigh 20g of manganese chloride, add it to the slurry, control the system temperature at 85°C, stir for 1 hour, and control the pH at 9. After the slurry is hydrolyzed, manganese hydroxide will be generated and hydrogen will be released;

[0059] (4) After discharging the gas released in the first 3 minutes of reaction, use a collection bag to collect the gas released in the subsequent reaction, and pass the manganese hydroxide generated by the reaction into compressed air for oxidation reaction at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com